Actuator connecting mechanism, bypass supercharger and vehicle

A connecting mechanism and actuator technology, which is applied in the field of actuator connecting mechanism, bypass supercharger and vehicles, can solve the problems affecting customer experience, bypass crank structure vibration, etc., to reduce vibration and seat noise and percussion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

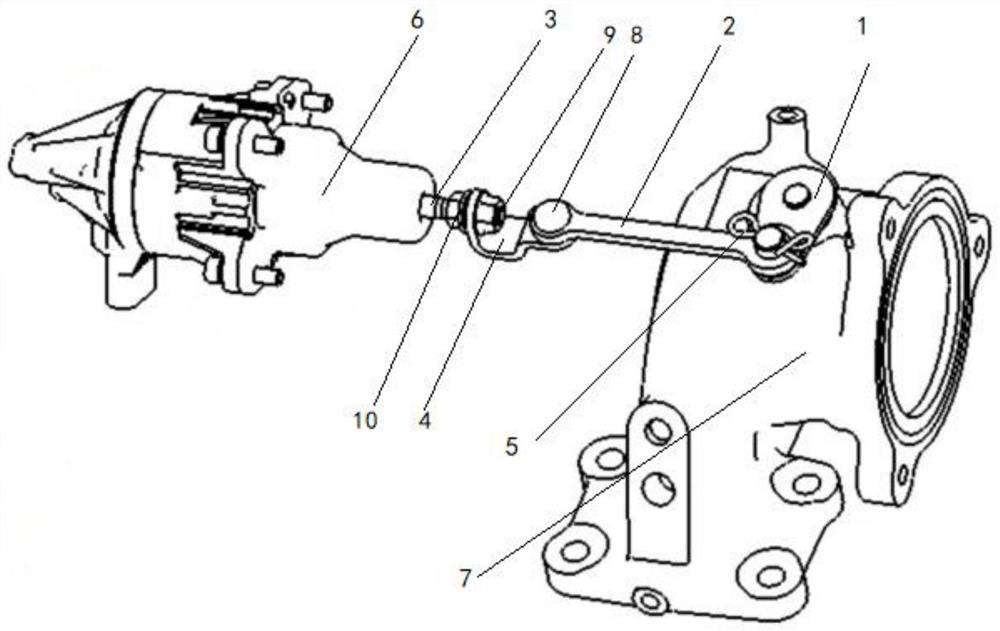

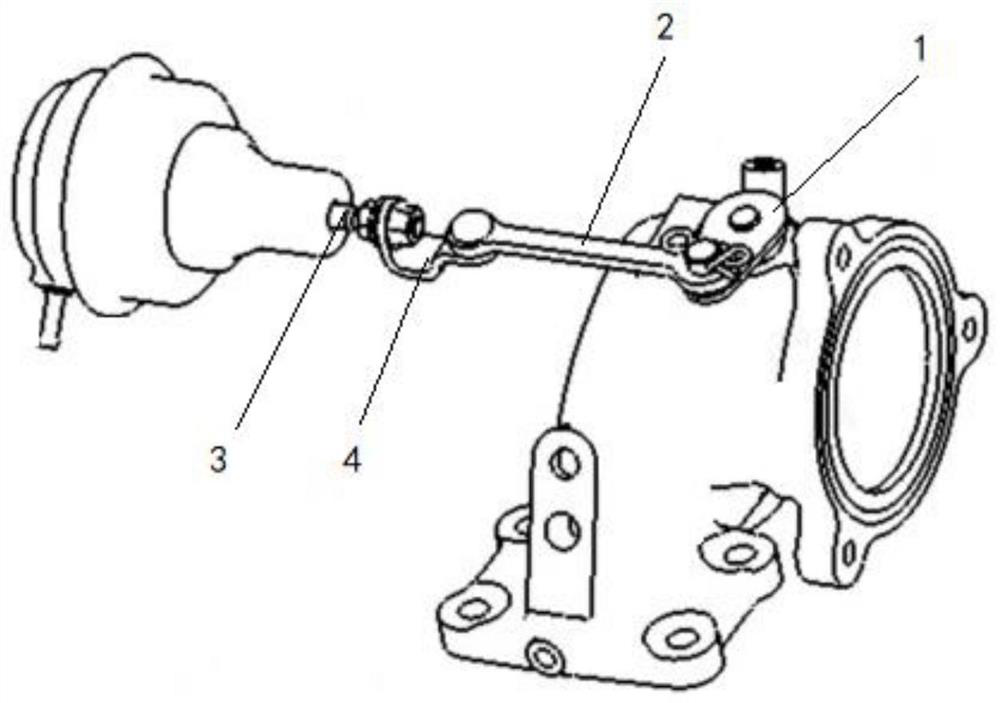

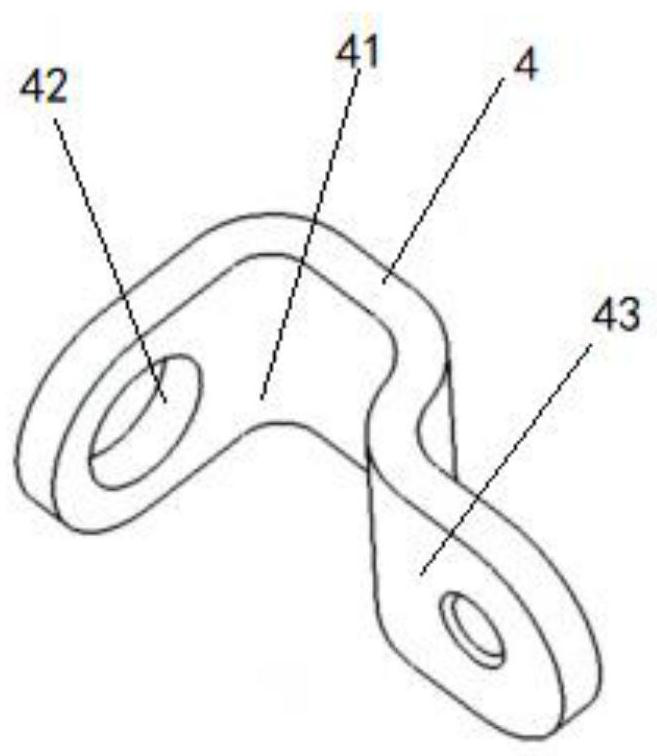

[0026] like Figure 1-Figure 3 As shown, an actuator connection mechanism provided by the present invention includes a linkage crank 1, a first actuator rod 2, a second actuator rod 3 and a connecting frame 4; The air valve 7 is connected, the second actuator rod 3 is used to connect with the actuator 6, one end of the first actuator rod 2 is connected with the linkage crank 1, and the other end of the first actuator rod 2 is connected with the second actuator rod 3 through the connecting frame 4 , the connecting frame 4 has a curved portion of the opening 41, and two connecting positions 42 respectively located on both sides of the opening 41 are provided on the curved portion to connect the first actuator rod 2 and the second actuator rod 3 respectively, so that the connector frame 4 In ensuring the movement accuracy of the connection mechanism and the actuator 6, having a certain pressure bearing and deformation bearing capacity, it can effectively absorb the pulse generate...

Embodiment 2

[0042] Based on the same inventive concept, the present invention also provides a bypass supercharger, including the actuator connection mechanism provided in Embodiment 1, that is, the actuator 6 of the bypass supercharger is connected through the actuator in Embodiment 1 The mechanism is connected with the bleed valve 7 of the bypass supercharger, so the bypass supercharger provided by this embodiment has all the beneficial effects of the actuator connection mechanism of the first embodiment. In this embodiment, the structure and type of the bypass supercharger are not specifically limited, and it can be any bypass supercharger on the market. At the same time, the type of actuator 6 selected for the bypass supercharger is not limited, and can be An actuator 6 of any working mode, such as a vacuum control actuator 6 and an electronically controlled actuator 6 . For other unspecified structures of the bypass supercharger, reference may be made to relevant publications in the p...

Embodiment 3

[0045] Based on the same inventive concept, the present invention also provides a vehicle, including the bypass supercharger provided in Embodiment 2, that is, the actuator connection mechanism in Embodiment 1 is used to complete the connection between the air release valve 7 and the bypass supercharger. Actuator 6 connections. The present invention does not specifically limit the type and type of the vehicle. It can be any vehicle in the prior art, such as a family car, passenger car, truck, etc. Other unspecified structures of the vehicle can refer to relevant disclosures in the prior art. , no expansion description will be made here.

[0046] Through the above embodiments, the present invention has the following beneficial effects or advantages:

[0047] 1) The present invention divides the complete connecting rod between the actuator and the waste gas valve into the first actuator rod and the second actuator rod, resists the pulse generated by the pressure through the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com