Gas separation and purification system and method with stable flushing regeneration effect

A technology of gas separation and purification method, which is applied in the direction of separation method, gas treatment, and dispersed particle separation, etc. It can solve the problems of lower recovery rate, failure to reach the optimal value of yield, lower overall performance of the device, etc., and achieve consistent flushing effect, Guarantee the effect of the overall operation effect and product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

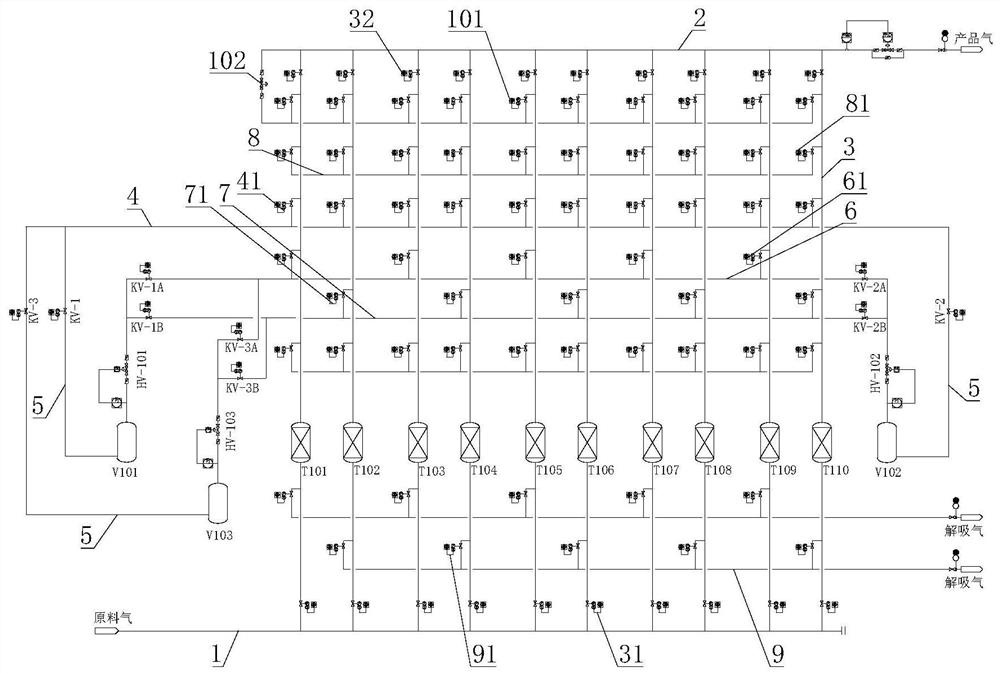

[0040] Embodiment 1: Separation and purification process of 3 parallel tanks and 10 adsorption towers

[0041] Table 2: 10-2-5 / P operation process table

[0042]

[0043] In this example, it can be seen from Table 2 of the operation process that each adsorption tower undergoes adsorption A, the first pressure drop E1D, the second pressure drop E2D, the third pressure drop E3D, and the fourth pressure drop E4D in a cycle. , the fifth pressure drop E5D, forward one PP1, forward two PP2, forward three PP3, reverse D, flushing three P3, flushing two P2, flushing one P1, fifth pressure rise E5R, fourth pressure E4R, the third pressure rise E3R, the second pressure rise E2R, the first pressure rise E1R and the final pressure rise FR, the rest of the adsorption towers also go through the same process, but the time is staggered by a sub-period.

[0044] Such as figure 1 As shown, the T101, T103, T105, T107 and T109 adsorption towers with odd numbers form a single series, and the...

Embodiment 2

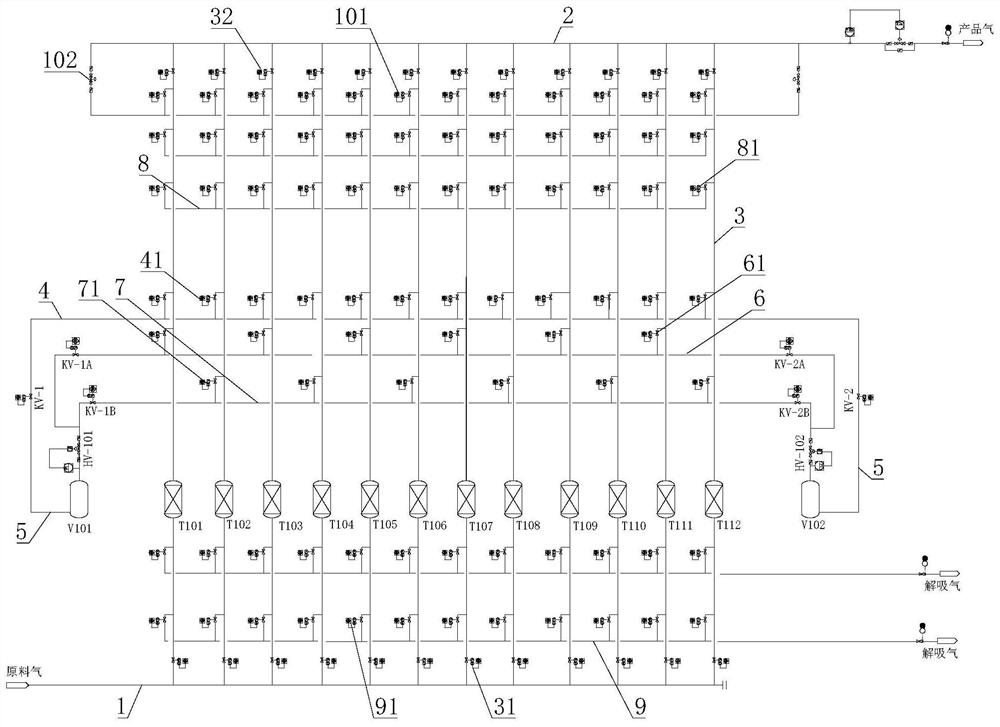

[0055] Embodiment 2: Separation and purification process of 2 parallel tanks and 12 adsorption towers

[0056] Table 3: 12-2-6 / P operation process table

[0057]

[0058] In this example, it can be seen from Table 3 of the operation process that each adsorption tower undergoes adsorption A, the first pressure drop E1D, the second pressure drop E2D, the third pressure drop E3D, and the fourth pressure drop E4D in a cycle. , the fifth pressure drop E5D, the sixth pressure drop E6D, the first PP1 forward, the second PP2 forward, the reverse D, the second flushing P2, the first flushing P1, the sixth pressure rise E6R, the fifth pressure rise E5R , the fourth pressure rise E4R, the third pressure rise E3R, the second pressure rise E2R, the first pressure rise E1R and the final pressure rise FR. cycle.

[0059] Such as figure 2 As shown, the numbered T101, T103, T105, T107, T109 and T1011 adsorption towers form a single series, and the even numbered T102, T104, T106, T108, T...

Embodiment 3

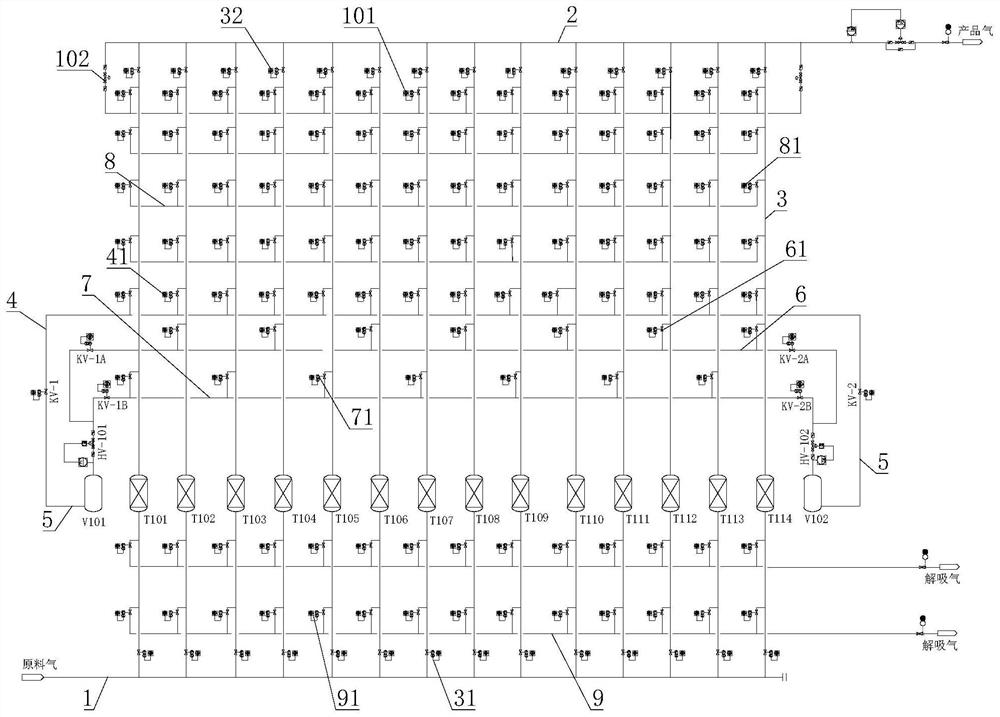

[0070] Embodiment 3: Separation and purification process of 2 parallel tanks and 14 adsorption towers

[0071] Table 4: 14-2-8 / P operation process table

[0072]

[0073]

[0074] In this example, it can be seen from Table 4 of the operating process that each adsorption tower undergoes adsorption A, the first pressure drop E1D, the second pressure drop E2D, the third pressure drop E3D, and the fourth pressure drop E4D in a cycle. , the fifth pressure drop E5D, the sixth pressure drop E6D, the seventh pressure drop E7D, the eighth pressure drop E8D, forward one PP1, forward two PP2, reverse D, flushing two P2, flushing one P1 , The eighth pressure rise E8R, the seventh pressure rise E7R, the sixth pressure rise E6R, the fifth pressure rise E5R, the fourth pressure rise E4R, the third pressure rise E3R, the second pressure rise E2R, First pressure boost E1R and final boost FR. The rest of the adsorption towers also go through the same process, but the time is staggered f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com