Aluminum container

A container and box body technology, applied in the field of aluminum containers, can solve the problem of large container load, and achieve the effects of large cargo capacity, reduced transportation difficulties, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

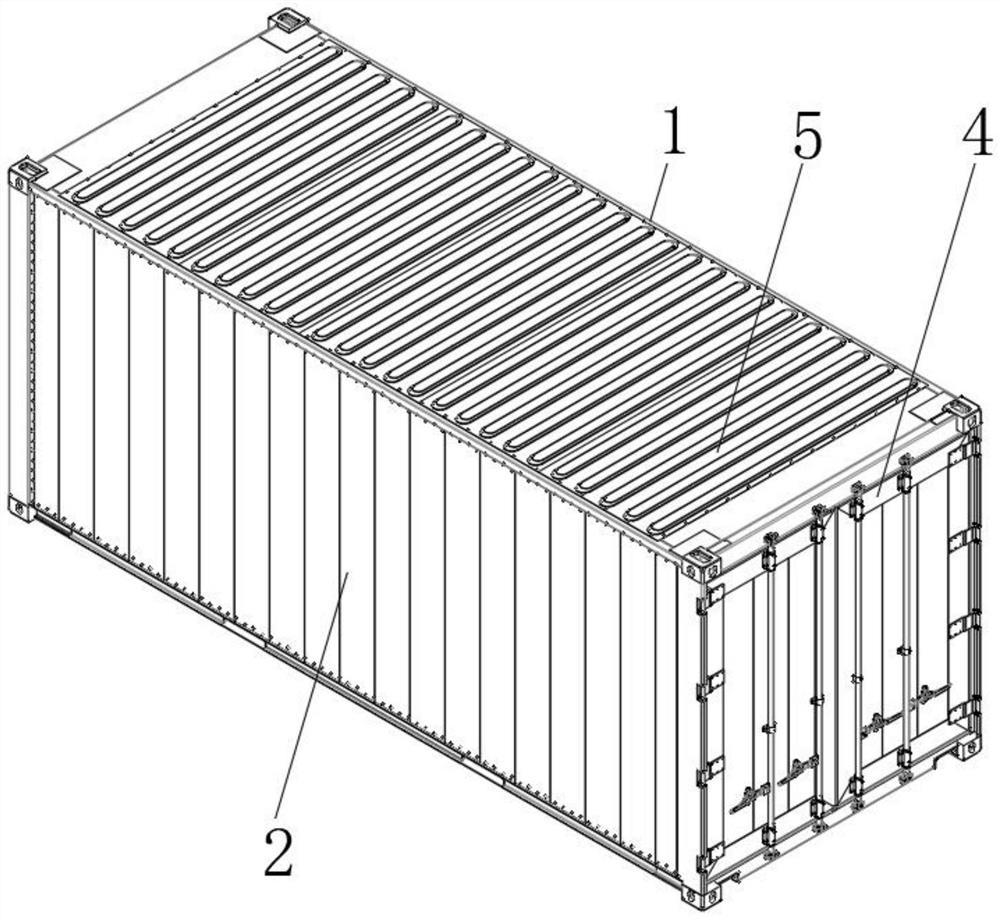

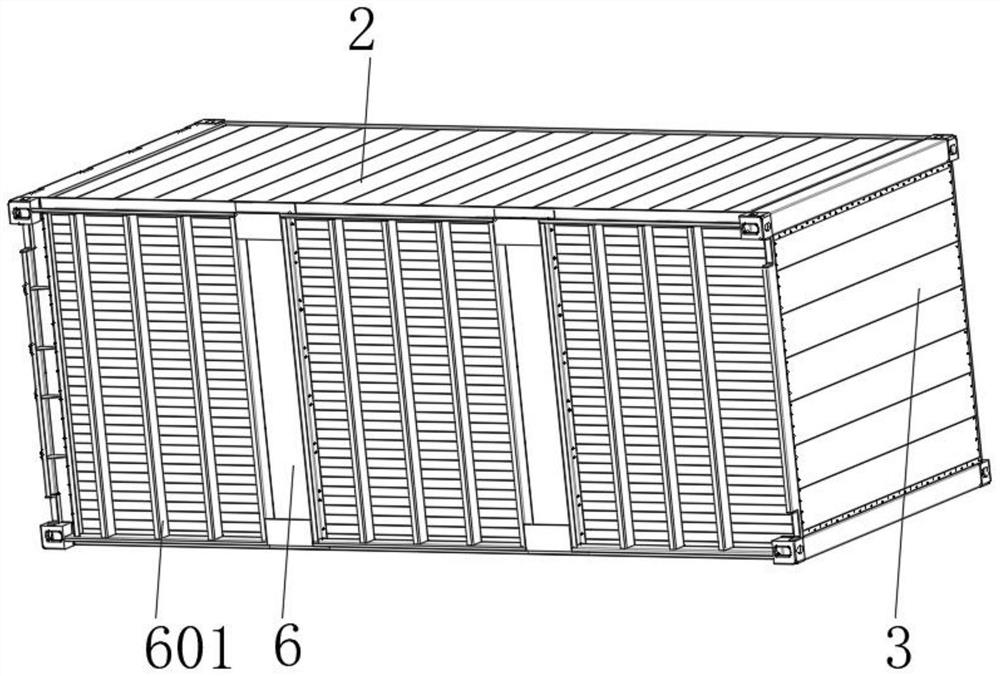

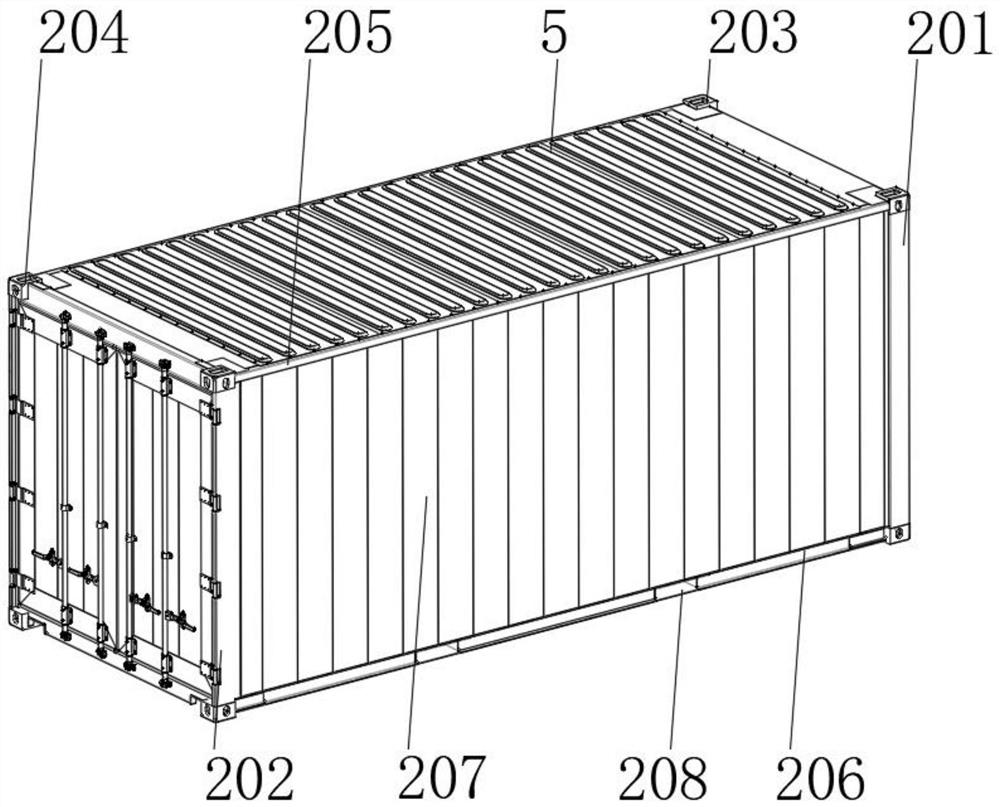

[0036] Such as Figure 1-11As shown, an aluminum container includes a whole box body 1, the whole box body 1 includes a side wall 2, a front end 3, a rear end 4, a top cover 5 and a bottom end 6, and the side wall 2 includes a front corner post 201 and a rear corner post 202 The two ends of the front corner post 201 are provided with front corner pieces 203, the two ends of the rear corner post 202 are provided with rear corner pieces 204, the top side beam 205 is welded between the front corner piece 203 and the rear corner piece 204 at the head end, and the end front corner piece 203 The bottom side beam 206 is welded between the rear corner piece 204, the side plate 207 is arranged in an array between the top side beam 205 and the bottom side beam 206, the side of the bottom side beam 206 has a fork groove 208, the front corner piece 203 and the rear corner Components 204 are welded with front corner post 201 and rear corner post 202 respectively. The side plate 207 is a ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com