Preparation method of dual emulsion and application of dual emulsion to astaxanthin carrying

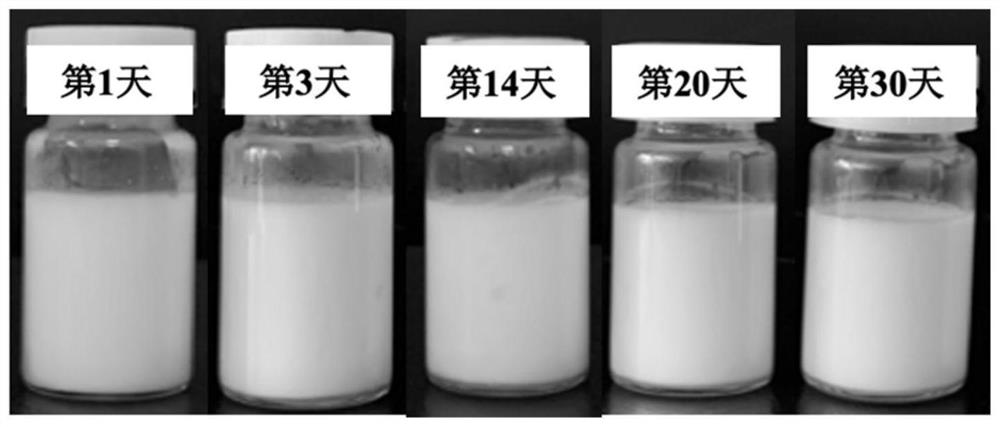

A double emulsion, emulsion technology, applied in the application, food ingredients as emulsifier, oil-containing food ingredients, etc., can solve the problem of limited application of astaxanthin, and achieve the effect of improving emulsion stability, expanding application and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

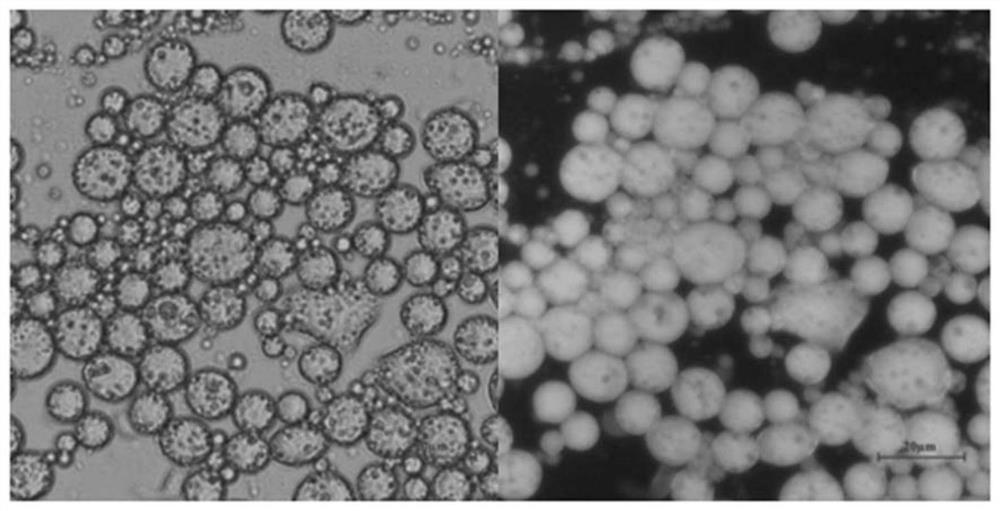

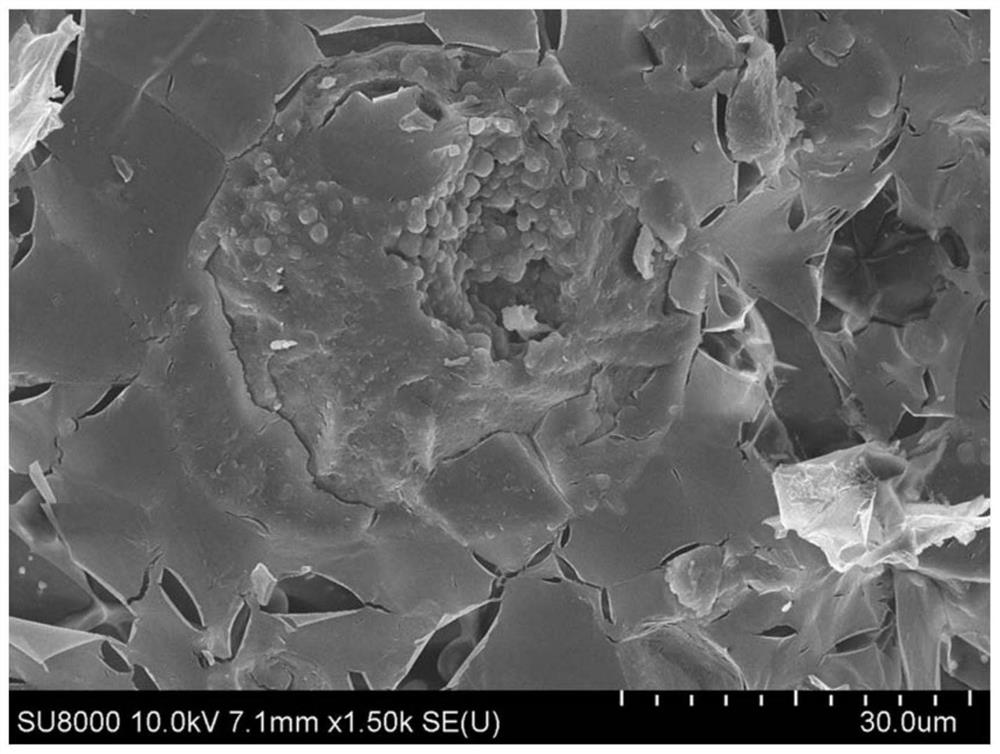

[0043] A kind of preparation method of double emulsion, concrete steps are as follows:

[0044] 1. Dissolve 0.8g of gelatin in 10mL of deionized water, soak for 45 minutes, stir and dissolve in a water bath at 70°C as the inner water phase W 1 , and set aside after cooling. At 60° C., 4% (w / v) polyglycerol ricinoleate and 10 mL of soybean oil were mixed and stirred for 20 min, and oil phase O was obtained after the polyglycerol ricinoleate was completely dissolved. Water Phase W 1 The oil phase O is sheared according to the volume ratio of 1:4, and the shearing condition is 15000r / min, 7min. After shearing, the primary emulsion W 1 / O.

[0045] 2. Add 1.5g of sodium caseinate into 50mL of deionized water, and stir for 12 hours to form a solution as the external water phase W 2 .

[0046] 3. Take 1mL of the primary emulsion and slowly add 2.4mL of the external water phase W at a shear rate of 13000r / min 2 , that is, shearing for 7 minutes according to the volume ratio of...

Embodiment 2

[0050] A kind of preparation method of double emulsion, concrete steps are as follows:

[0051] 1. Dissolve 1g of gelatin in 10mL of deionized water, soak for 45min, stir and dissolve in a water bath at 70°C as the inner water phase W 1 , and set aside after cooling. At 55° C., 5% (w / v) polyglycerol ricinoleate and 10 mL of soybean oil were mixed and stirred for 30 min, and oil phase O was obtained after the surfactant was completely dissolved. Water Phase W 1 The oil phase O was sheared according to the volume ratio of 1:4, and the shearing condition was 14000r / min, 7min. After shearing, the primary emulsion W 1 / O.

[0052] 2. Add 1.5g of sodium caseinate into 50mL of deionized water, and stir for 12 hours to form a solution as the external water phase W 2 .

[0053] 3. Take 2mL of the primary emulsion and slowly add 3mL of the external water phase W at a shear rate of 10000r / min 2 , that is, shearing for 10 minutes according to the volume ratio of 2:3 to obtain a sta...

Embodiment 3

[0057] A kind of preparation method of double emulsion, concrete steps are as follows:

[0058] 1. Dissolve 1g of gelatin in 10mL of deionized water, soak for 45min, stir and dissolve in a water bath at 70°C as the inner water phase W 1 , and set aside after cooling. At 60° C., 4% (w / v) polyglycerol ricinoleate and 10 mL of soybean oil were mixed and stirred for 20 min, and oil phase O was obtained after the polyglycerol ricinoleate was completely dissolved. Water Phase W 1 The oil phase O is sheared according to the volume ratio of 1:4, and the shearing condition is 13000r / min, 7min. sheared to primary emulsion W 1 / o.

[0059] 2. Add 1.5g of sodium caseinate into 50mL of deionized water, and stir for 12 hours to form a solution as the external water phase W 2 .

[0060] 3. Take 4mL of the primary emulsion and slowly add 6mL of the external water phase W at a shear rate of 13000r / min 2 , that is, shearing for 10 minutes according to the volume ratio of 2:3 to obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com