Industrial digital twinning virtual and real data fusion method, system, device and terminal

A data fusion, virtual and real technology, applied in special data processing applications, unstructured text data retrieval, semantic tool creation, etc., to achieve the effect of close connection, solving multi-source heterogeneity and semantic heterogeneity, and diverse structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

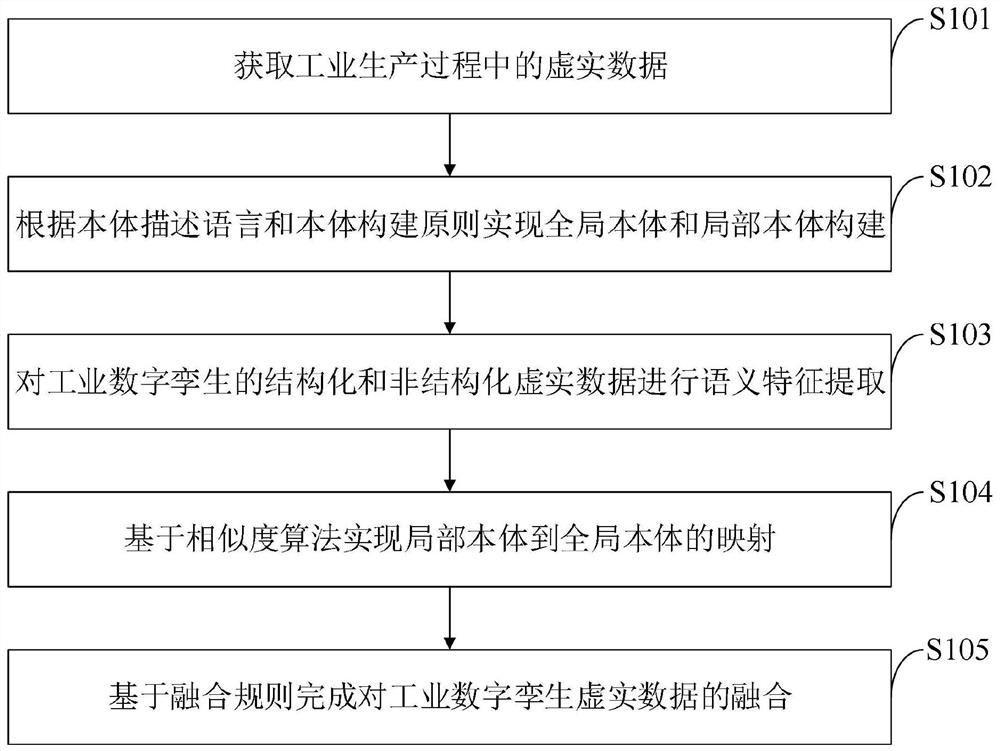

[0108] Aiming at the problems described in the background technology, the present invention proposes an ontology-based industrial digital twin virtual-real data fusion method, adopting the following technical solutions:

[0109] (1) Obtain virtual and real data in the process of industrial production.

[0110] (2) According to the ontology description language and ontology construction principles, a set of ontology construction methods for the industrial field is proposed; and the construction of global ontology and local ontology is realized. Its construction process is as follows Figure 4 shown.

[0111] (2.1) Determining the application field and scope of ontology: the scope of application of the clearly constructed ontology is the industrial field.

[0112] (2.2) Data collection and analysis: Through the collected industrial virtual and real data, introduce the conceptual terminology of the industrial domain database to clarify the virtual and real data, so as to ensure...

Embodiment 2

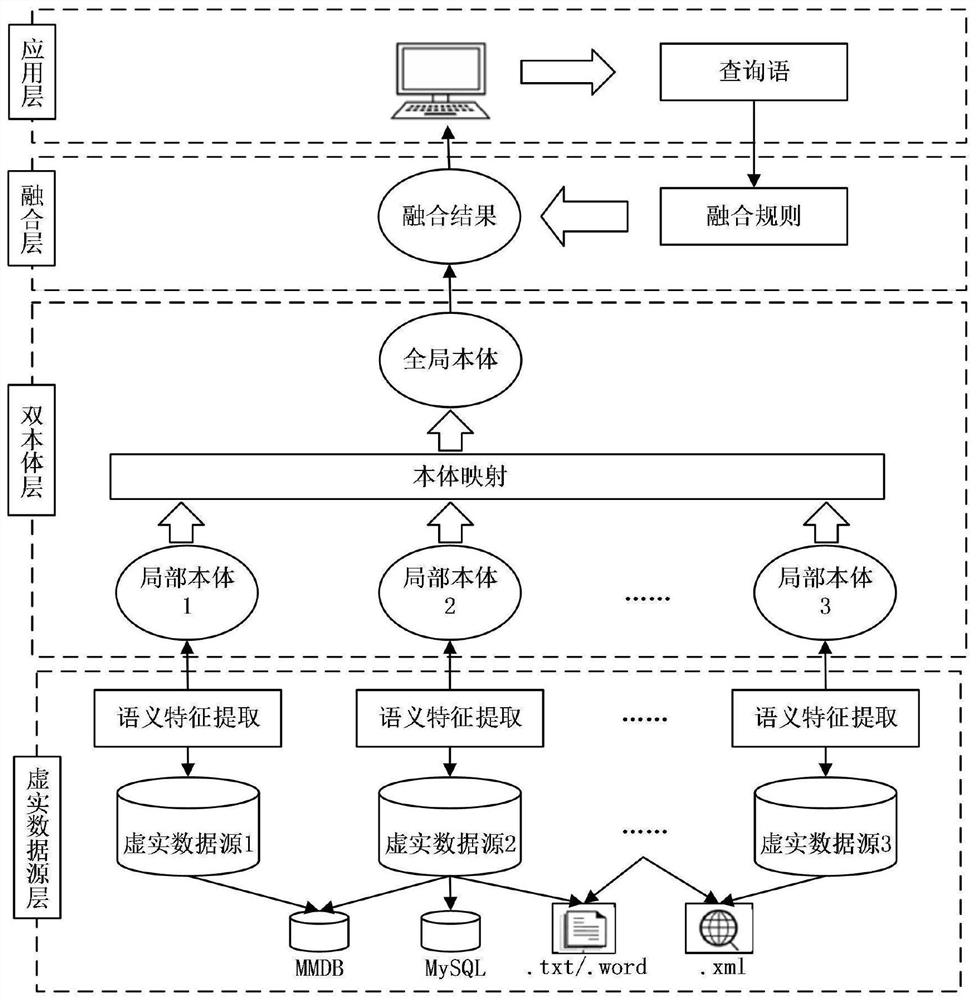

[0171] refer to figure 2 , the specific implementation steps of the present invention are as follows:

[0172] Step 1: Obtain the virtual and real data of the digital twin of the casting process of the fan hub.

[0173] Step 2: According to ontology construction method and WOL+RDFS standard ontology modeling language, construct global ontology and local ontology of fan hub casting process:

[0174] (2.1) Use the ontology modeling language to describe the relationship between some concepts and attributes in the global ontology of the wheel hub casting process. The partial ontology description language of the global ontology of the wheel hub casting process is shown in Table 2.

[0175] Table 2 OWL+RDFS Ontology Description Results

[0176]

[0177]

[0178] According to the ontology construction method and the industrial manufacturing domain database, the knowledge in the wheel hub casting process is extracted and established from the concept entities, concept attribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com