Air bath type plasma melting machine and plasma leakage detection method

An air-bath-type, plasma-melting technology, which is applied in the testing of machines/structural components, measuring devices, blood transfusion devices, etc., can solve problems that are difficult to find, affect the melting environment of the air bath, and leak plasma, so as to improve the efficiency of plasma melting , realize real-time detection and alarm, and avoid adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

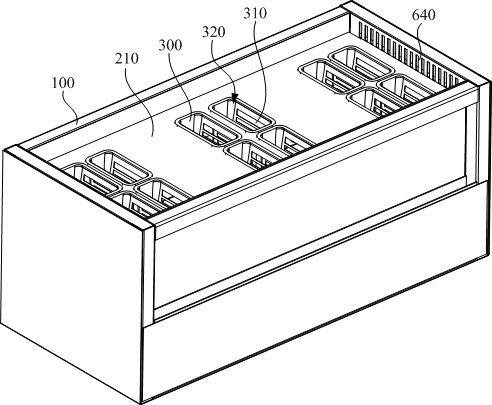

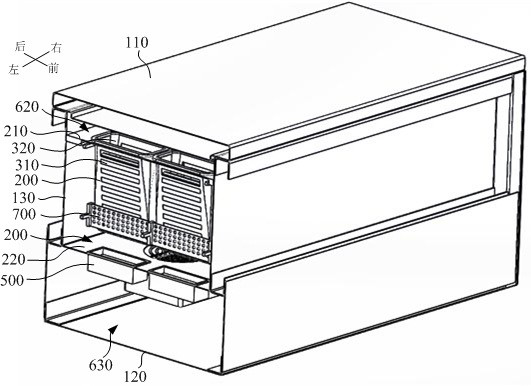

[0057] This example discloses a gas baffing machine, reference Figure 1 to 5 , Including the box 100, the casing 100 constitutes an outer contour of the entire device.

[0058] The casing 100 in this embodiment is a rectangular component, and the gas bath 200 is provided in the box 100. The gas bath is circulated in the gas bath, which generates heat exchange between heat gas and the low-temperature blood slurry bag of to be melted to achieve the target of the slurry.

[0059] The heat gas is supplied by the heating unit 400, and the heating portion 400 is used to deliver hot air in the air bathroom 200.

[0060] The gasket portion 300 for placing the blood slurry bag is placed in the spring portion 300.

[0061] A gas bath 200 is provided with a gas supply channel between the inner wall of the casing 100, and the gas in the air bathroom 200 is returned to the heating portion 400 via the return air passage. After the heating portion 400 is reheated, then flow into the gas bathroom...

Embodiment 2

[0128] This example discloses a plasma leak detection method, and is applied to the disclosed air pieces of the gas bars of the air.

[0129] This detection method includes:

[0130] The liquid from the slouching portion 300 falls into the water supply portion 500;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com