A kind of aramid fiber composite diaphragm based on in-situ modification, its preparation method and application

An in-situ modification and composite diaphragm technology, which is applied in the application field of aramid composite diaphragm and lithium-sulfur battery, can solve the problems of complex process, difficulty in inhibiting lithium-sulfur battery polysulfide shuttle, and little improvement in battery performance. Achieve the effects of simple and controllable process, easy continuous industrial production, enhanced thermal stability and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

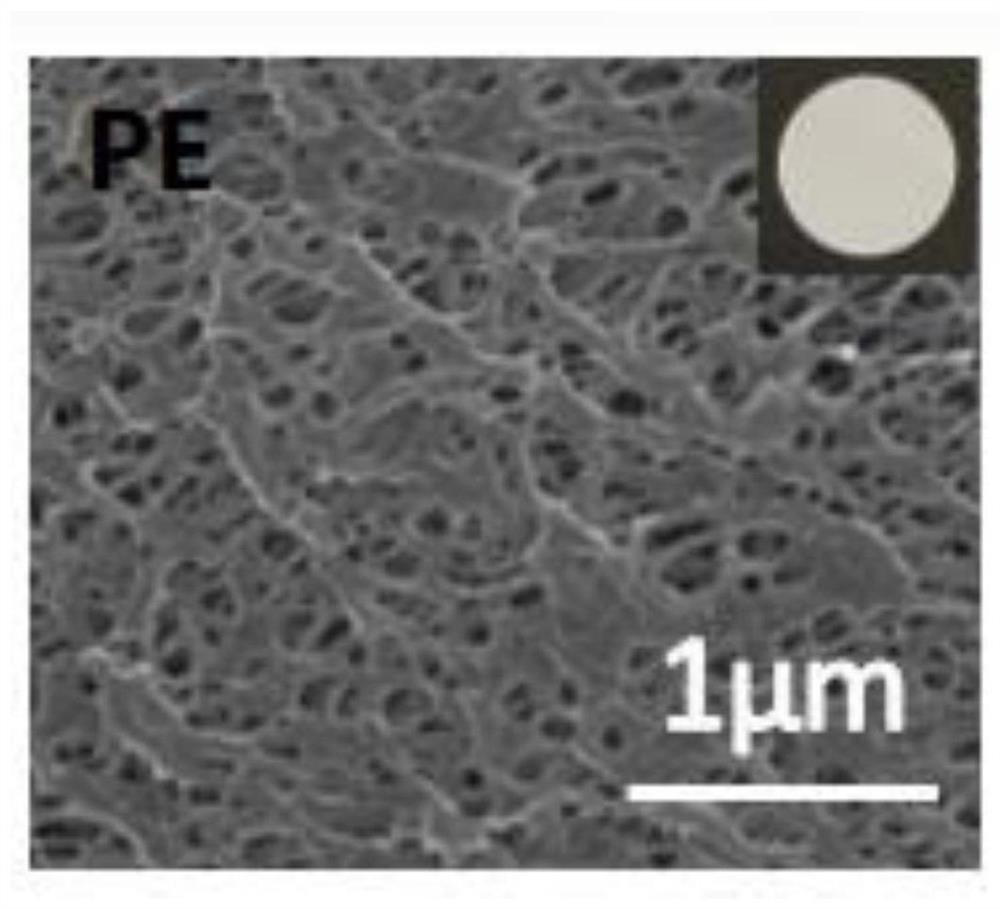

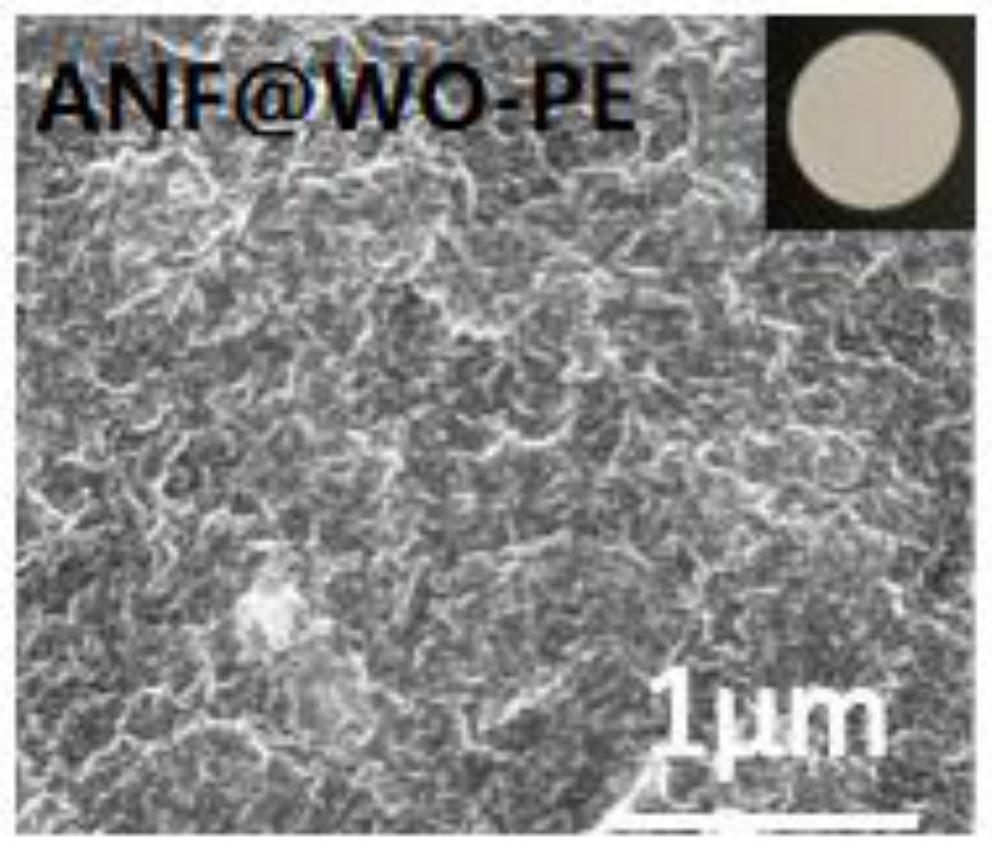

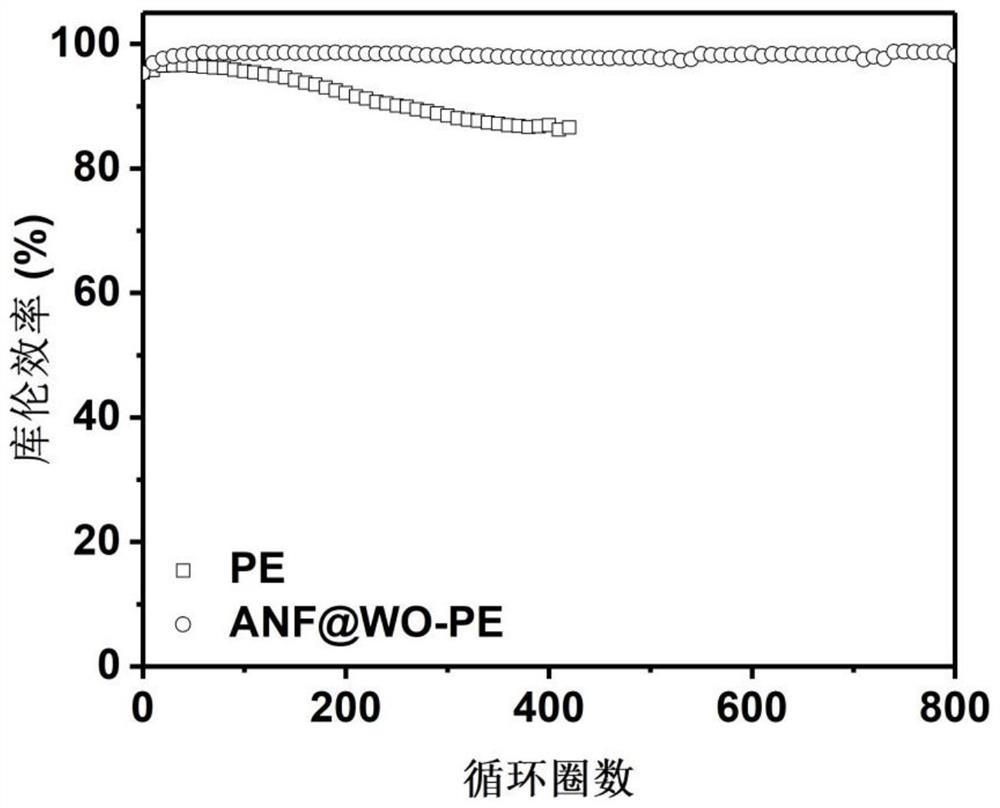

[0038] An aramid composite diaphragm based on in-situ modification, including a polyethylene microporous diaphragm base film and an aramid composite coating coated on one side of the base film. The aramid composite coating is modified in situ by functional nanoparticles of tungsten oxide It is coated with aramid nanofibers; the thickness of the polyethylene microporous diaphragm is 5 μm, and the porosity is 30%; the aramid fiber is para-aramid fiber, and the molecular weight is 5000-10000Da; The ratio is 1:10; the thickness of the aramid composite coating is 0.5 μm.

[0039] The preparation method of the aramid fiber composite diaphragm based on in-situ modification comprises the following steps:

[0040] (1) Preparation of aramid fiber solution: Take 12g of aramid fiber, 12g of potassium hydroxide, 12ml of water and 1160ml of dimethyl sulfoxide, and stir continuously for 8 hours at 20°C to completely dissolve the aramid fiber to obtain aramid fiber solution;

[0041] (2) Pr...

Embodiment 2

[0049] An aramid composite diaphragm based on in-situ modification, including a polyethylene microporous diaphragm base film and an aramid composite coating coated on one side of the base film. The aramid composite coating is modified in situ by functional nanoparticles ZIF- 67 aramid nanofiber coated; polyethylene microporous membrane thickness is 16μm, porosity is 40%; aramid fiber is para-aramid fiber, molecular weight is 10000-100000Da; ZIF-67 and aramid nanofiber The mass ratio of the aramid composite coating is 1:1; the thickness of the aramid composite coating is 10 μm.

[0050] The preparation method of the aramid fiber composite diaphragm based on in-situ modification comprises the following steps:

[0051] (1) Preparation of aramid fiber solution: Take 12g of aramid fiber, 24g of potassium tert-butoxide, 24ml of methanol and 180ml of dimethyl sulfoxide, and stir continuously for 2 hours at 100°C to completely dissolve the aramid fiber to obtain aramid fiber solution...

Embodiment 3

[0059] An aramid composite diaphragm based on in-situ modification, including a polypropylene microporous diaphragm base film and an aramid composite coating coated on one side of the base film. The aramid composite coating is modified by in-situ modified functional nanoparticles disulfide Coated with molybdenum aramid nanofibers; polypropylene microporous diaphragm with a thickness of 40 μm and a porosity of 50%; aramid fibers are para-aramid fibers with a molecular weight of 10000-100000Da; molybdenum disulfide and aramid nanofibers The mass ratio of the aramid composite coating is 1:2; the thickness of the aramid composite coating is 2 μm.

[0060] The preparation method of the aramid fiber composite diaphragm based on in-situ modification comprises the following steps:

[0061] (1) Preparation of aramid fiber solution: take 12g of aramid fiber, 18g of sodium hydroxide, 24ml of ethanol and 550ml of dimethyl sulfoxide, and stir continuously for 5 hours at 60°C to completely ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com