PCB drying device

A drying device and PCB board technology, applied in the field of PCB board manufacturing, can solve the problems of PCB board base damage, easy to be thrown, difficult to dry or dry, etc., to increase air flow, reduce local moisture, and improve drying rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

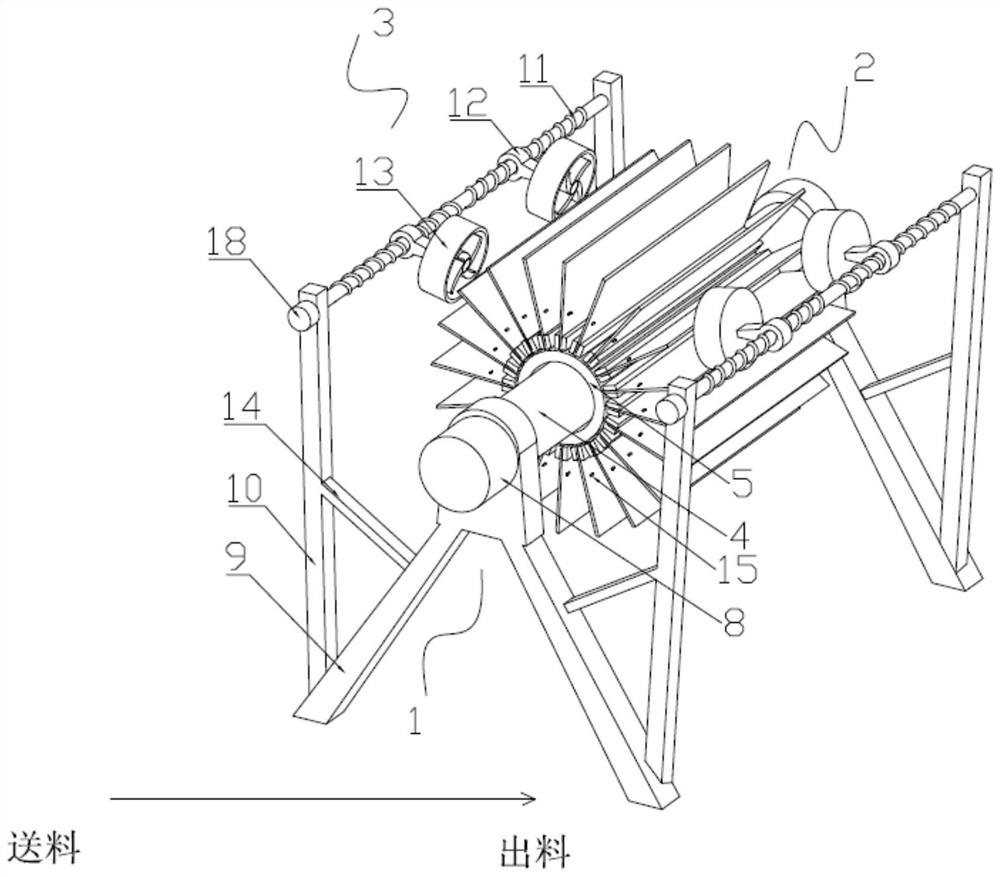

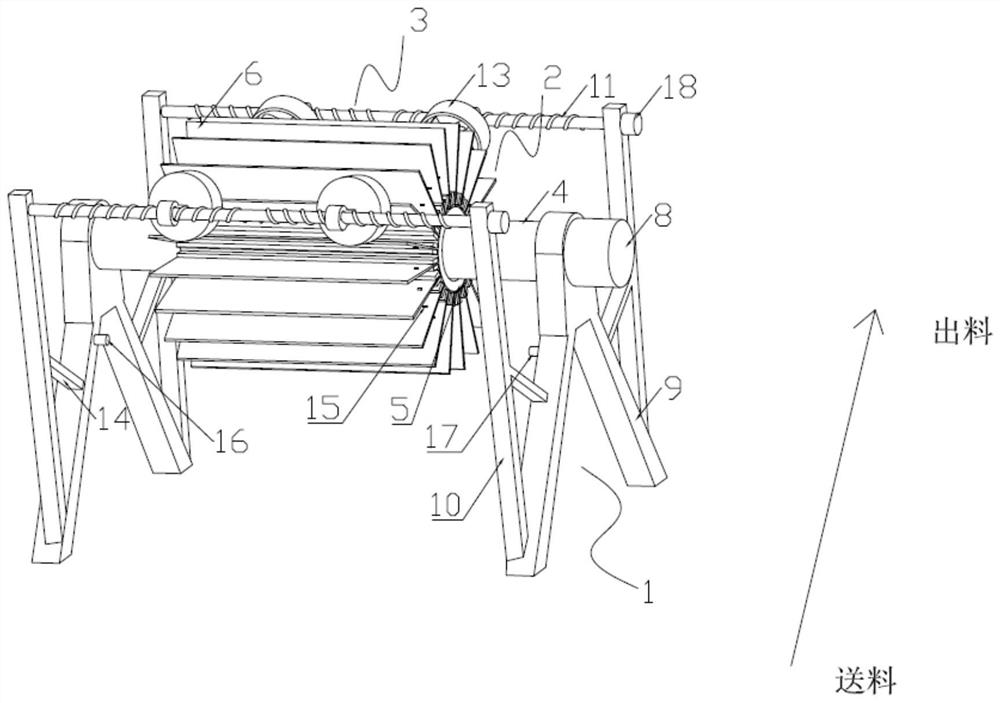

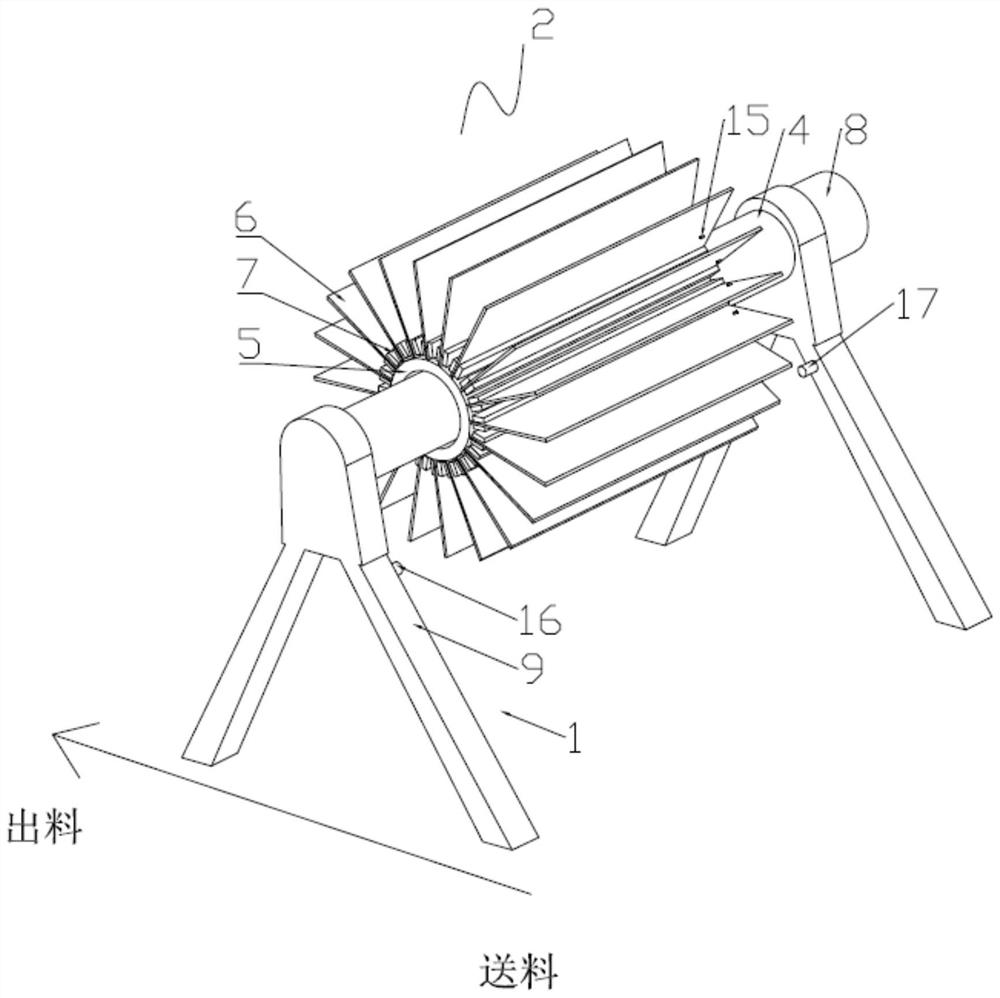

[0025] Such as Figure 1 to Figure 5 As shown, a PCB board drying device includes a frame 1, a transmission mechanism 2, and an air-drying mechanism 3;

[0026] The frame 1 is rotatably connected to the transmission mechanism 2, the transmission mechanism 2 includes a rotating shaft 4, a swivel 5, a receiving plate 6 and a slot 7, the rotating shaft 4 is rotatably connected to the frame 1 and connected to the No. 1 motor 8 The output shaft of the No. 1 motor 8 is installed on the frame 1, the rotating ring 5 is sleeved outside the rotating shaft 4 and arranged in a circular arrangement along its axial direction with several receiving plates 6 described above, and the adjacent two Slots 7 are installed between the receiving plates 6;

[0027] The air-drying mechanism 3 has two groups and is symmetrically distributed on both sides of the frame 1, wherein the air-drying mechanism 3 near the feeding end blows warm air, and the air-drying mechanism 3 near the discharging end blows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com