Novel magnetic force safety type coupler

A coupler and safety technology, applied in the field of new magnetic safety couplers, can solve the problem that the magnetic coupler cannot be used alone, affects the normal operation of the magnetic coupler, and the use conditions of the magnetic coupler are high, so as to avoid excessive immersion depth. Large, reduce the impact, avoid the effect of excessive temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

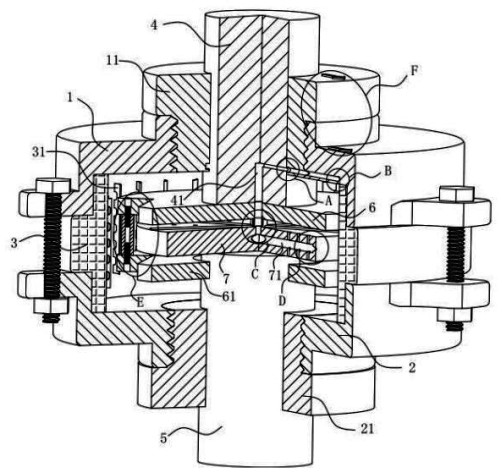

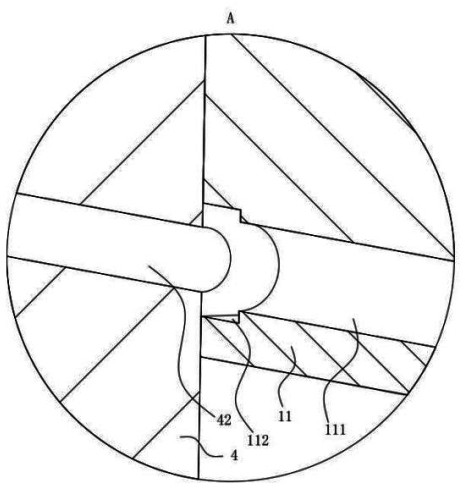

[0038] As an embodiment of the present invention, a transverse hole 71 is provided in the conductor disk 7, and the lateral hole 71 is distributed in the radial direction of the conductor disk 7; the lateral hole 71 has a plurality of, the centerline of the conductor disk 7 Uniform distribution; the lateral hole 71 is distingurated from the outlet of one end of the center of the conductor disc 7, and the diameter at the outlet is smaller than the diameter of the transverse hole 71; the conductor disk 7 is opened on the conductor disk 7; the connection hole 3 72; The centerline of the hole three 72 is coincident with the center line of the conductor disk 7, and the connection hole three 72 is turned on between the connecting hole 3 72 and the transverse hole 71; the magneto-disc 6 is fixed to the side surface of the conductor disk 7 is fixedly mounted 62 The outlet of the conduit 62 is positive to the connecting hole 3 72 on the conductor disk 7, and the end surface of the conduit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com