A connection structure of prefabricated concrete wall and its construction method

A prefabricated concrete and connection structure technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of thermal expansion and contraction, and the joints of precast concrete walls are easy to break and damage, so as to reduce the degree of mutual extrusion and prevent Secondary damage, the effect of improving the connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

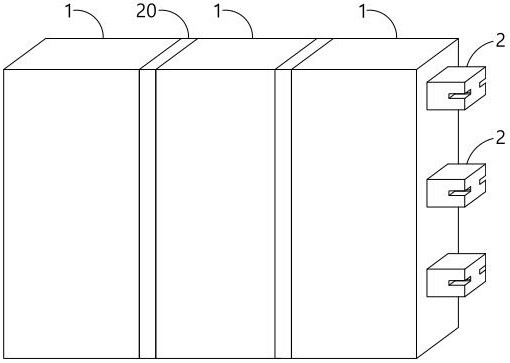

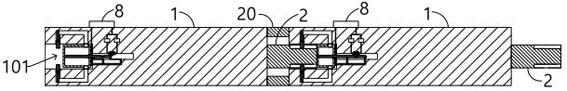

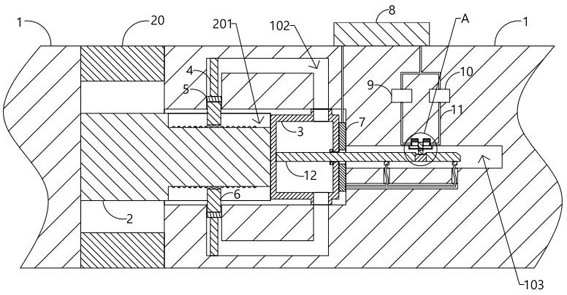

[0040] A connection structure for prefabricated concrete walls, comprising a wall 1, one end of the wall 1 is fixedly connected with several plugs 2, and the other end of the wall 1 is provided with plugs for inserting the plugs 2 of adjacent walls 1 one by one. Slot 101, insert the insert block 2 into the slot 101 of the adjacent wall body 1 to realize the connection between the adjacent wall bodies 1, and improve the connection between the adjacent wall bodies 1 through the matching connection of multiple slots 101 and the insert block 2 Strength, the end of the plug 2 away from the wall 1 is provided with a chute 201, and the slot 101 is fixed with an elastic bag 3 for storing evaporating liquid. The evaporating liquid can be water, and the plug 2 is inserted into the slot 101 and squeezed In the elastic bag 3, the evaporating liquid is heated and evaporated to form a gas, and the evaporated gas is liquefied again to form a liquid. The evaporating liquid enters the runner g...

Embodiment 2

[0051] Embodiment 2 On the basis of Embodiment 1, the connection of the wall body 1 is optimized, that is: there is a gap between adjacent wall bodies 1, and the gap is fixed and adhered by the elastic layer 20, and the elastic layer 20 is preferably made of asphalt. , by leaving a gap between adjacent walls 1, reduce the damage of thermal expansion to the junction of adjacent walls 1, and further reduce the damage of thermal expansion to the junction of adjacent walls 1 by applying elastic layer 20, and apply the elastic layer 20 also plays windproof, attractive in appearance effect.

Embodiment 3

[0053] Embodiment 3 On the basis of Embodiment 1, an elastic water-proof ring 21 is added, that is, an elastic water-proof ring 21 is fixedly connected to the inner wall of the elastic bag 3 close to the resistance groove 103, and the first resistance rod 12 slides through the elastic water-proof ring. The setting of the ring 21 and the elastic water-proof ring 21 prevent the evaporating liquid from flowing out through the connection between the first resistance rod 12 and the elastic bag 3, which will bring harm to the overall device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com