Gap compensation positioning device and method for fork-shaped part

A technology of gap compensation and positioning device, which is applied in workpiece clamping devices, metal processing, metal processing equipment, etc., can solve the problem of gap uniformity, low controllability of the fit on both sides, and coordination of the installation of the hinge mechanism. Large and fork-shaped parts have low center accuracy and other problems, so as to achieve the effects of convenient on-site management, high fitting accuracy and reliable compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

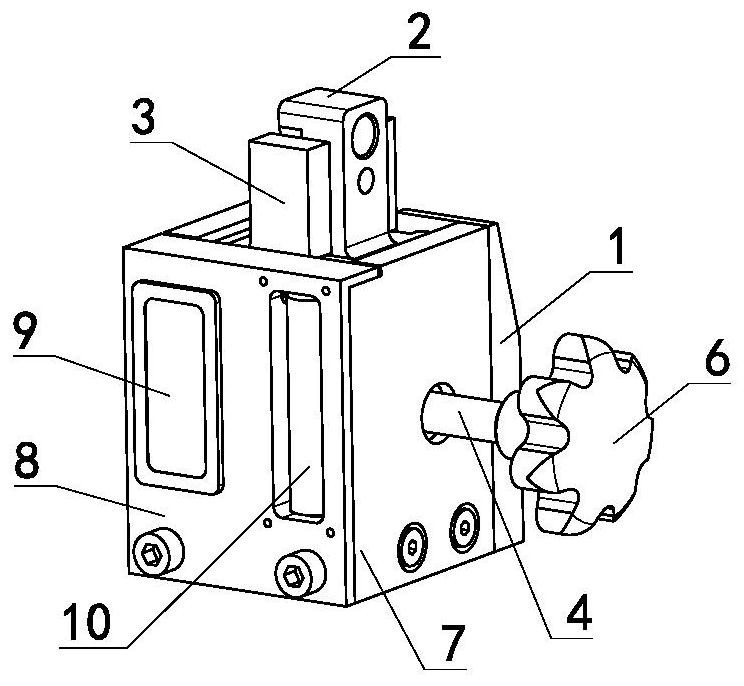

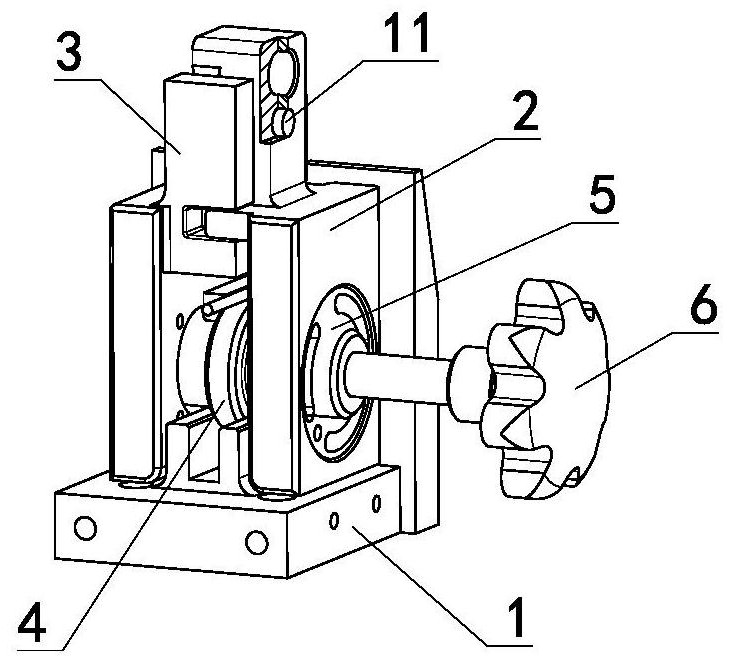

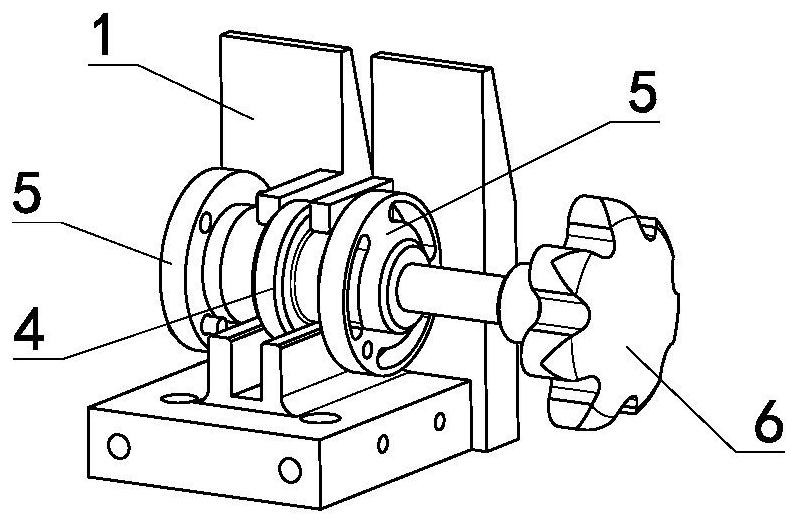

[0024] Reference attached Figure 1-6 As shown, a gap compensation positioning device for fork-shaped parts includes a base 1, a handle 6, an adjusting screw 4, a flange bush 5, positive positioning jaws 3, reverse positioning jaws 2, multiple end sensors 11, miniature Display 9, side baffle 7, front baffle 8. The base 1 is an L-shaped structure, with a vertical slot on both inner sides, the adjusting screw 4 is a stepped structure, the large circle in the middle is a chuck matching the vertical slot, and the flange bushing 5 is set on both ends of the adjusting screw 4 , the handle 6 is installed on the end of the adjusting screw 4, and the corresponding position on the forward / reverse positioning jaw 3 / 2 is provided with a pre-embedded hole of the end sensor 11, and a plurality of end sensors 11 are fixed in the pre-embedded hole, and the reverse positioning jaw 2 There are product positioning holes on it, the positive positioning jaw 3 and the reverse positioning jaw 2 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com