Dried flower preparation process

A preparation process and technology of dried flowers, applied in drying, drying machines, decorative arts, etc., can solve the problems of incomplete dried flowers, affecting the quality of dried flowers, and high water content in roots, so as to achieve good quality of finished products, improve drying uniformity, The effect of high drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

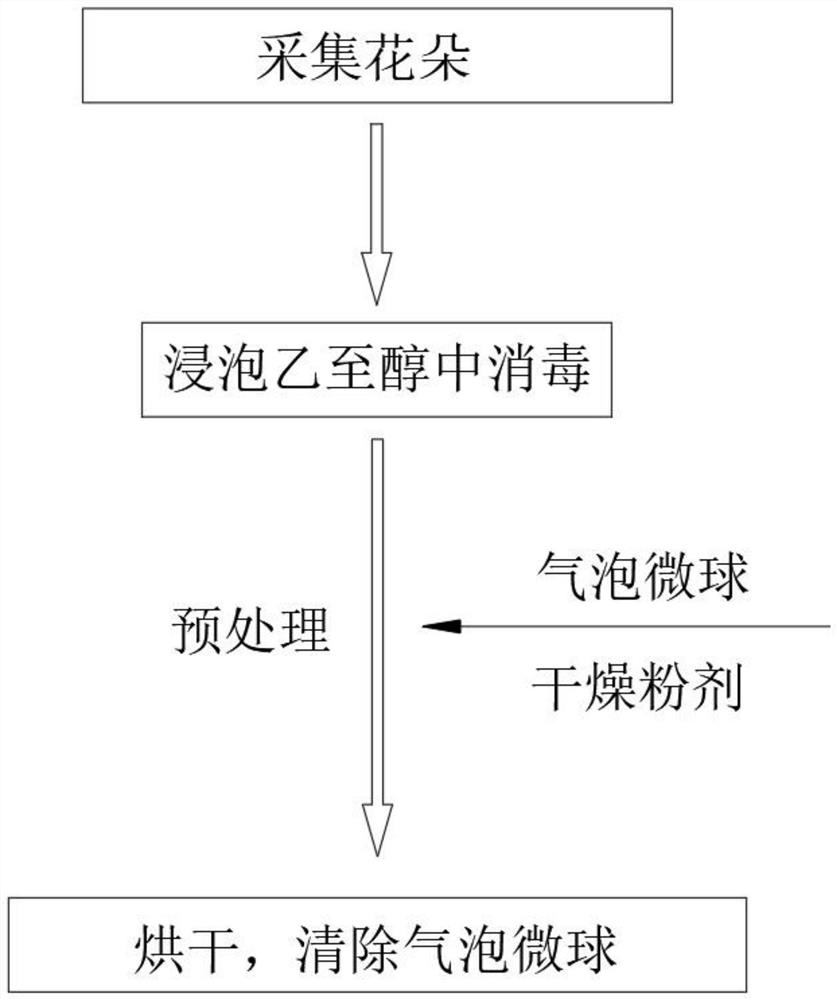

[0046] see figure 1 , a dry flower preparation process, comprising the following steps:

[0047] S1. First collect fresh flowers, which are preferably semi-open or fully open, then trim, remove branches and leaves, and use running water to clean to remove floating ash;

[0048] S2. Soak the pruned flowers in an ethanol solution, let stand for 0.5-1h, and then pick them up to obtain sterilized and antibacterial flowers;

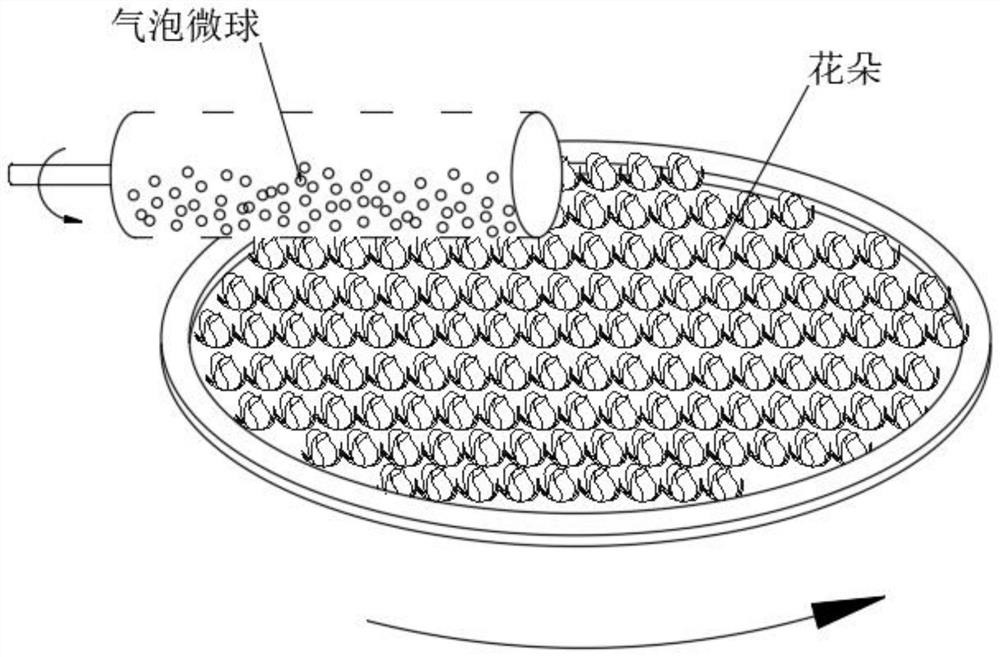

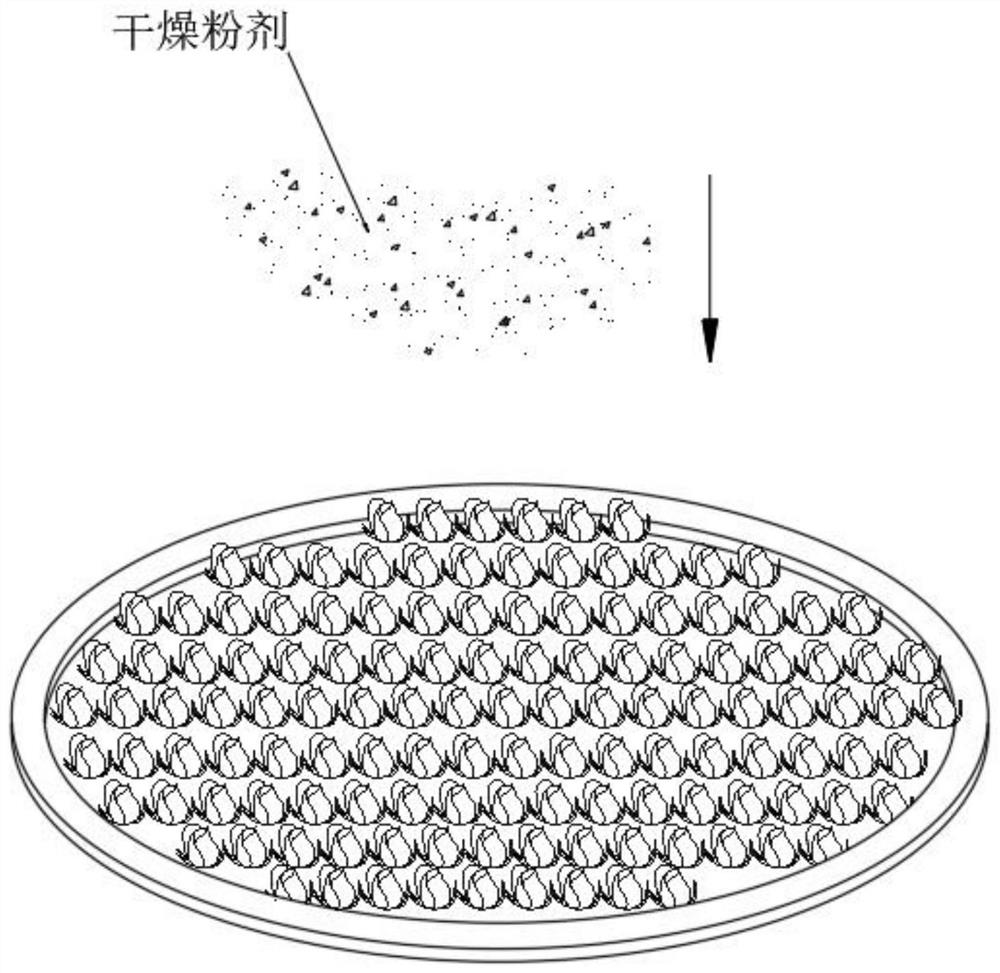

[0049] S3, carry out pretreatment to flower, as Figure 4 , so that the inside of the petal void is mixed with bubble microspheres;

[0050] S4. Then lay the pretreated flowers on the sieve, dry them, invert them, and brush them with a brush to remove the internal air bubbles and microspheres to obtain dried flowers.

[0051] The concentration of the ethanol solution is 55-75%, and the temperature during drying is 70-90°C. In step S3, pretreatment is carried out when the ethanol on the flowers is not completely drained and volatilized. At this time, during...

Embodiment 2

[0060] see Figure 8-9 , the bubble microspheres include a transparent shell 5 and an inner liquid bag 6 fixedly connected in the transparent shell 5, the inner liquid bag 6 is filled with a mixture of water and alcohol, and the transparent shell 5 is also filled with overflow gas Filling, the outer end of the inner liquid bag 6 is fixedly connected with a spider-shaped conduit 7 communicating with it, and the outer end of the spider-shaped conduit 7 is fixedly connected with a plurality of pneumatic strips 8 toward the center of the transparent casing 5, and the other end of the spider-shaped conduit 7 is fixed Connected with a plurality of evenly distributed overflow rods 9, the pneumatic strip 8 is a flexible hollow porous strip structure, the overflow rod 9 is a hard porous rod-shaped structure, and both the pneumatic strip 8 and the overflow rod 9 communicate with the spider-shaped conduit 7, And both of them are fixedly connected with an elastic film at the mouth of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com