Automobile fuel pump with improved NVH performance

A fuel pump and automobile technology, which is applied to liquid fuel feeders, charging systems, machines/engines, etc., can solve problems such as adverse effects on interior noise quality, turbulence, and fuel pump vibration, and improve interior noise. Experience the effect of comfort, simple structure design, and improved noise quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

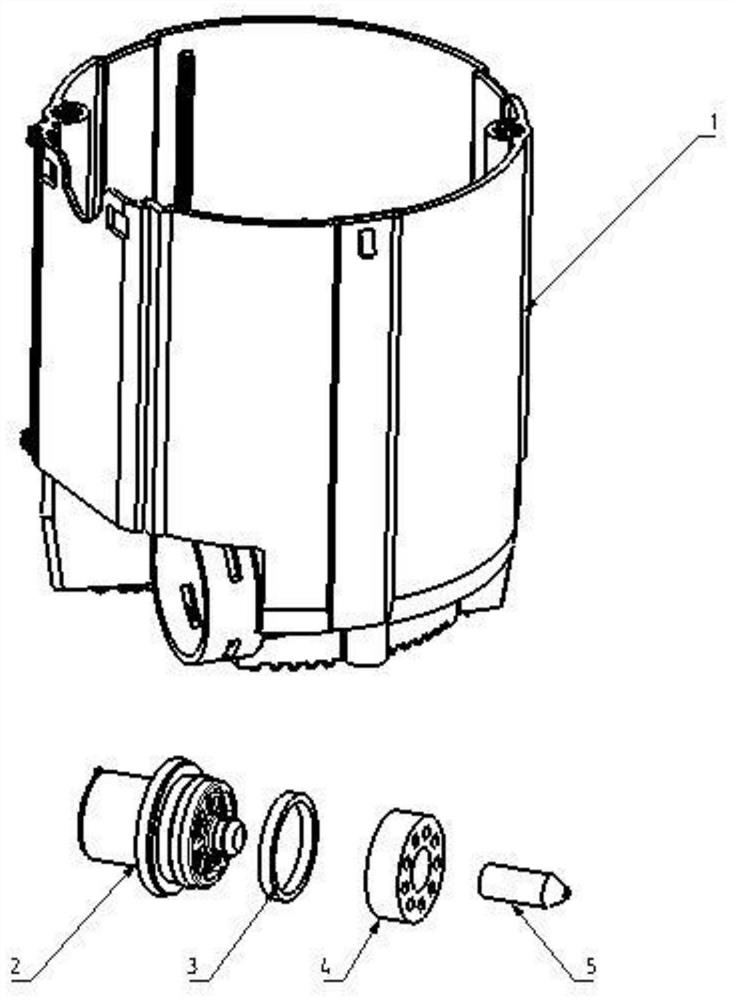

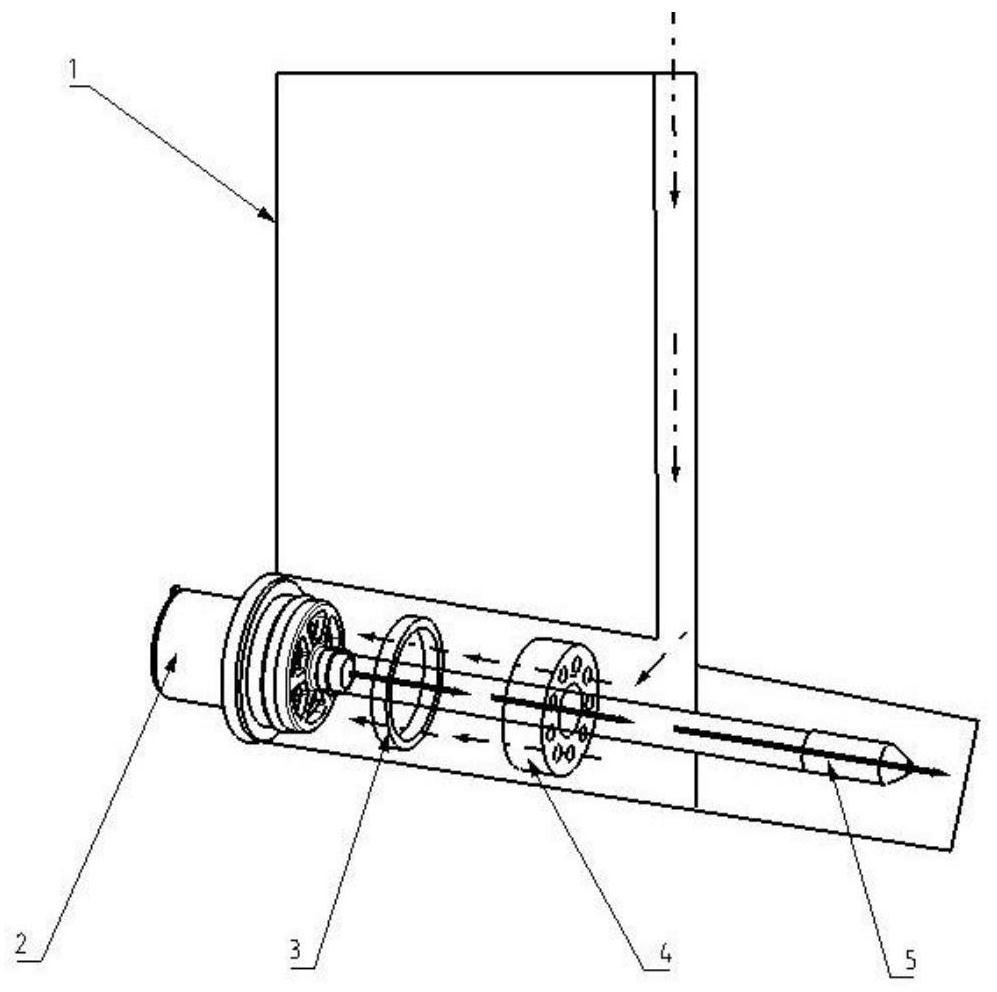

[0042] Such as figure 1 As shown, the block 3 and the damper 4 are placed in front of the inlet of the pressure regulating valve 2. If the layout space is limited, the block 3 may not be added. The fuel pumped by the fuel pump motor passes through the oil return channel of the oil storage tank 1, First, rectify through the damper 4, then enter the interior of the pressure regulating valve 2 from the inlet, then flow out from the outlet of the pressure regulating valve 2, and finally flow into the interior of the oil storage barrel 1 through the ejector pump 5.

Embodiment 2

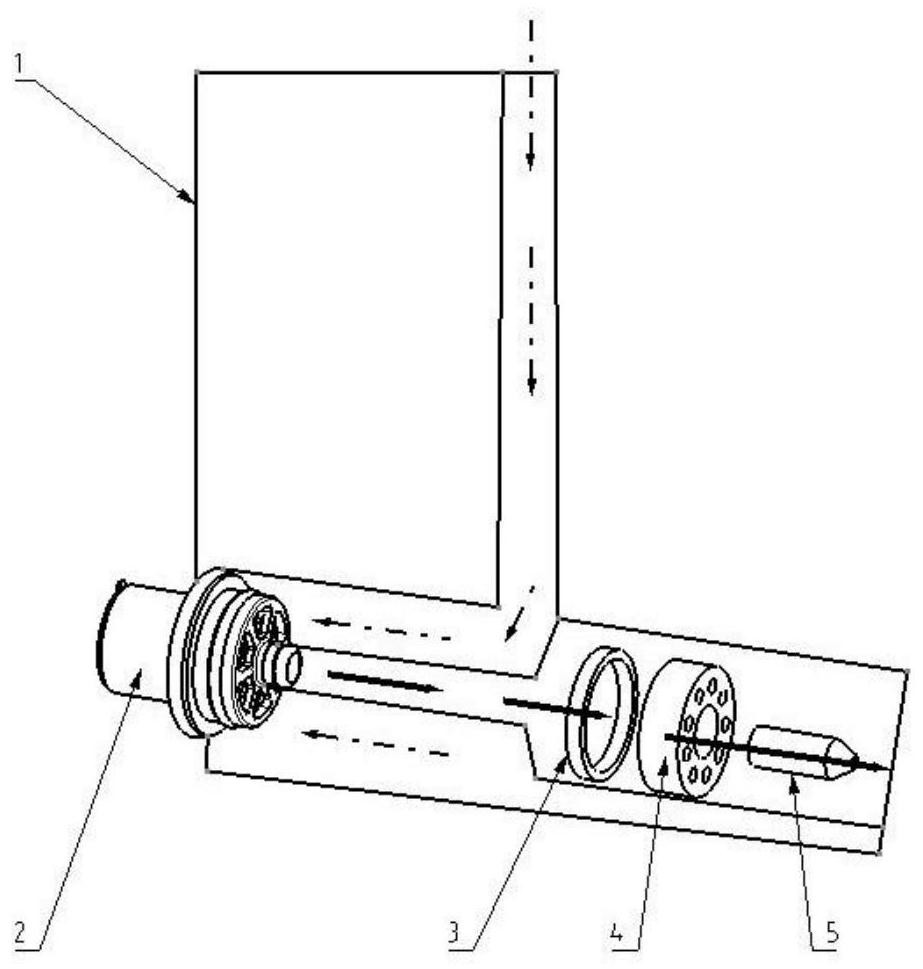

[0044] As shown in Figure 2, the stopper 3 and the damper 4 are placed behind the outlet of the pressure regulating valve 2. If the layout space is limited, the stopper 3 may not be added. The oil flow channel first enters the interior of the pressure regulating valve 2, then flows out from the outlet of the pressure regulating valve 2, then enters the ejector pump 5 through the damper 4, and finally flows into the oil storage barrel 1. Both of the above two methods make the turbulent flow state of the return oil rectified and improved after flowing through the damper 4, which optimizes the fuel pump vibration and fluid disturbance state to a large extent, and the NVH performance of the fuel pump is significantly improved. Reduce the noise of the fuel pump in the field, improve the noise quality of the fuel pump in the car, and improve the noise experience comfort of the driver and passengers in the car.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com