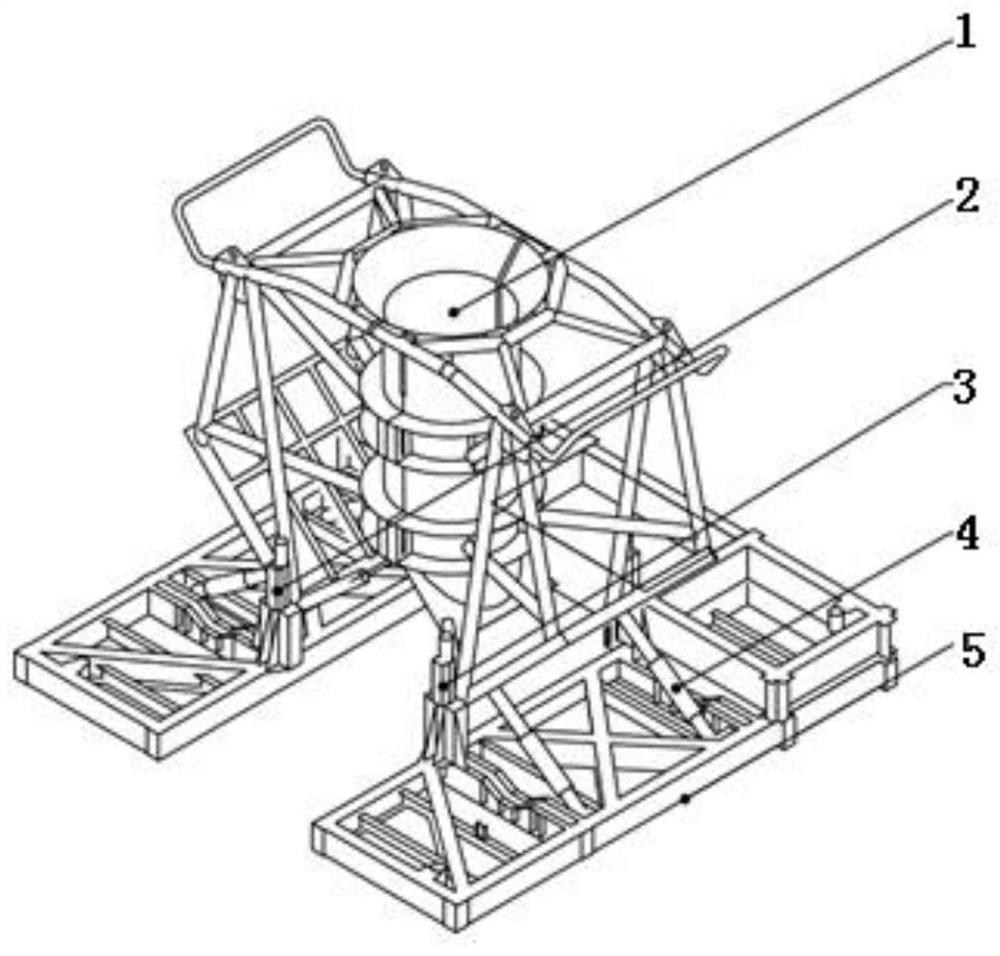

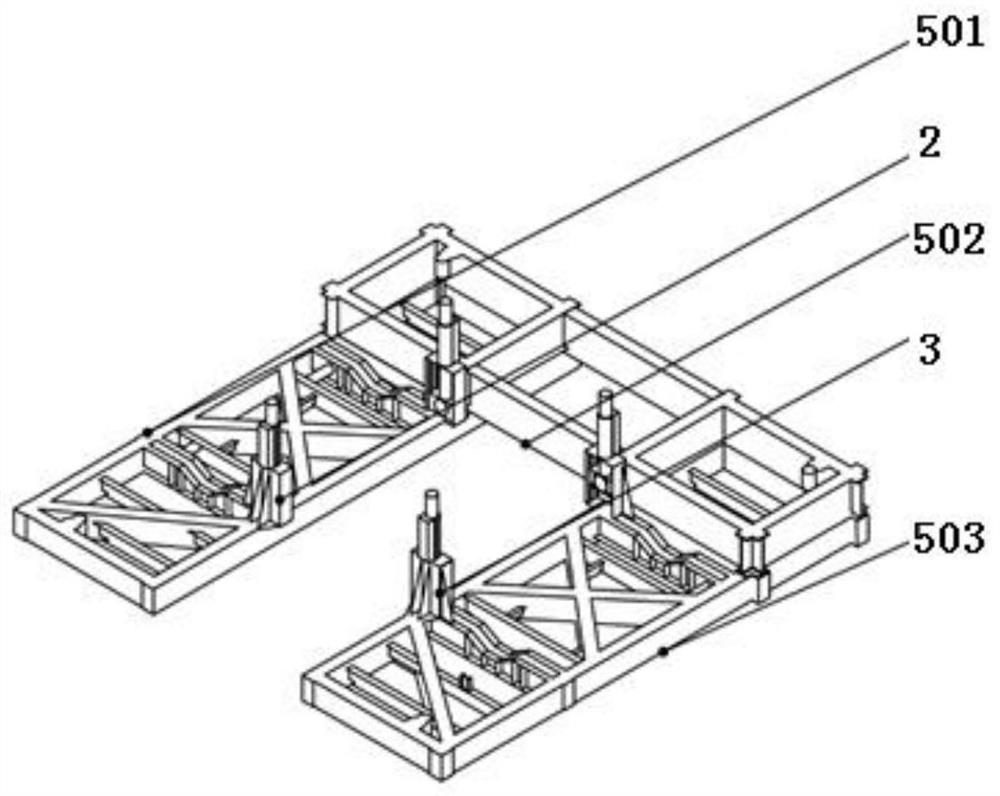

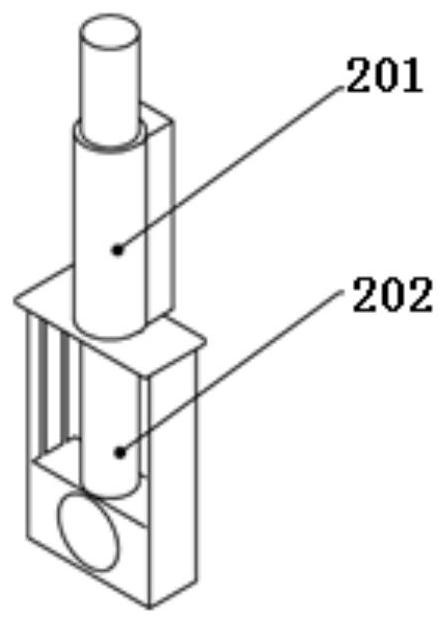

Angle-adjustable underwater anchor pile guide frame and operation method thereof

An angle adjustment and guide frame technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of inconvenient installation of anchor piles, no angle adjustment function, increase engineering cost, etc., so as to eliminate operation risks and shorten working hours. , the effect of reducing engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the purpose, technical solutions and advantages of the present invention clearer, the technical solutions in the present invention are clearly and completely described below. Apparently, the described embodiments are part of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by ordinary persons in the art without making creative efforts belong to the protection scope of the present invention.

[0043] Unless otherwise defined, the technical terms or scientific terms used in the present invention shall have the usual meanings understood by those skilled in the art to which the present invention belongs. "First", "second", "third", "fourth", "upper", "lower", "left and right" and similar words used in the present invention do not imply any order, quantity or importance , but only used to distinguish different components. "Comprising" or "comprising" and similar word...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap