Method for conveniently detecting dispersity of cobalt salt in sizing material

A technology of dispersibility and sizing material, which is applied in the field of convenient detection of cobalt salt dispersibility in sizing materials, can solve the problems of large fluctuation of test results, low reference and high cost of precision instruments, and saves experiment cost, time, and accurate results. High-quality, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The method provided in this specific example to facilitate the detection of the dispersion of cobalt salt in the rubber will directly reflect the adhesion between the steel cord and the rubber according to the dispersion of the cobalt salt. The better the dispersion, the better the adhesion effect The mechanism of the method is to detect the adhesion between the steel cord and the rubber by directly peeling the steel cord from the surface of the rubber, and then reflect the dispersion of cobalt salt in the rubber.

[0036] Specifically, the method for facilitating the detection of cobalt salt dispersibility in the sizing material provided by this specific embodiment specifically includes the following steps:

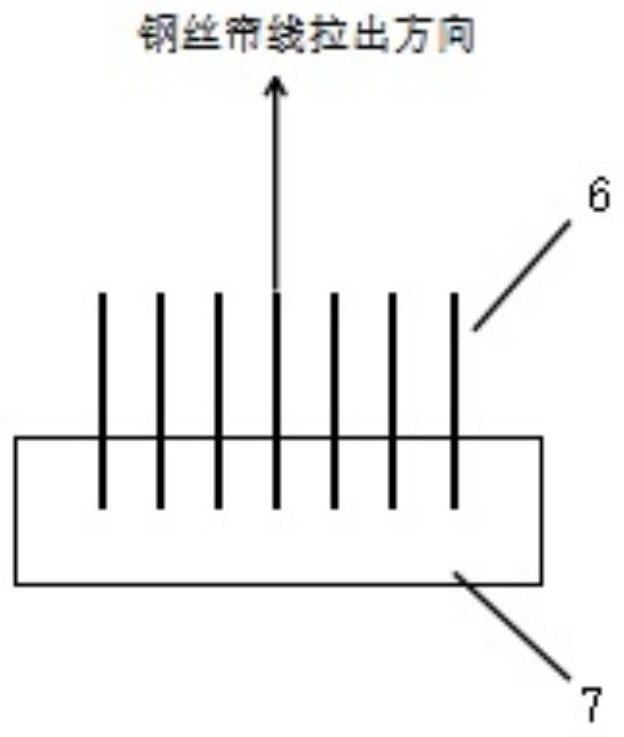

[0037] (1) Grind the sample to be tested until the steel cord is looming on the surface of the rubber compound. Generally, the distance between the steel cord and the surface of the rubber compound is 0.05-0.5 mm, preferably 0.1 mm.

[0038] (2) Peel off the steel...

Embodiment 2

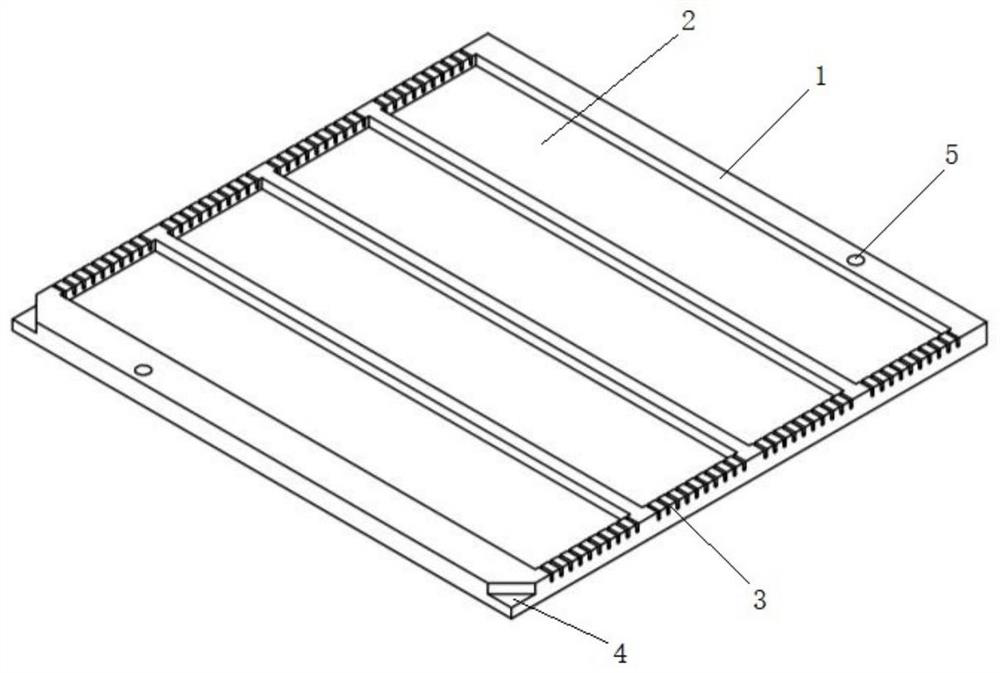

[0042] In this specific example, if image 3As shown, in order to make the sample to be tested better meet the requirements of the rubber and steel cord adhesion testing experiment, a sample making mold is specially made, and the sample making mold includes a mold plate 1, a cover plate and a positioning piece , the mold plate 1 is provided with a plurality of sample preparation grooves 2, and the mold plate 1 on the opposite sides of the sample preparation groove 2 is provided with a plurality of steel wire grooves 3, and the two opposite sides of the sample preparation groove 2 are located A plurality of steel wire grooves 3 are arranged in one-to-one correspondence and opposite to each other. The steel wire grooves 3 communicate with the outer end of the sample preparation groove 2 and the mold plate 1. This setting facilitates the insertion of steel wire cords. The cover plate is detachable through the positioning piece. It is connected to the side of the mold plate 1 prov...

Embodiment 3

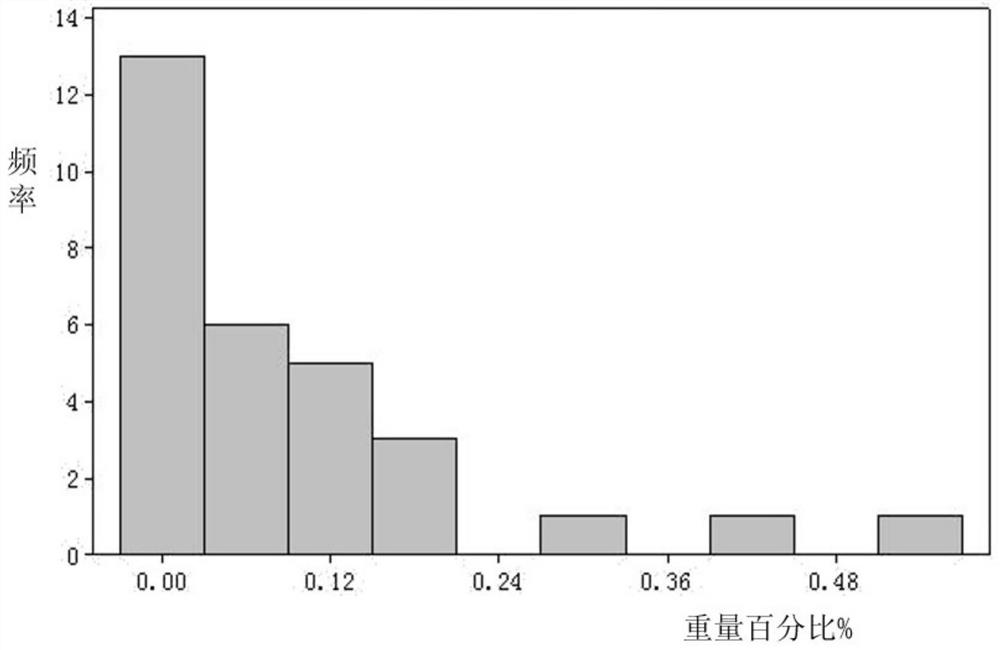

[0056] Verification test of cobalt salt dispersion detection method in the sizing material of embodiment 3

[0057] Cobalt ions play the role of bonding in the rubber. Because of the high price and toxicity of cobalt, the content of cobalt in the rubber is generally very small, usually only accounting for about 0.3% of the total weight of the formula. However, if cobalt is in the rubber If the content is too small, the adhesive force of the rubber compound will be poor.

[0058] In this specific example, the cobalt salt dispersion detection method provided in Example 2 is used to detect two kinds of rubber materials with different cobalt contents, and to verify the feasibility of the cobalt salt dispersion detection method in the rubber materials. Specifically, two different cobalt content The specific components of the sizing material in parts by weight are as shown in Table 1, and the cobalt salt dispersion detection method provided in Example 2 is used to detect the two kin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com