Geological and geotechnical investigation strength test sampling device

A technique of strength test and sampling device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

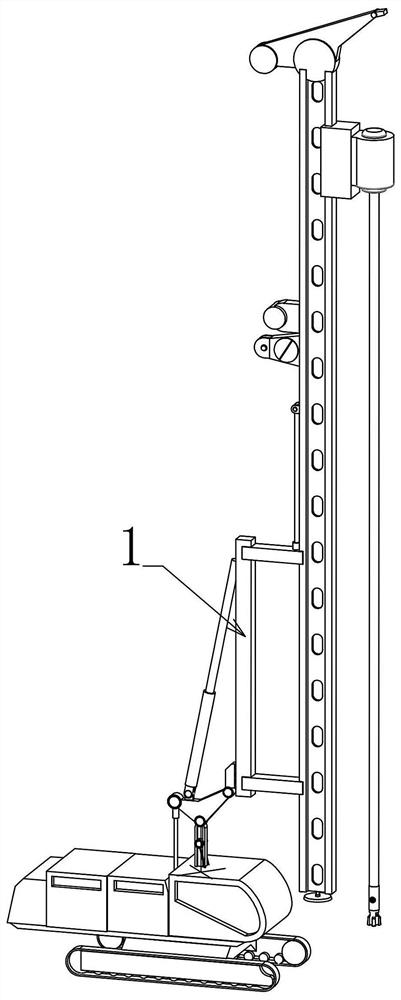

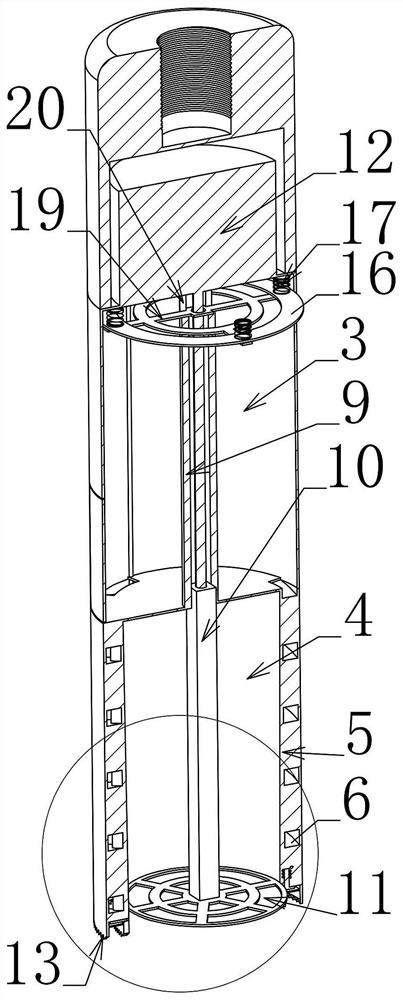

[0033] The following is attached Figure 1-14 The specific implementation manners of the present invention are further described in detail.

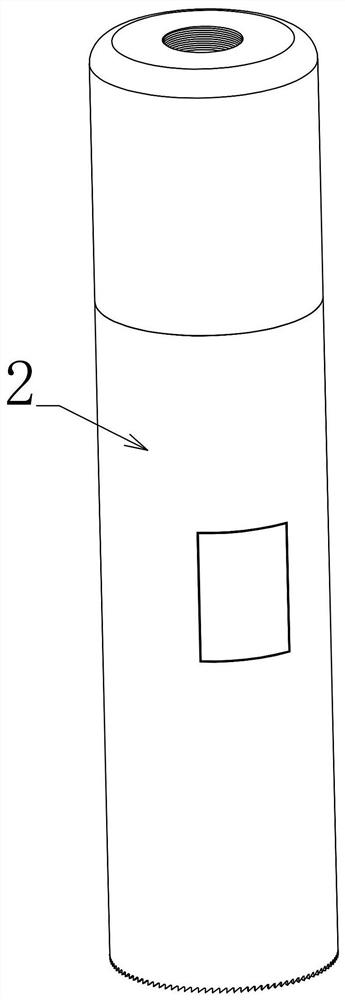

[0034] When this embodiment is in use, the sampling cylinder 2 is divided into upper and lower chambers, the upper chamber 3 is provided with a vertically arranged guide rod 9, the guide rod 9 is a hollow structure and the hollow part communicates with the lower chamber 4, The guide rod 9 is vertically slidably connected with a pressing rod 10, the upper end of the pressing rod 10 is driven up and down by the drive motor 12 fixedly connected to the upper chamber 3, and the lower end of the pressing rod 10 is fixedly connected with a pressing plate 11, which is It is vertically slidingly connected with the inner contour of the sampling cylinder 2. The lower part of the lower chamber is provided with a cutting layer 5, and a plurality of cutting teeth 8 are rotatably connected to the cutting layer 5. When each cutting tooth 8 is extended, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com