T-shaped connecting piece and H-shaped steel beam combined frame structure joint construction method

A frame structure and construction method technology, applied in the direction of building types, building components, building structures, etc., can solve the problems of poor ductility of beam-column joints, easy brittle failure, low energy consumption, etc., to ensure joint strength and improve absorption The effect of anti-seismic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

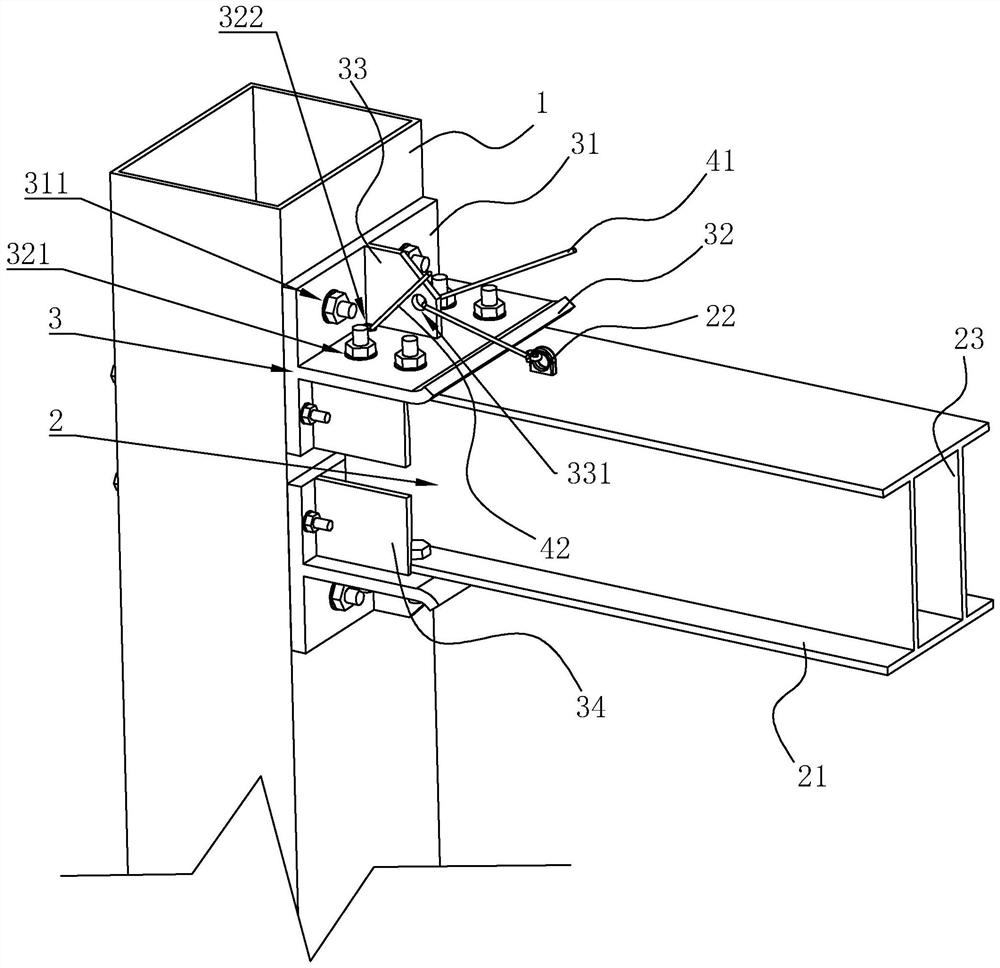

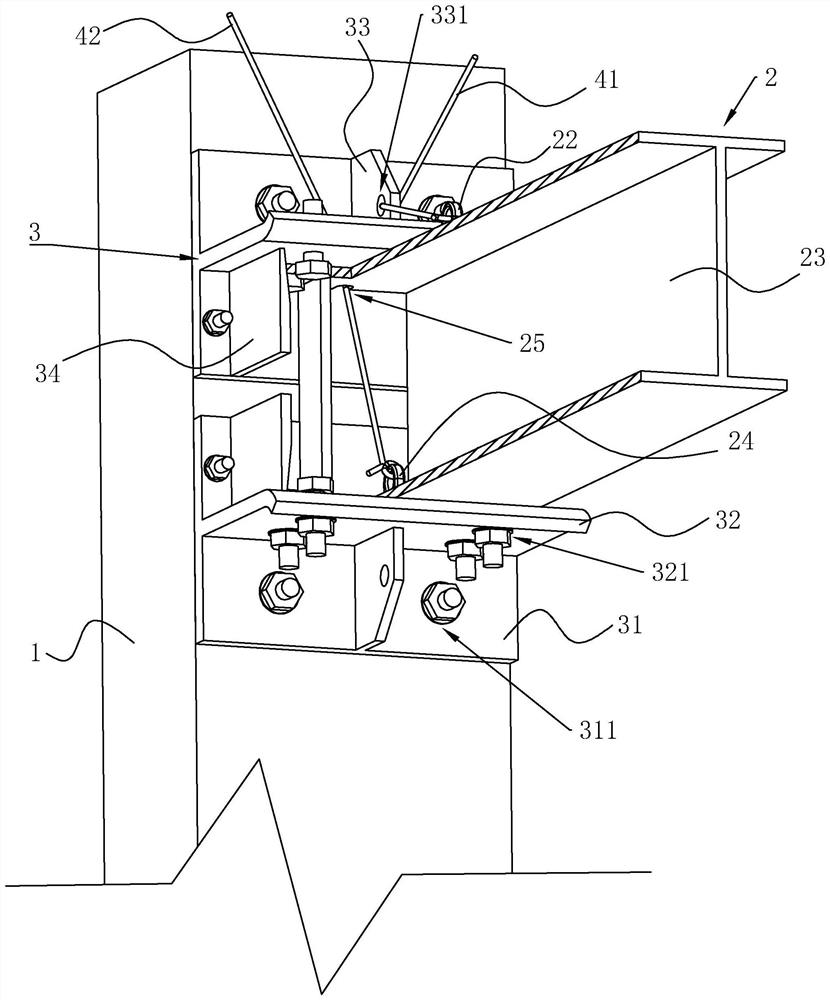

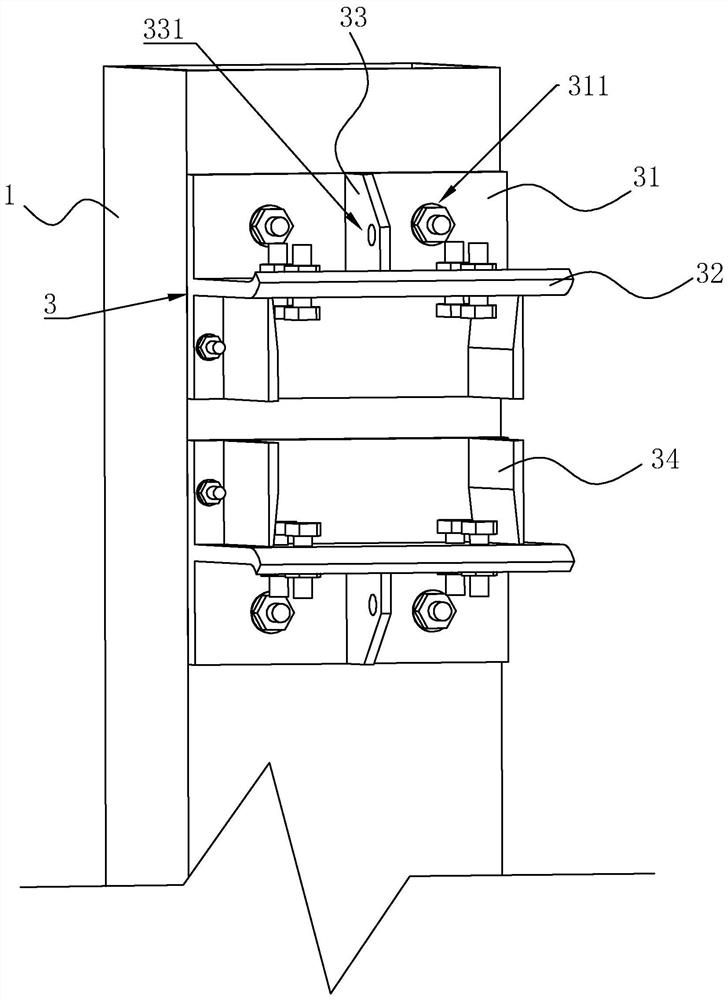

[0036] Contraction below Figure 1-3 Further detailed description of the present application.

[0037] like Figure 1 to 2 As shown, the present application discloses a T-type connector and an H-type steel beam combination frame structure node construction method, including the following steps:

[0038] Step 1: Prefabricated T-type connector 3 and the H-type steel beam 2, and the steel column 1 are pretreated;

[0039] The T-type connector 3 includes a vertically disposed mounting plate 31 and a horizontal arranged connection plate 32, and the connecting plate 32 is fixed to the middle of the mounting plate 31, and the mounting plate 31 is opened through a plurality of second mounting holes 311, the connecting plate 32 Throughout there are several second connecting holes 321. The T-type connector 3 also includes a first reinforcing plate 33 and a second reinforcing plate 34 respectively fixed to the connecting plate 32, and the first reinforcing plate 33, the second reinforcing plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com