Wicker drying device for wickerwork products

A drying device and product technology, applied in drying, drying machine, drying gas arrangement, etc., can solve the problems affecting the production efficiency of willow weaving, re-pollution, etc., achieve continuous drying operations, improve processing efficiency, and avoid pollution problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

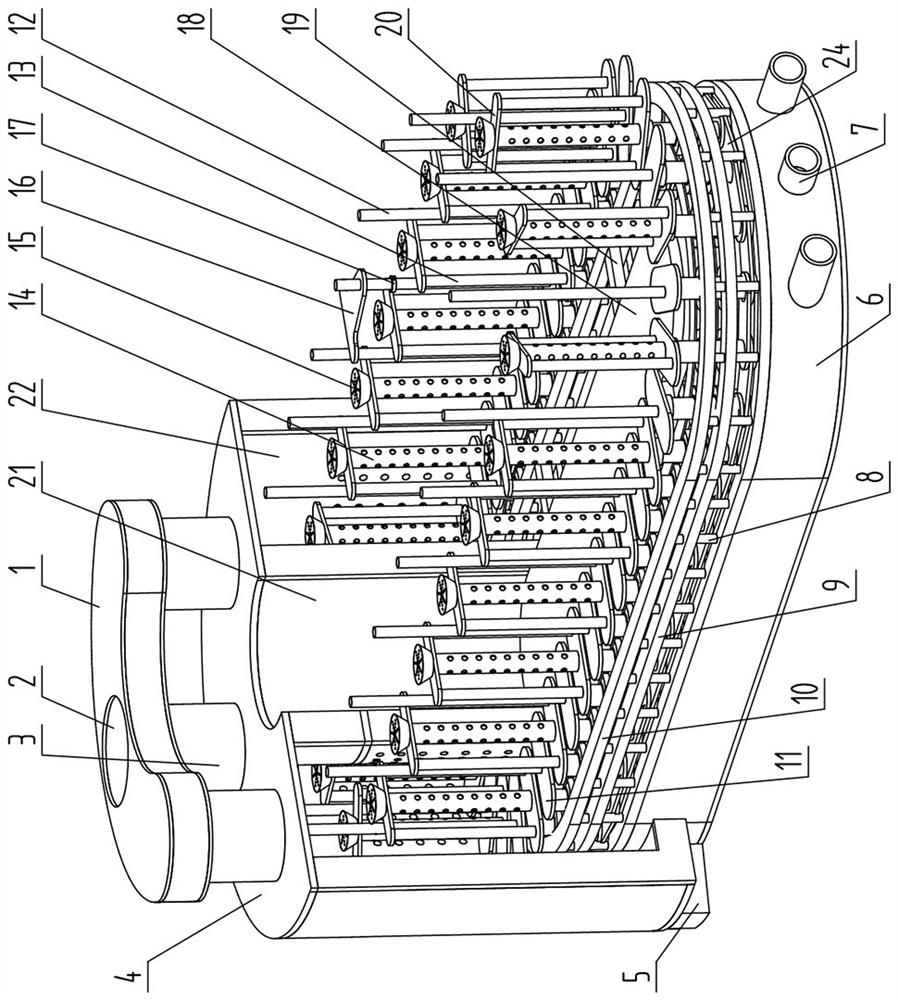

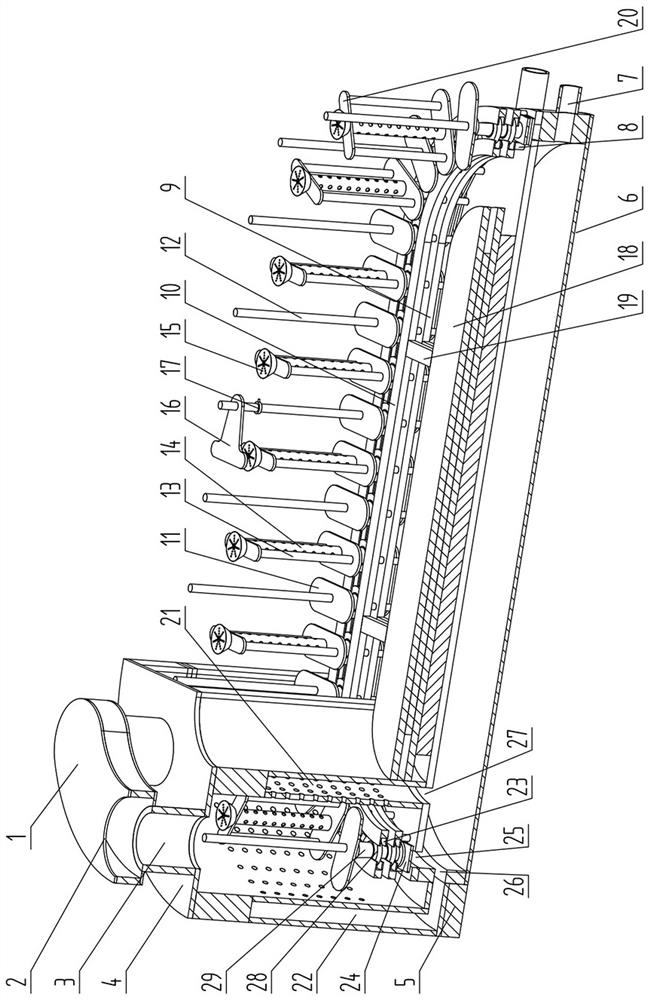

[0024] A wicker drying device used in willow products, comprising a bracket box 6 placed on a horizontal plane or a horizontal base, one end of the bracket box 6 is provided with a plurality of air intake pipes 7 communicating with its internal cavity, and the bracket One end of the box body 6 away from the air intake pipe 7 is respectively processed with a shaft body air outlet 25, an inner air outlet 26 and an outer air outlet 27, wherein the shaft body air outlet 25 is located at the top of the bracket box body 6, and the inner air outlet 26 is located at the bracket box The side of the body 6 communicates with the inside of the outer drying box 22 , and the outer air outlet 27 is located at the top of the bracket box body 6 and communicates with the inside of the inner drying box 21 . The inner drying box 21 and the outer drying box 22 constitute the drying box 4, and the cross sections of the inner drying box 21 and the outer drying box 22 are arc-shaped structures. The o...

Embodiment 2

[0026] A wicker drying device used in willow products, wherein the bracket box 6 is provided with a middle frame body 18 at the middle position above it, and the sides of the middle frame body 18 are respectively connected to the corresponding positions through frame body connecting rods 19 The bottom track 9 and the top track 10 are connected. The structure and connection relationship of the remaining parts are the same as those described in any one of the foregoing embodiments, and will not be repeated here to avoid tedious writing.

Embodiment 3

[0028] A wicker drying device used in willow products, wherein the top surface of the inner drying box 21 and the outer drying box 22 is connected with a top plate, and a top plate is provided on the top plate to communicate with the inner drying box 21 and the outer drying box. The air outlet branch pipe 3 of the space between the bottom rail 9 and the top rail 10 is accommodated between the dry box 22, and the top of the air outlet branch pipe 3 is connected with the outlet pipeline through the outlet collection box 1 and the outlet pipe connection hole 2, and the outlet pipe is connected with a draft device. The structures and connections of the remaining parts are the same as those described in any one of the foregoing embodiments, and will not be repeated here to avoid tedious writing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com