3D printing vending machine

A vending machine and 3D printing technology, applied in the field of 3D printing, can solve the problems of low transmission accuracy, complex structure, printing paper waste, etc., and achieve the effect of improving transportation accuracy, stable transmission, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

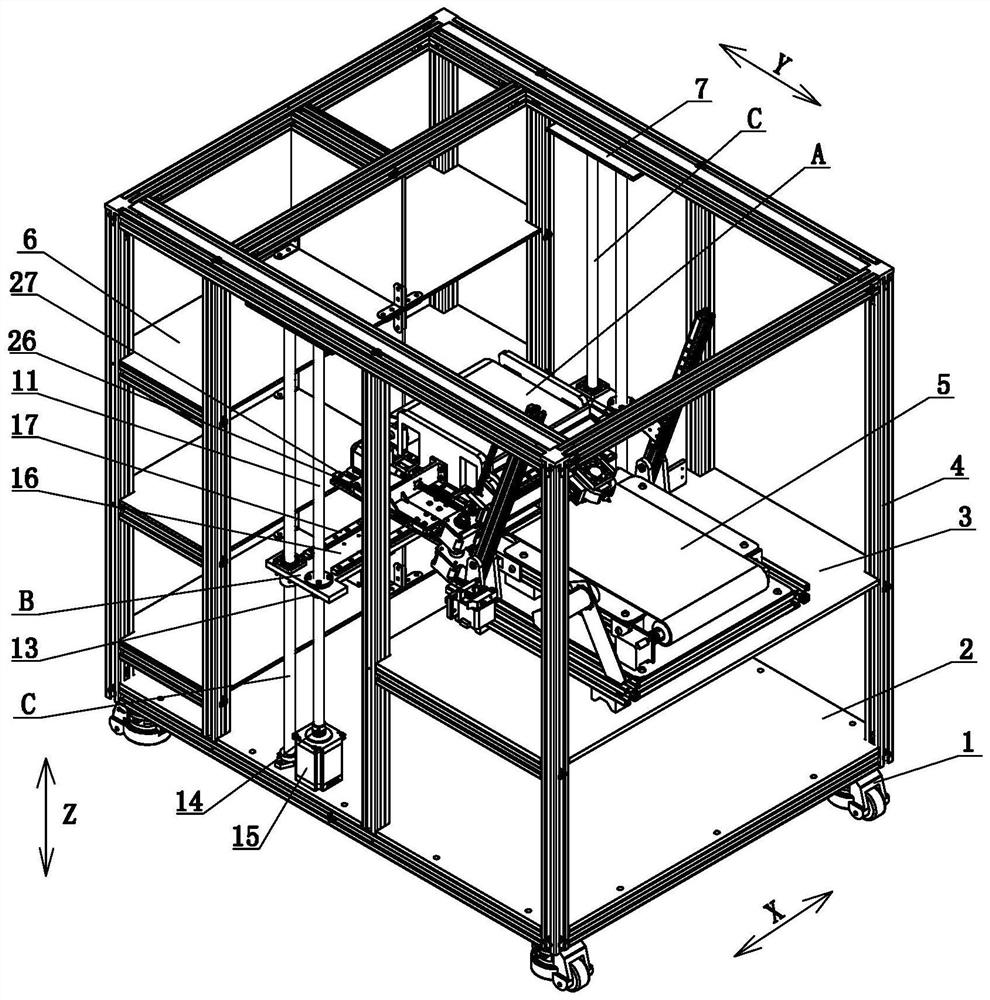

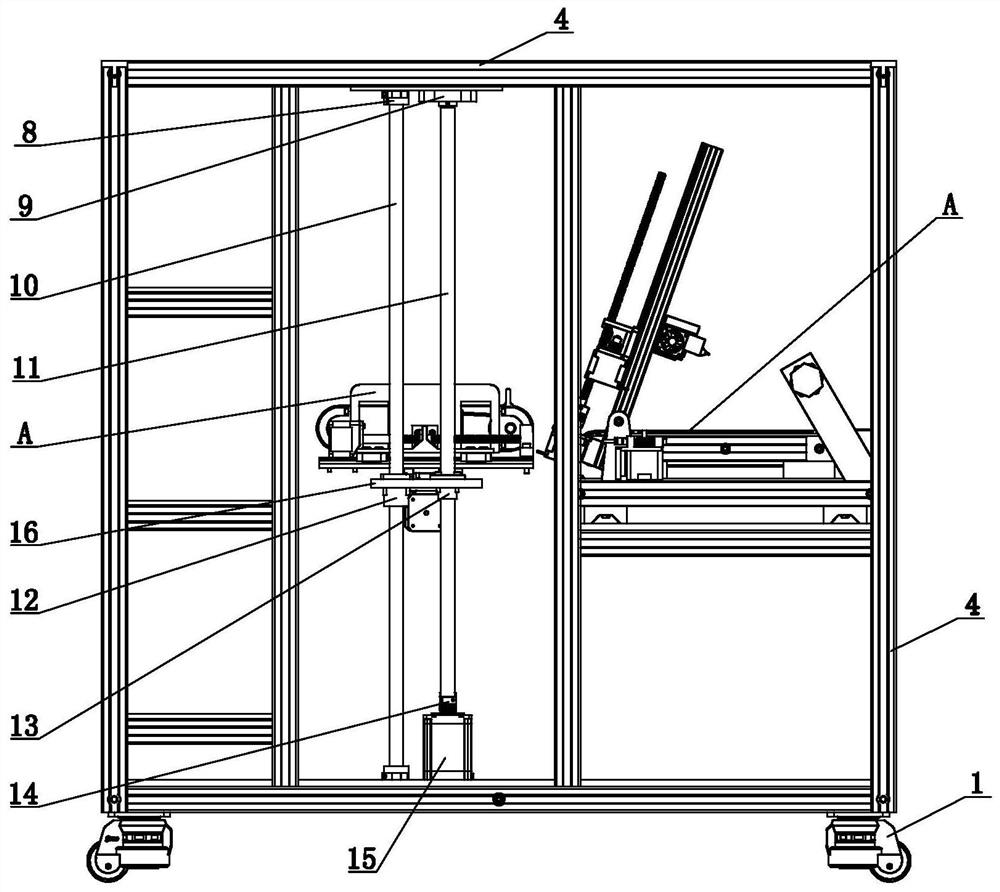

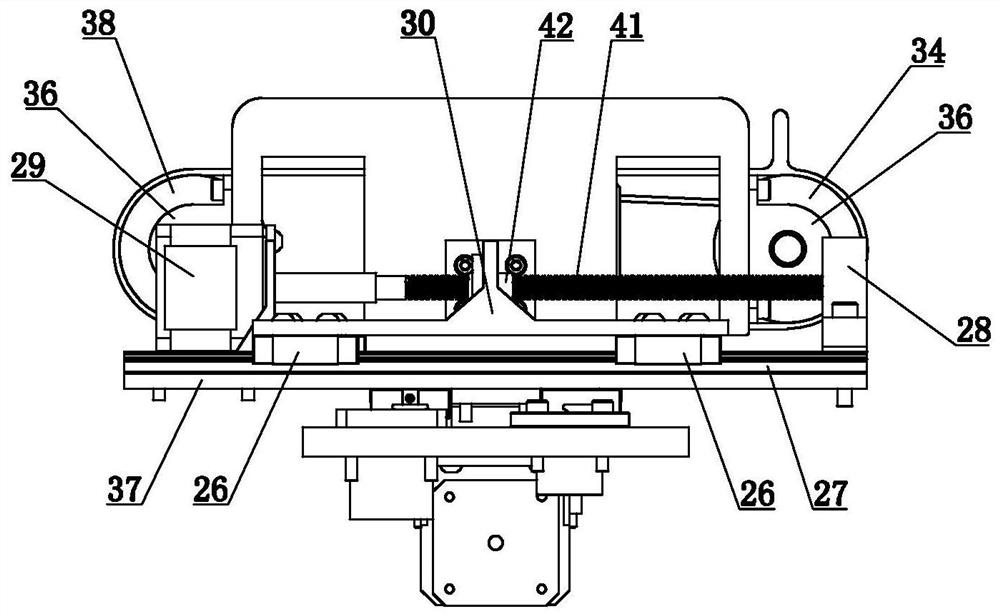

[0022] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this embodiment, this embodiment includes printer 5, transportation system and frame mechanism;

[0023] The frame mechanism includes a Fuma wheel 1, a frame bottom plate 2, a printer fixing plate 3, a frame body 4 and a storage rack 6, the frame body 4 is a rectangular three-dimensional frame, the frame bottom plate 2 is fixed on the bottom of the frame body 4, and the printer fixing plate 3 is set On one side in the frame body 4, the storage rack 6 is arranged on the other side in the frame body 4, and the printer fixing plate 3 is arranged on the top of the frame body 4 in parallel, and is fixed on the frame body 4, and the bottom of the frame body 4 The four corners are fixed with the Fuma wheel 1, and the printer 5 is fixed on the printer fixing plate 3;

[0024] The transportation system includes an X-axis motion mechanism A, a Y-axis motion mechanism B and two sets of Z-axis motion mechanis...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap