Intelligent power distribution cabinet for preventing instrument lens from being atomized

A technology for instrumentation and power distribution cabinets, applied in substation/distribution device casings, electrical components, substation/switch layout details, etc. It can solve problems such as poor sealing and data reading, achieve a good limit effect, and speed up the flow rate. , good dustproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

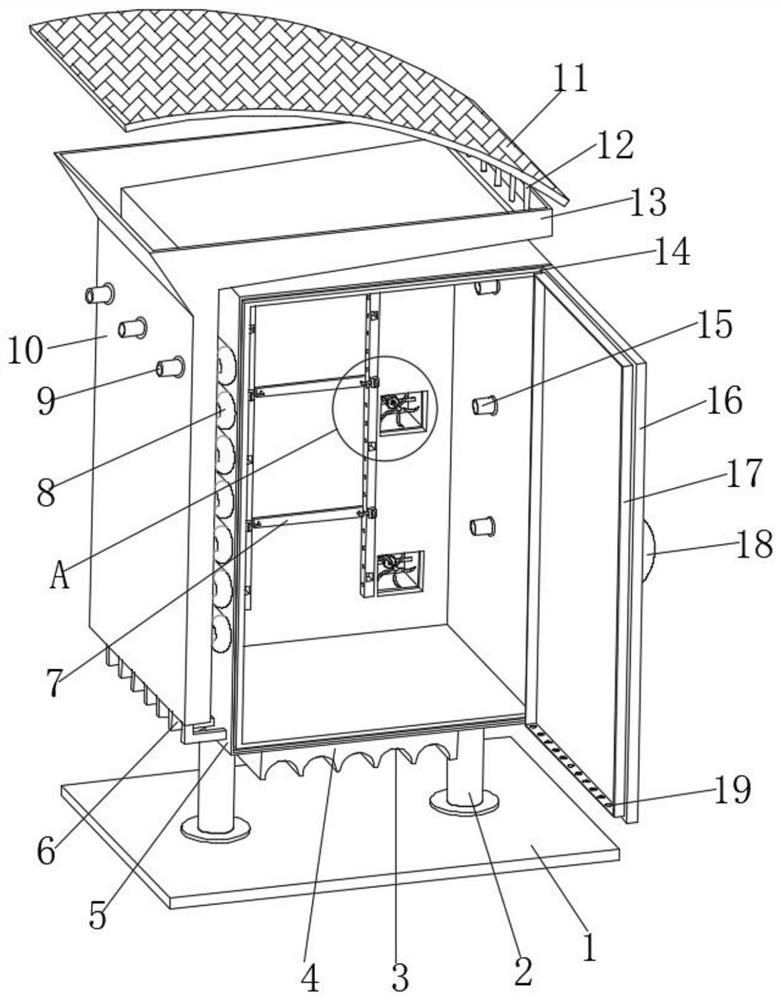

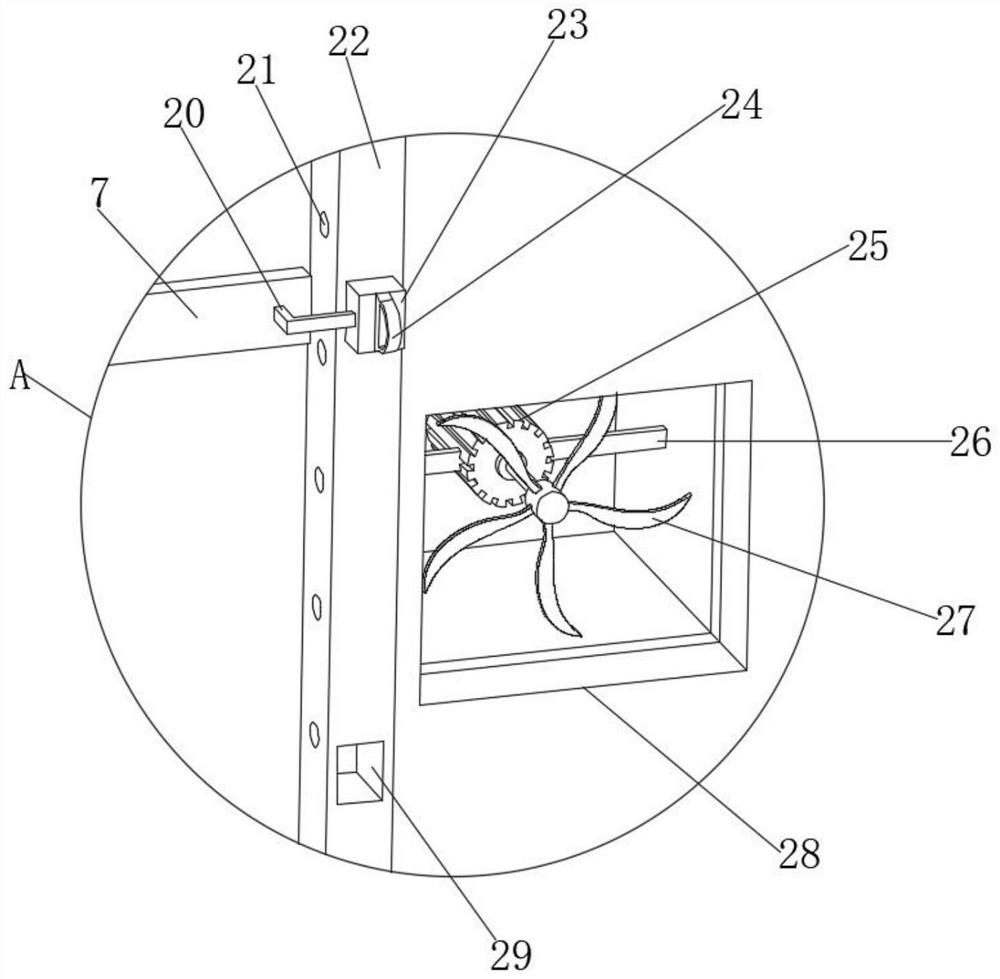

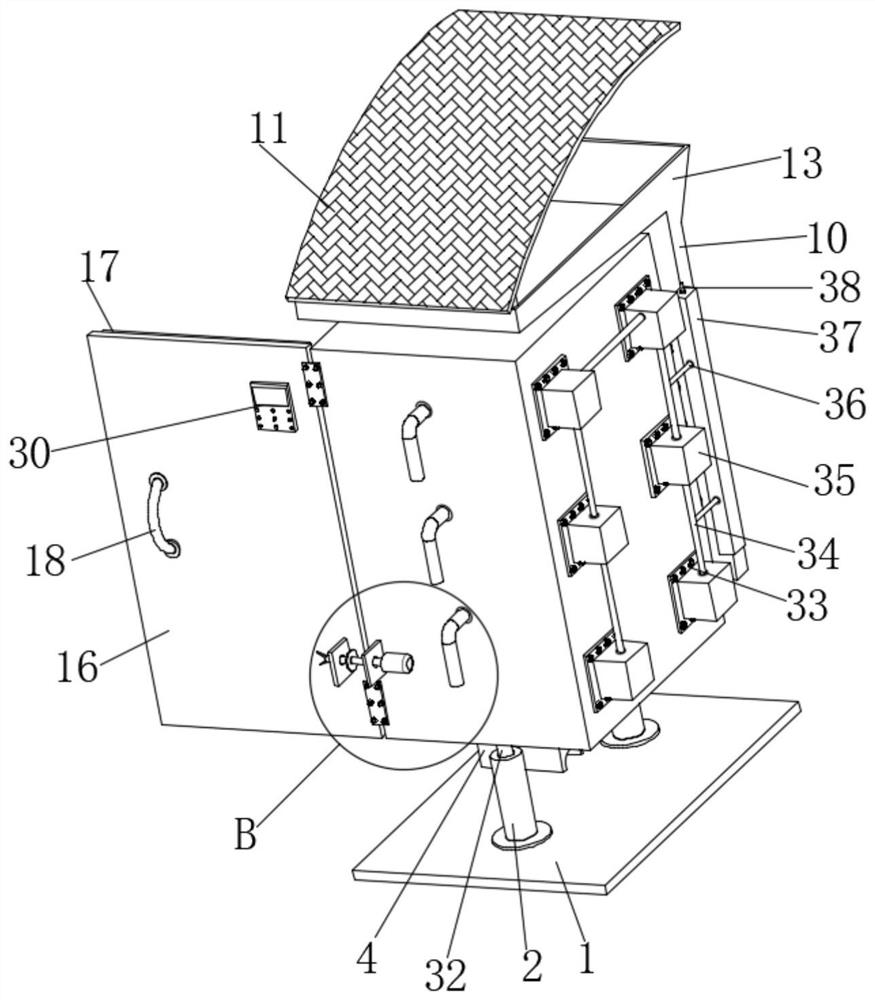

[0031] refer to Figure 1-6 , an intelligent power distribution cabinet for preventing fogging of instruments and meters, comprising a base plate 1, a cabinet body 5 and a control panel 30, one side of the cabinet body 5 is fixedly connected with a mounting plate 33, and one side of the mounting plate 33 is fixedly connected with a shell Body 35, one side of housing 35 is plugged with conduit 34, one side of conduit 34 is plugged with connecting pipe 36, one end of connecting pipe 36 is plugged with square pipe 37, and one side of square pipe 37 is plugged with equidistant Distributed suction bucket 53, one side inner wall of cabinet body 5 is provided with through groove 28, both sides inner wall of housing 35 is fixedly connected with second fixed rod 26, and one end of second fixed rod 26 is fixedly connected with motor 25, One end of the output shaft of the motor 25 is fixedly connected with a fan blade 27, and the inner wall of one side of the cabinet body 5 is fixedly co...

Embodiment 2

[0035] refer to Figure 7 , compared with Embodiment 1, this implementation also includes a spring 56 sleeved on the outer peripheral wall of the fixed column 44, and one end of the spring 56 is fixedly connected to one side of the outer wall of the limit plate 45, and the cabinet door 16 needs to be adjusted by the staff. During position-limiting work, it is necessary for the staff to twitch the fixed post 44 when opening the door and release it after the cabinet door 16 is opened. At this time, the spring 56 sleeved on the outer wall of the fixed post 44 recovers and deforms and the fixed post 44 is ejected into the positioning hole 43. Thereby finished the positioning work to cabinet door 16.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com