Optical fiber winding defect detection method and device based on ensemble learning

A defect detection and integrated learning technology, applied in image data processing, instrument, character and pattern recognition, etc., can solve problems such as misjudgment and missed detection, environmental interference and misdetection, difficult to locate accurately, etc. Environmental interference, high adaptability, and the effect of reducing frequent machine downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

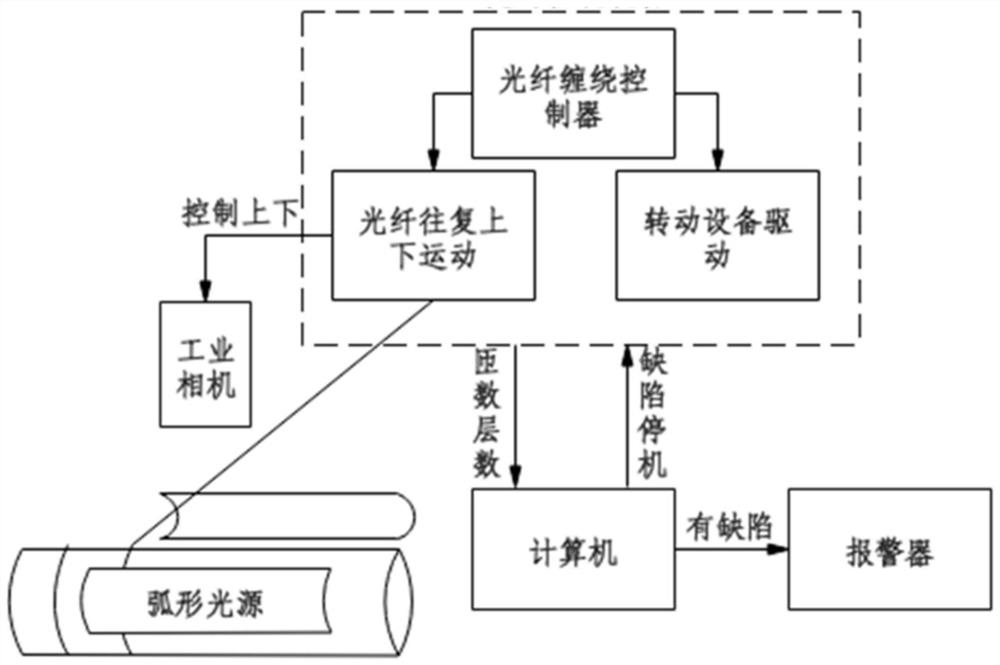

[0050] The invention provides a method and system for detecting defects in optical fiber winding.

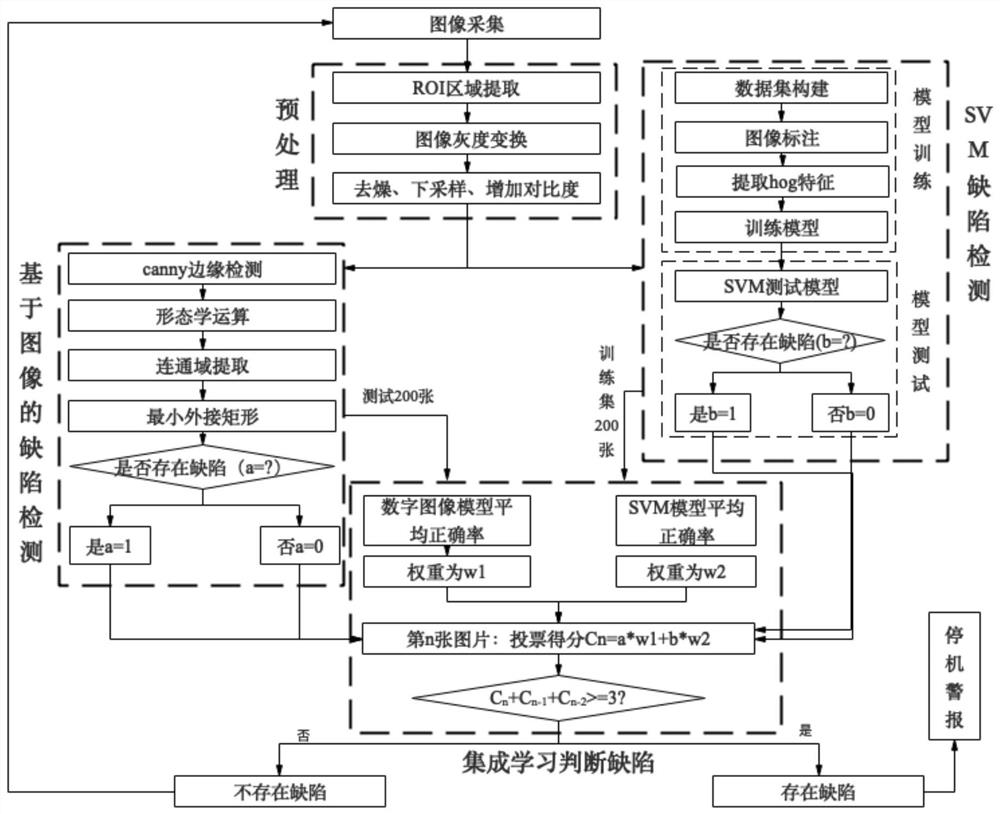

[0051] In some embodiments, a fully automatic optical fiber winding defect detection method includes a digital image processing algorithm part and an SVM learning algorithm part:

[0052] The first step: image collection, collecting industrial data images, intercepting the ROI (region of interest) area that has just been wrapped, and inputting it into the image preprocessing system.

[0053] The second step: image preprocessing. Perform preprocessing such as grayscale conversion, noise removal, image downsampling, and contrast increase on the collected images to lay the foundation for subsequent detection.

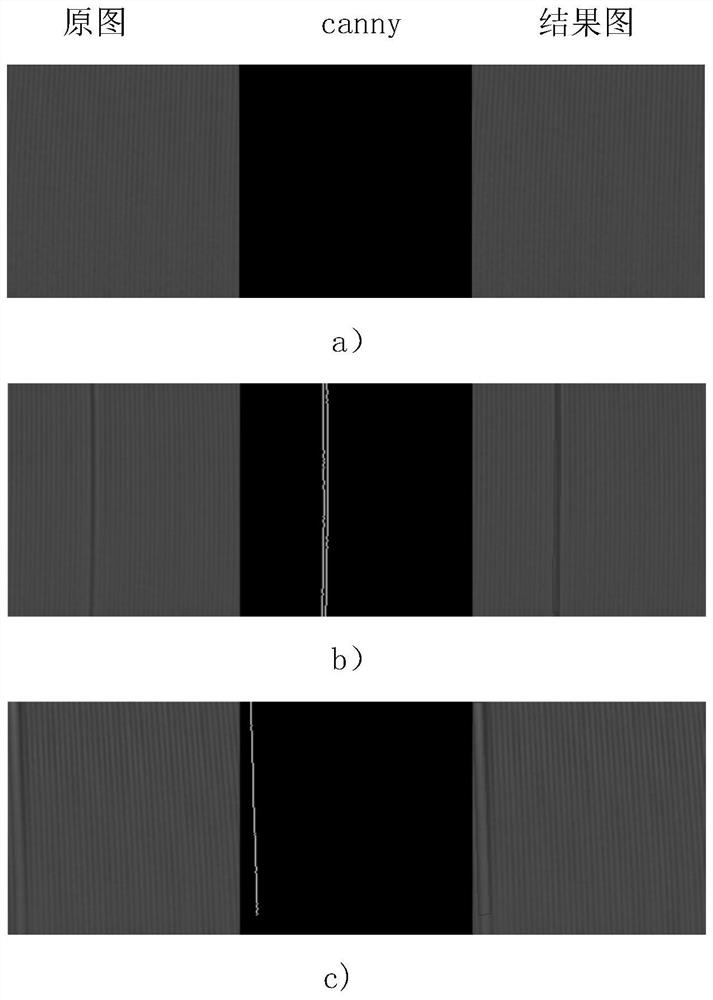

[0054] Step 3: Digital image processing to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com