A multi-component hybrid inorganic single-shell multi-temperature zone phase-change microcapsule and its preparation method

A technology of phase-change microcapsules and inorganic shells, applied in chemical instruments and methods, luminescent materials, heat exchange materials, etc., can solve problems such as poor strength and compactness, non-functional properties, and limited application scenarios, and achieve Uniform and controllable particle size, good strength and compactness, and wide application scenarios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

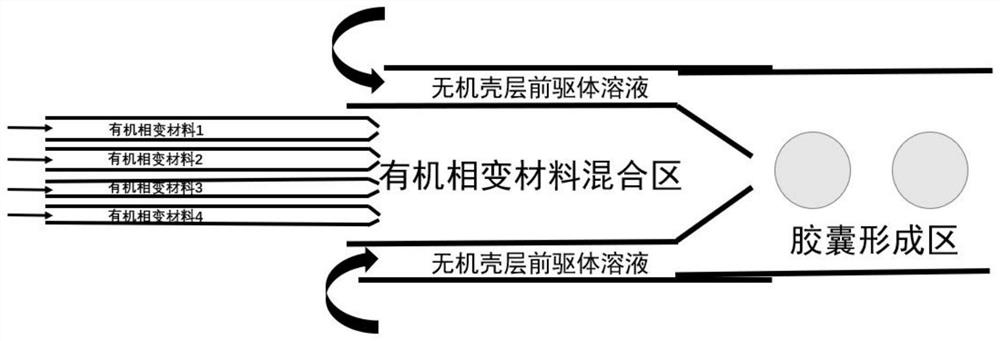

[0039] ZrO 2 / TiO 2Preparation of multi-component hybrid inorganic single-shell multi-temperature phase change microcapsules coated with n-octadecane / n-eicosane

[0040] (1) Weigh 6g of tetra-n-propyl zirconate (NPZ) and 10g of n-eicosane and mix them, stir at 50°C for 50min, the formed homogeneous oil phase is the organic phase change material phase 1; weigh 6g of titanium Tetrabutyl acid (TBT) and 10g n-octadecane were mixed together, stirred at 50°C for 50min, the formed homogeneous oil phase was the 2nd phase of organic phase change material; 2g poly(ethylene oxide-propylene oxide) was weighed - co-ethylene oxide) in 200 mL of formamide, stirred at 50 ° C for 30 min, the formed homogeneous solution is the inorganic shell precursor solution; the two organic phase change materials and the inorganic shell precursor solutions were respectively Fixed on the injection device.

[0041] (2) prepare 100mL formamide solution containing 4g deionized water as reaction outer phase, ...

Embodiment 2

[0049] SnO 2 Preparation of multi-component hybrid inorganic single-shell multi-temperature phase-change microcapsules coated with n-tetradecane / n-hexadecane / ZnO shell

[0050] (1) Weigh 20g of tetradecane as the first phase of the organic phase change material; take 20g of n-hexadecane as the second phase of the organic phase change material; Weigh 11g of Zn(CH 3 COO) 2 ·2H 2 O, 8g tin chloride dihydrate (SnCl 2 .2H 2 O), 2g sodium n-dodecyl sulfate in 200mL formamide, stirred at 55 ℃ for 1h, the formed homogeneous solution is the inorganic shell precursor solution; the organic phase change material and the inorganic shell precursor are mixed The solution is immobilized on the injection device.

[0051] (2) prepare 100mL aqueous solution containing 10g NaOH as reaction outer phase, place in beaker for subsequent use;

[0052] (3) injecting the two organic phase change materials into the organic phase change material tube respectively through the injection device, the tw...

Embodiment 3

[0058] ZrO 2 / SiO 2 / TiO 2 Preparation of multi-component hybrid inorganic single-shell multi-temperature phase change microcapsules coated with n-tetradecane / n-hexadecane shell

[0059] (1) Weigh and mix 3 g of tetra-n-propyl zirconate (NPZ), 2 g of tetraethyl orthosilicate (TEOS), 2 g of tetrabutyl titanate (TBT), and 10 g of n-tetradecane at 50°C Stir for 50min, the formed homogeneous oil phase is the organic phase change material phase 1; weigh 3g tetra-n-propyl zirconate (NPZ), 2g tetraethyl orthosilicate (TEOS), 2g tetrabutyl titanate (TBT) ), 10g of n-hexadecane and mixed, and stirred at 50 ° C for 50min, the formed homogeneous oil phase was the 2-phase organic phase change material; Weigh 2g of hexadecyl trimethyl ammonium bromide (CTAB) in 200 mL of methanol In the amide, stirring at 50 °C for 20 min, the formed homogeneous solution is the inorganic shell precursor solution; the organic phase change material and the inorganic shell precursor solution are fixed on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com