Production line body parameter monitoring method and system

A monitoring system and production line technology, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as parts batch accidents, and achieve the effect of ensuring traceability, realizing alarm and timely processing, and eliminating product quality accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

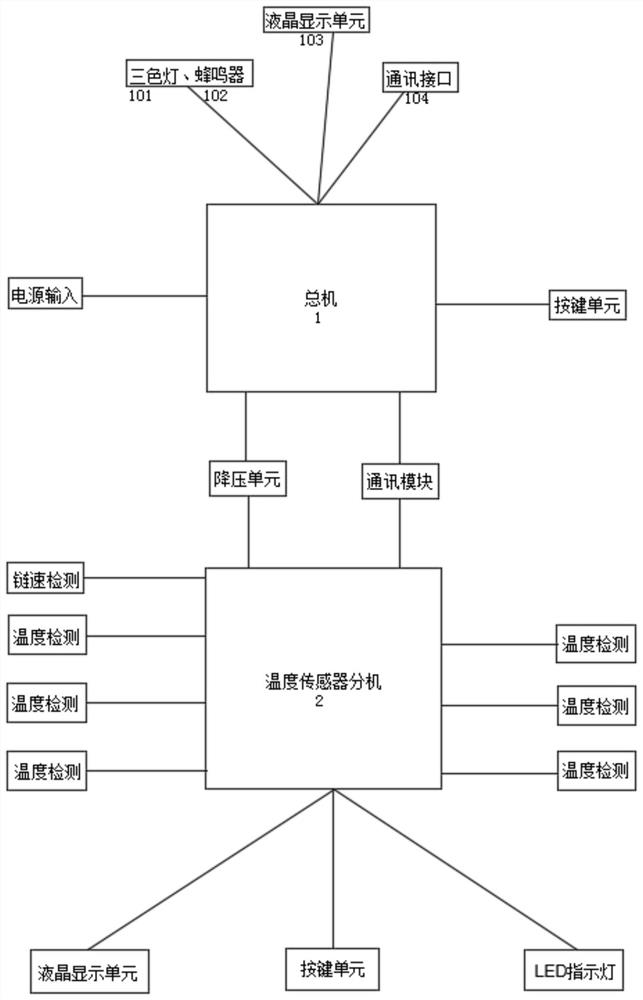

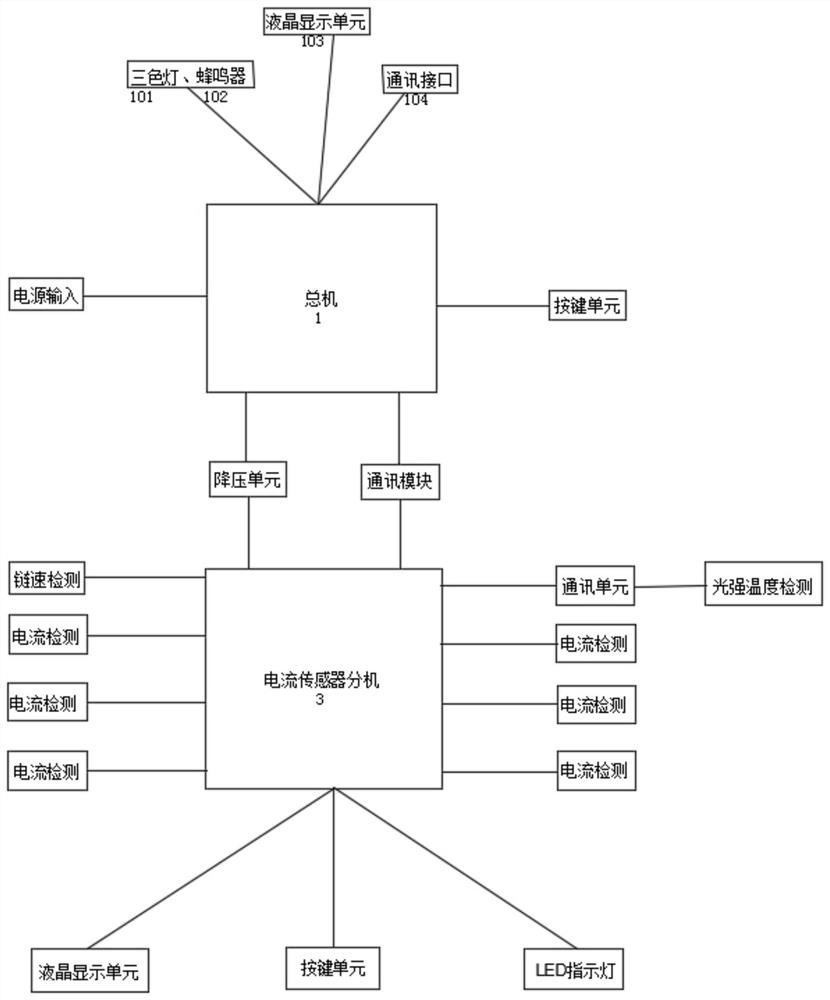

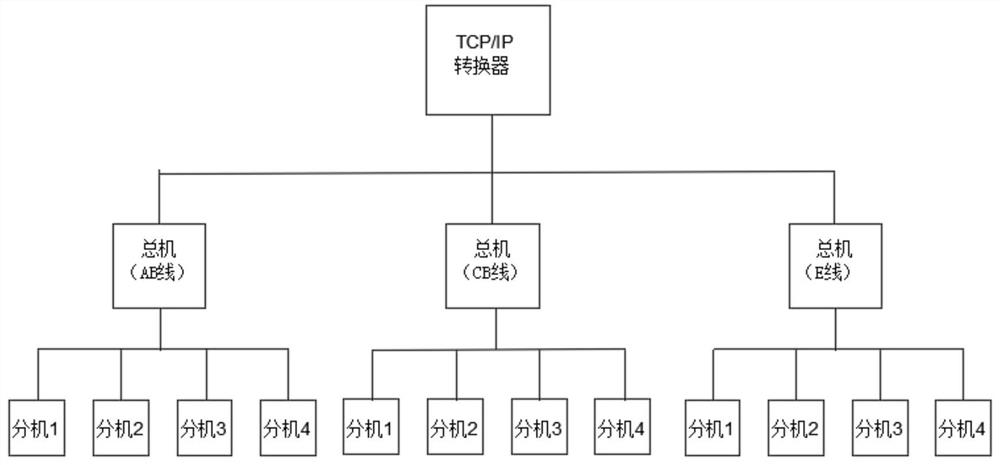

[0041] now attached Figure 1-3 Description and embodiment further illustrate the present invention:

[0042] A method for monitoring parameters of a production body, comprising the following steps:

[0043] S1. By collecting the process parameters of the production line body, the process parameter data is obtained and sent to the central controller. The process parameters are: light intensity, current, temperature, chain speed, and the light intensity data is obtained through collection Calculate the current light intensity data based on the received current data;

[0044] S2. The central controller transmits the data to the central server at the same time, and the central server stores the data into the database of the data management system to realize real-time data collection and automatic recording;

[0045] S3, through real-time monitoring of process parameter data, when the monitoring parameters are abnormal, an automatic alarm prompt is given;

[0046] S4. The data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com