Sludge collection and treatment equipment

A silt and equipment technology, applied in the field of silt collection and treatment equipment, can solve the problems of poor versatility of salvage scenarios, large water content in the silt, and low salvage efficiency, and achieve long-term efficient use, energy saving, and easy equipment avoidance. effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

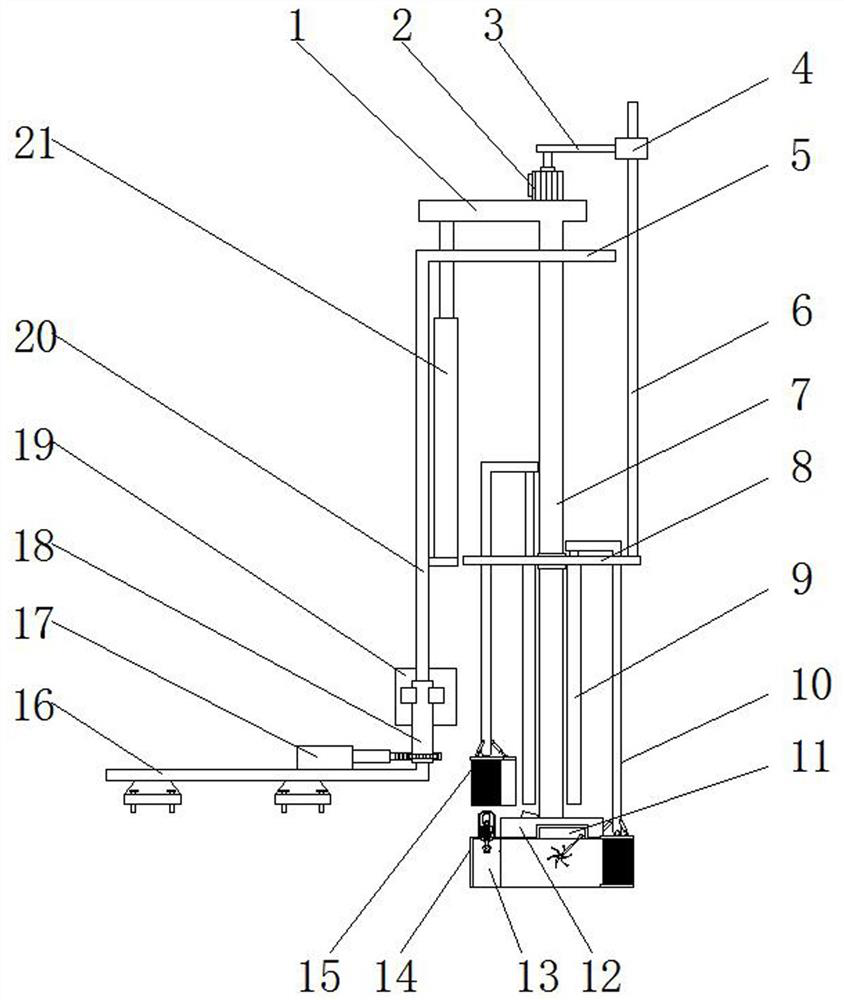

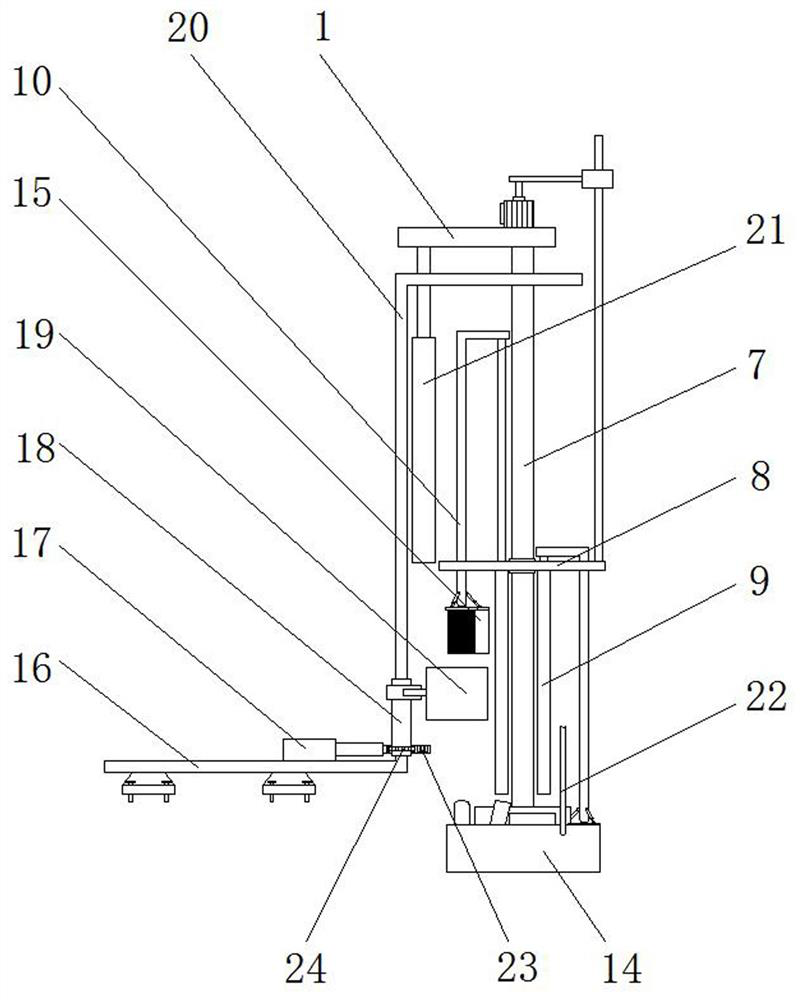

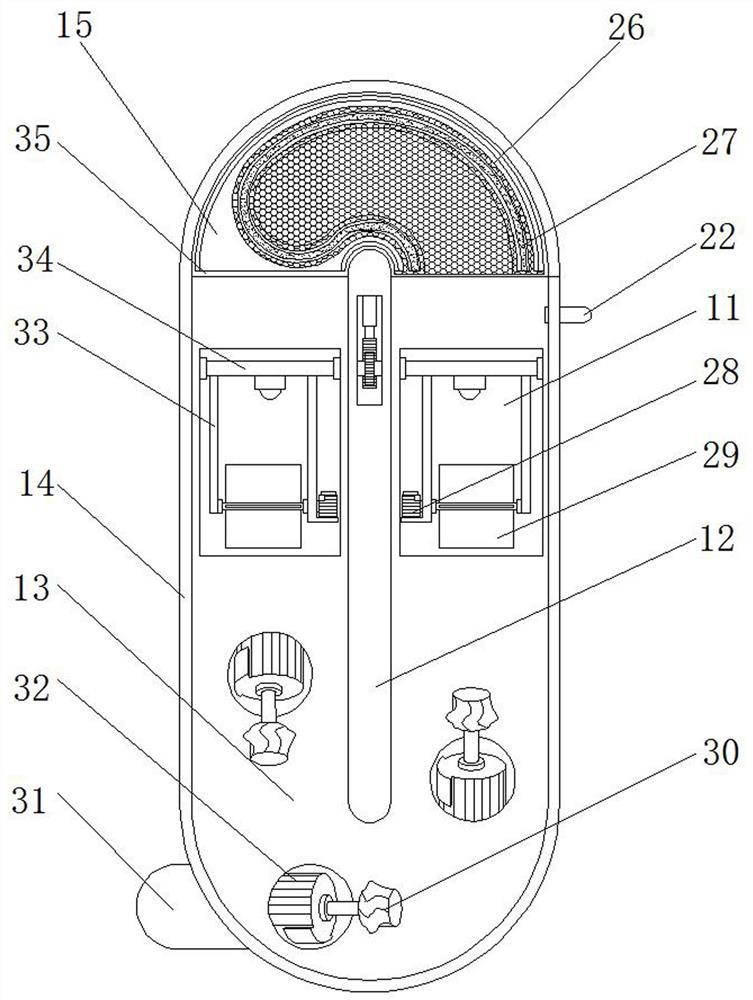

[0028] See Figure 1-7In one embodiment of the present invention, a silt collection control device includes a fixing plate 16, and one end of the fixed plate 16 is perpendicularly welded to the column 20, and the column 20 is kept parallel to the fixed plate 16 welding. On the plate 5, the mounting plate 5 is vertically inserted with the main rod 7, and the main rod 7 is arranged parallel to the column 20, and the column 20 is equipped with a hydraulic cylinder 12 for driving the main roste 7 lifting and lowering. The output end extends to the mounting plate 5 and connected between the main rod 7, and the bottom end of the main roster 7 is welded to the separator 12, and the outer side welding of the separator 12 has a silt cover 14, the mud cover 14 and The partition 12 wall thickness is prone to the collection area after the sludge extrusion, that is, the thickness is large and the resistance is large and easy to affect the sealing. Therefore, the silt cover 14 and the bottom end...

Embodiment 2

[0030] The present embodiment differs from the first embodiment in that the outlet 35 of the top of the sludge 14 has a pair of symmetrical arrangement, and 4 of the secondary rod 10 and the silt collection assembly on the turntable 8, two or two silt collecting components. The servo on both sides of the inlet 35 is used alternately, i.e., two servo, one side of the projecting and exit 35, respectively, sludge collection and replacement, where the other two servo is used for silt collection and replacement, then When the rotation of the turntable 8 is reduced, the receiving component is also arranged in two groups, which can be more efficiently used for flow collection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com