Device and method for improving quality of organosilicon hydrolysate

A hydrolyzate, organosilicon technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve problems affecting the quality of hydrolyzates, and achieve the effects of reliable performance, improved quality, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

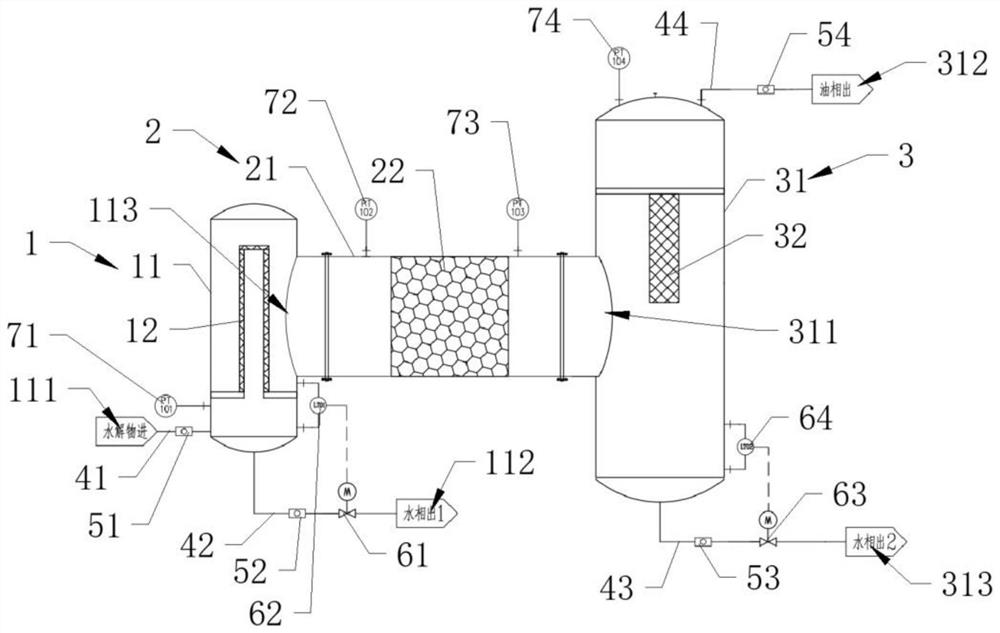

[0046] Reference manual attached figure 1 , the device provided by the present invention for improving the quality of organosilicon hydrolyzate is described, which can effectively reduce the moisture and chloride ion content in organosilicon hydrolyzate, and can effectively increase the light transmittance of the hydrolyzate, improve The quality of the hydrolyzate.

[0047] Reference manual attached figure 1 , specifically, the device for improving the quality of organosilicon hydrolyzate includes a solid-liquid separation mechanism 1 , an oil-water separation mechanism 2 and an emulsion purification mechanism 3 . The solid-liquid separation mechanism 1 includes a first cavity 11 and a solid-liquid separation filter element 12 installed in the first cavity 11 . The oil-water separation mechanism 2 includes a second cavity 21 and an oil-water separation packing 22 installed in the second cavity 21 . The emulsion purification mechanism 3 includes a third cavity 31 and an emulsi...

Embodiment 2

[0068] According to another aspect of the present invention, the present invention further provides a method for improving the quality of organosilicon hydrolyzate, comprising:

[0069] S101: Guide the hydrolyzate through the solid-liquid separation filter element 12 of the solid-liquid separation mechanism 1 to filter the solid impurities in the hydrolyzate and discharge it through the first water phase outlet 112;

[0070] S102: Guide the hydrolyzate after filtering solid impurities to pass through the oil-water separation filler 22 of the oil-water separation mechanism 2 to remove water and chloride ions;

[0071] S103: guide the hydrolyzate after removal of water and chloride ions to pass through the emulsion purification membrane 32 in the emulsion purification mechanism 3, and the oil phase after passing through the emulsion purification membrane 32 is discharged through the oil phase outlet 312, and is discharged by the emulsion purification membrane 32 The trapped emul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com