High pour-point oil sludge profile control ground injection heating and heat preservation system and method

A technology of heating and heat preservation and high pouring oil, which is applied in chemical instruments and methods, earthwork drilling, isolation devices, etc., can solve the problems that high pouring oil sludge cannot be injected normally, and achieve the effect of harmless treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

[0050] Due to the oil properties of high pour point oil, the freezing point is high, and it is in a solid state at normal temperature. The ground must be heated and kept warm during injection. The problem that the high pour point oil sludge cannot be injected normally.

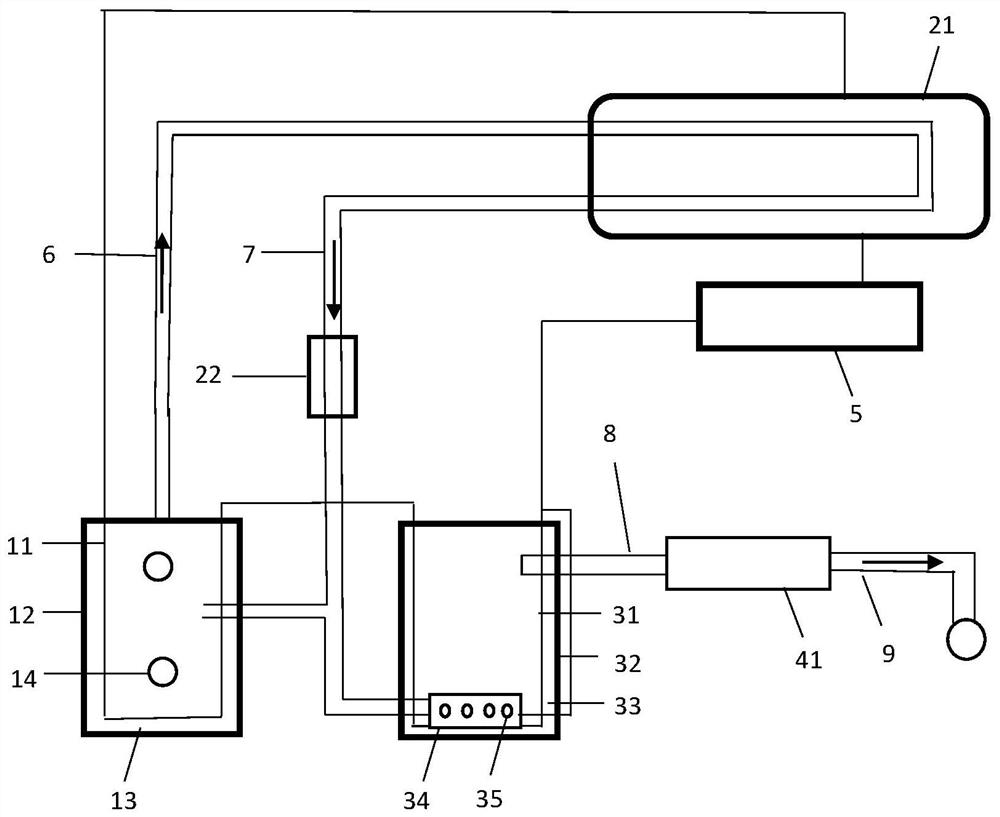

[0051] Specifically, combined with figure 1 , a high pour point oil sludge profile control surface injection heating and heat preservation system, comprising: a sludge profile control agent preparation device, a circulation heating device, a filtering device and an injection device;

[0052]The discharge port of the oil sludge profile control agent pre...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap