Connecting structure of precast concrete wall and construction method of connecting structure

A prefabricated concrete and connection structure technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of thermal expansion and contraction, and the joints of precast concrete walls are easy to break and damage, so as to reduce the degree of mutual extrusion and prevent Secondary damage, the effect of improving the connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

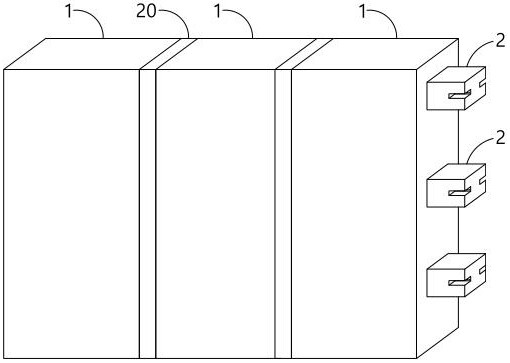

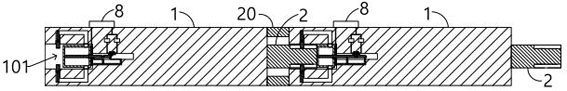

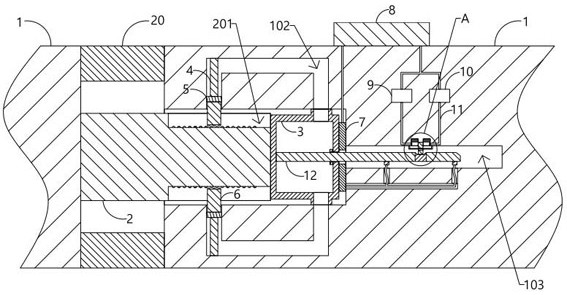

[0040] Connecting a prefabricated concrete wall structure comprising a wall, a wall at one end fixedly connected with a plurality of interpolation block 2, and 1 for the other adjacent end wall defines a wall of 2 inset eleven to inserted groove 101, the plug connector block slot 101 a wall adjacent the wall 1, 2 is inserted into the adjacent implemented, improving adjacent connecting wall connecting a plurality of through slots 101 and a mating plug block 2 strength, end of 2 inset wall 1 remote from the chute 201 defines a fixing slot 101 is provided with a storage evaporative liquid elastomeric balloon 3, alternatively evaporative liquid water, 2 interpolation block 101 extends into the slot and pressed elastomeric bladder 3, the heated evaporative liquid gas formed by evaporation, the evaporated gas formed in the liquid by the cold liquefied again, the slot 101 is connected with a channel groove 102, and the channel groove 102 and the other end in communication with the resili...

Embodiment 2

[0051] In the second embodiment on the basis of Example 1 Optimization connection wall, namely: one wall adjacent to a gap, and the gap 20 is fixed by blocking the elastic layer, the elastic layer 20 is preferably made of asphalt , by an adjacent wall of a gap, lowering the thermal expansion damage to the connection of adjacent wall, and an elastic layer 20 by applying to further reduce damage to the thermal expansion of the connection of adjacent wall, and an elastic layer applied 20 also functions as wind, aesthetic effect.

Embodiment 3

[0053] Third Embodiment increased on a basis of the embodiment of the impermeable elastic ring 21, namely: an elastic bladder tank 3 close to the inner wall of the fixed resistor 103 is connected with an elastic watertight ring 21, and the first rod 12 slides through the elastic resistance riser ring 21, the elastic ring 21 disposed impermeable to prevent evaporation of fluid bladder 12 and the elastic rod 3 through the first resistor is connected at the outflow, harm to the entire device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com