Pure-sludge-fired circulating fluidized bed boiler

A circulating fluidized bed and boiler technology, applied in incinerators, combustion methods, combustion types, etc., to achieve stable and safe operation and reduce air pollutant emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

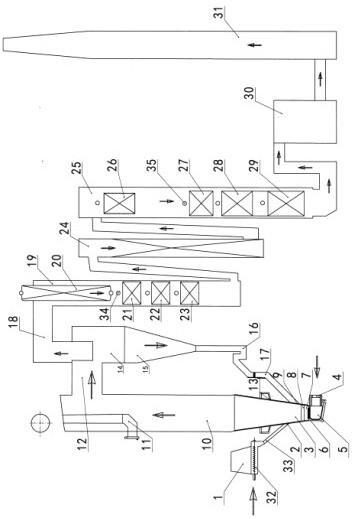

[0014] The present invention will be described in detail below with reference to the accompanying drawings:

[0015]A circulating fluidized bed boiler of pure burn, including dry sludge bin 1, circulating fluidized bed boiler heat insulation furnace, cyclone separator, tail first flue 19, the second flue of the tail, the third smoke Tao 25, the bag dust collector 30 and the chimney 31, in the heat-conducting furnace of the circulating fluidized bed boiler, provided with a furnace-clad phase pressure zone 3 and furnace rolling phase zone 10, a smoke outlet in the circulating fluidized bed boiler 12 is connected to the cyclone separator, the cyclone separator is connected to the tail first flue 19 through horizontal flue 18, and the tail second flue is connected to the tail port, second in the tail. Second The tail third flue 25 is connected to the smoke port of the flue, and the smoke port of the tail third flue 25 is connected to the chimney 31 by the bag type dust collector 30; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com