Elastic breathable fabric based on hollow covering yarns and preparation process of elastic breathable fabric

A preparation process and technology of core-spun yarn, applied in the directions of yarn, textiles and papermaking, can solve the problem of insufficient dispersion of the resilience performance of the covered yarn, and achieve smooth structure ventilation, stable bonding, and improved resilience. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

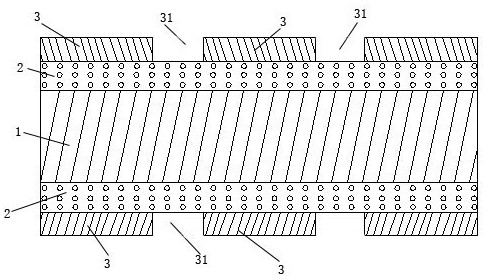

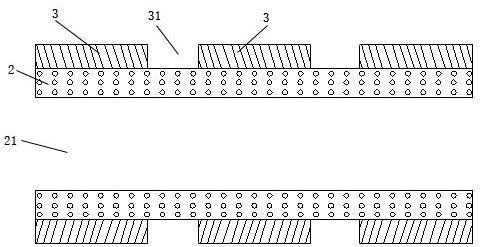

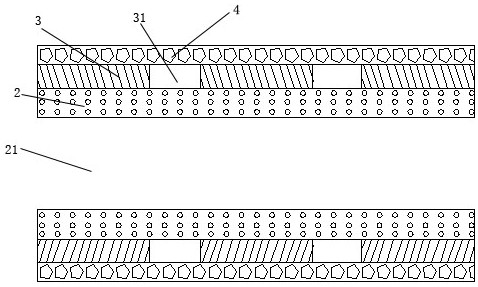

[0027] Such as Figures 1 to 3 Shown, a kind of elastic breathable fabric based on hollow type core-spun yarn, described fabric is woven by hollow type core-spun yarn; Described hollow type core-spun yarn comprises XLA elastic fiber layer 2, annular bonding layer 3, The flax fiber layer 4; the inside of the XLA elastic fiber layer 2 is a hollow structure 21; the XLA elastic fiber layer 2 is uniformly provided with a plurality of annular adhesive layers 3 around the outside along its length direction; between the annular adhesive layers 3 An annular air-permeable gap 31 is provided; flax fiber layer 4 is arranged around the outside of the annular adhesive layer 3; the components and parts by weight of the annular adhesive layer 3 are as follows: 45 parts of epoxy resin, 15 parts of plasticizer, 3 parts of dispersant. Further, the plasticizer is DOP plasticizer. Further, the dispersant is polyacrylamide.

Embodiment 2

[0029] Such as Figures 1 to 3 Shown, a kind of elastic breathable fabric based on hollow type core-spun yarn, described fabric is woven by hollow type core-spun yarn; Described hollow type core-spun yarn comprises XLA elastic fiber layer 2, annular bonding layer 3, The flax fiber layer 4; the inside of the XLA elastic fiber layer 2 is a hollow structure 21; the XLA elastic fiber layer 2 is uniformly provided with a plurality of annular adhesive layers 3 around the outside along its length direction; between the annular adhesive layers 3 An annular air-permeable gap 31 is provided; flax fiber layer 4 is arranged around the outside of the annular adhesive layer 3; the components and parts by weight of the annular adhesive layer 3 are as follows: 50 parts of epoxy resin, 18 parts of plasticizer, Dispersant 5 parts. Further, the plasticizer is DOP plasticizer. Further, the dispersant is polyacrylamide.

Embodiment 3

[0031] Such as Figures 1 to 3 Shown, a kind of elastic breathable fabric based on hollow type core-spun yarn, described fabric is woven by hollow type core-spun yarn; Described hollow type core-spun yarn comprises XLA elastic fiber layer 2, annular bonding layer 3, The flax fiber layer 4; the inside of the XLA elastic fiber layer 2 is a hollow structure 21; the XLA elastic fiber layer 2 is uniformly provided with a plurality of annular adhesive layers 3 around the outside along its length direction; between the annular adhesive layers 3 An annular air-permeable gap 31 is provided; flax fiber layer 4 is arranged around the outside of the annular adhesive layer 3; the components and parts by weight of the annular adhesive layer 3 are as follows: 50 parts of epoxy resin, 18 parts of plasticizer, Dispersant 5 parts. Further, the plasticizer is DOP plasticizer. Further, the dispersant is polyacrylamide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com