Multi-axis tensile testing machine and testing method

A technology of tensile testing and testing methods, applied in the direction of applying stable tension/compression to test the strength of materials, measuring devices, instruments, etc., which can solve problems such as slow speed, poor stability, and complicated installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the objects, technical solutions and advantages of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and examples. It will be appreciated that the specific embodiments described herein are intended to explain the invention and is not intended to limit the invention. Further, the technical features according to each of the various embodiments described below can be combined with each other as long as they do not constitute a collision between each other.

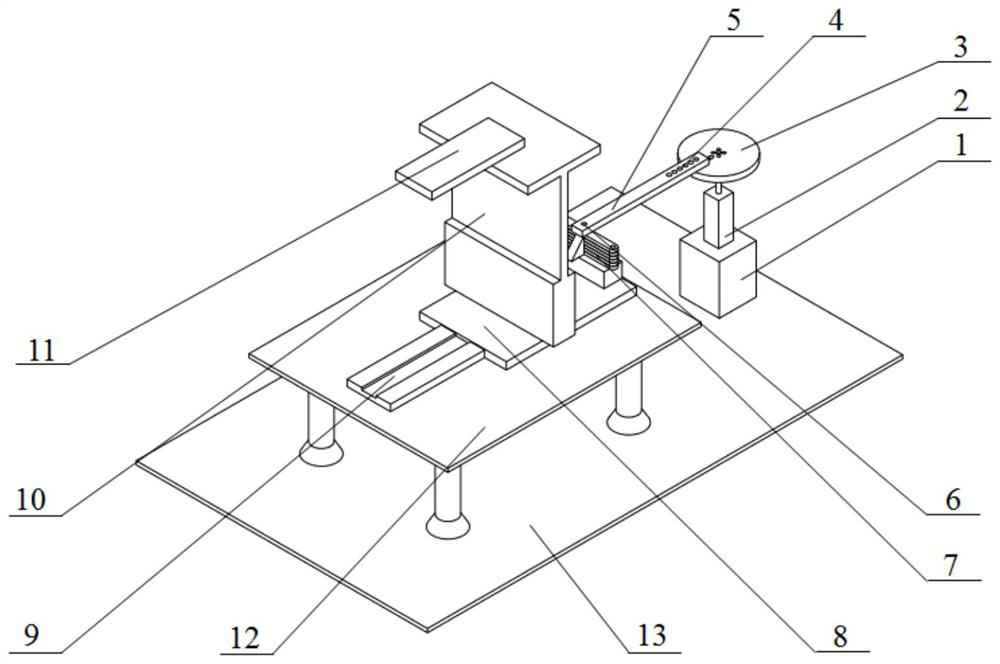

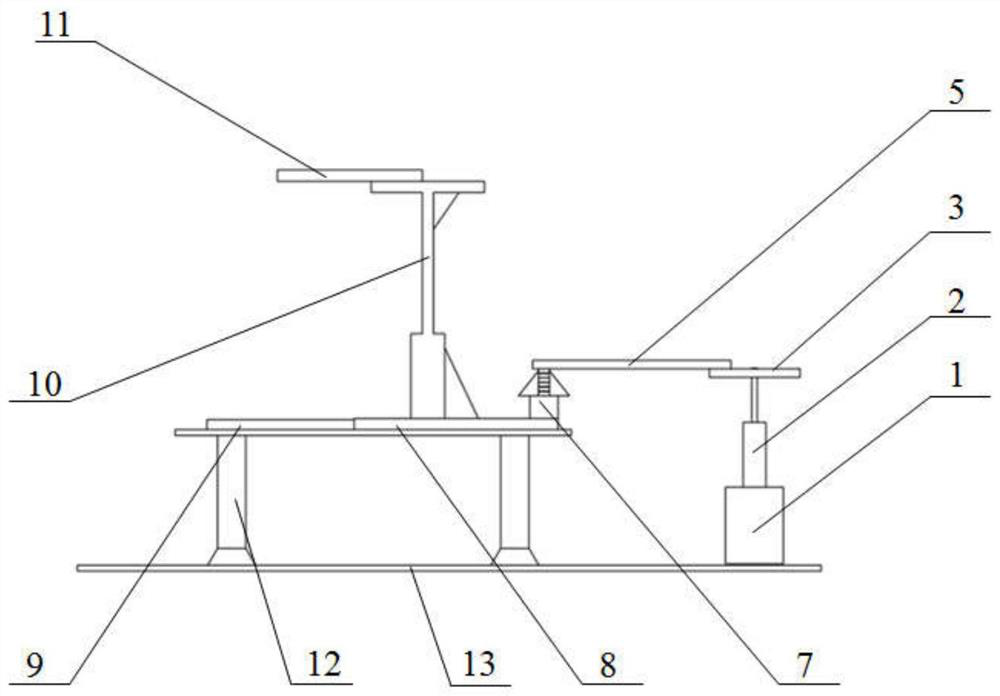

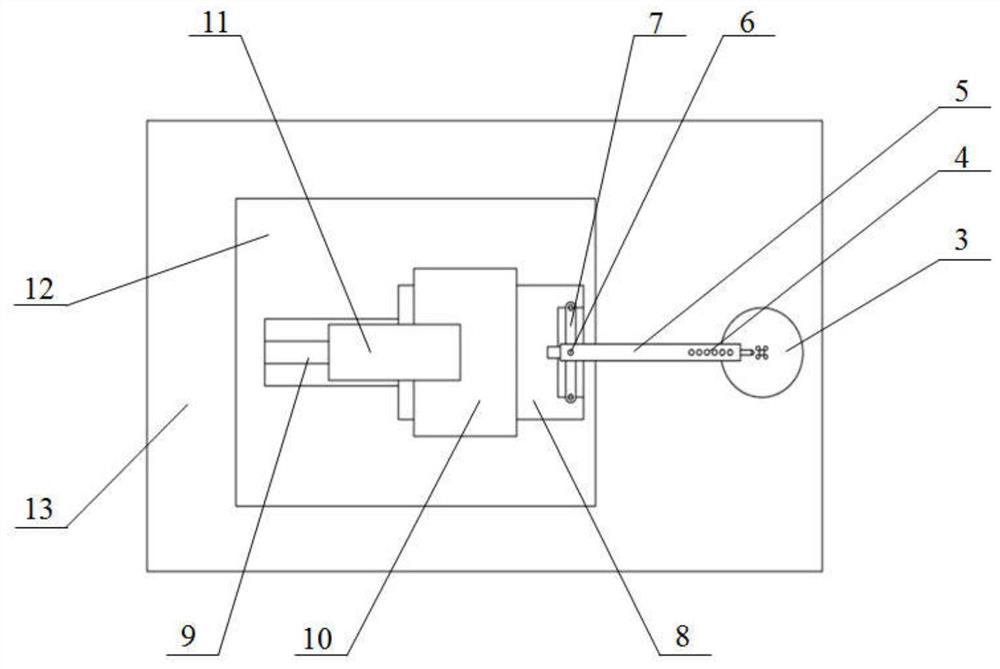

[0033] The present invention provides a multi-axis tensile testing machine testing, uniaxial stretching by a number of fixing means on the base configuration. Figure 1-3 Given at different perspective schematic structural diagram of a single uniaxial stretching apparatus.

[0034] Said apparatus comprises a uniaxial stretching machine 1, the coupling 2, the turntable 3, a first fastening screw 4, link 5, the second fastening s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com