A high-accuracy and compact drainage radar flowmeter

An accuracy and flowmeter technology, applied in the direction of liquid/fluid solid measurement, measurement device, engine lubrication, etc., can solve the problems of inability to obtain measurement data, failure to meet the drainage pipe network, high maintenance and maintenance costs, and achieve accurate measurement , Improve work reliability and use flexibility, measure the effect of no blind zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

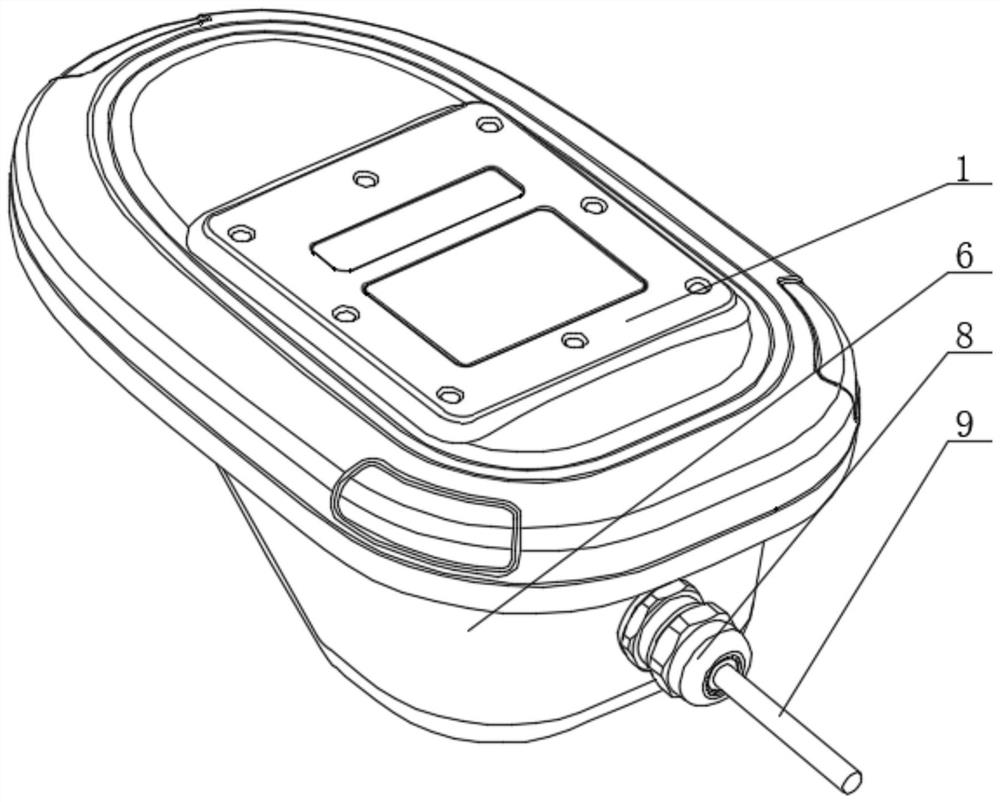

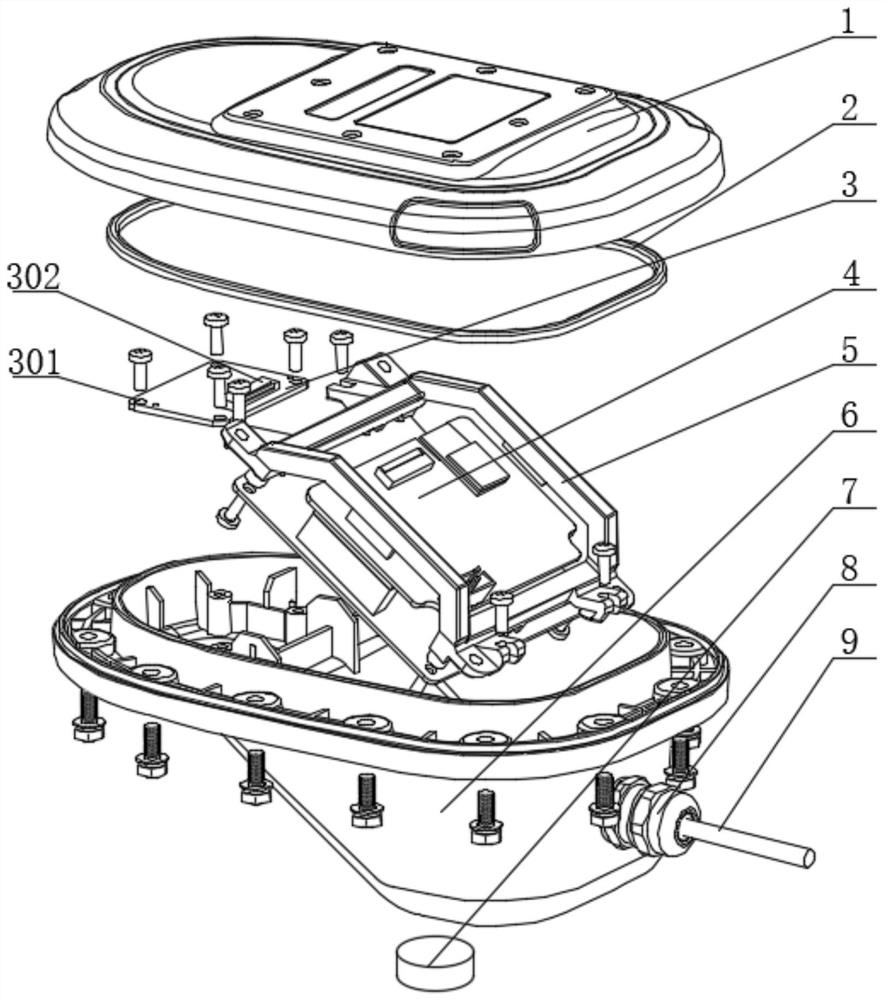

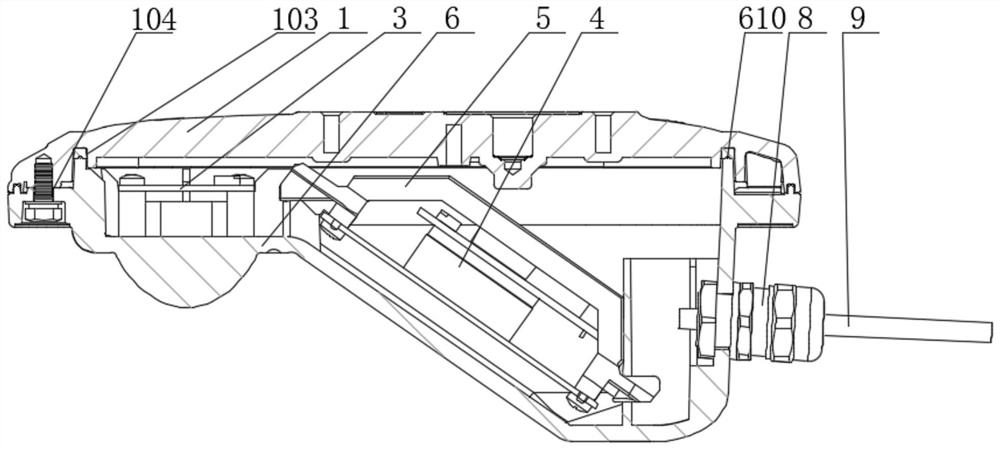

[0040] The specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0041] like Figure 1-Figure 11 As shown in the figure, the high-accuracy and compact drainage radar flowmeter of this embodiment includes a lower cover 6, the top surface of the lower cover 6 is open, a cavity is arranged inside the lower cover 6, and a fixed Bracket 5, a radar speed measuring plate group 4 is installed on the fixing bracket 5 through fasteners, the radar speed measuring plate group 4 is installed obliquely, and a radar water level plate group 3 is installed on the lower cover 6 beside the radar speed measuring plate group 4 through fasteners, The radar water level plate group 3 is connected to the radar speed measuring plate group 4 through the cable, and the upper cover 1 is installed on the top surface of the lower cover 6 through the sealing gasket 2;

[0042] The top surface of the upper cover 1 is provided with a label groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com