Silicon product production and processing-oriented protective screen shell for electrical element

A technology for electrical appliances and protective screens, applied in the direction of electrical components, electrical equipment shells/cabinets/drawers, electrical equipment structural parts, etc., can solve problems such as the decline in the heat dissipation effect of the filter, to prevent failures, prevent performance or damage, The effect of increasing the contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

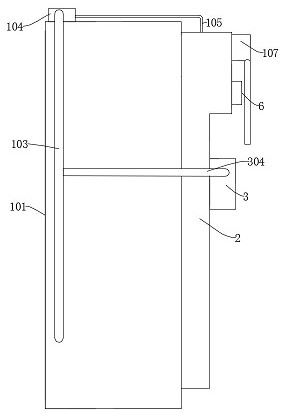

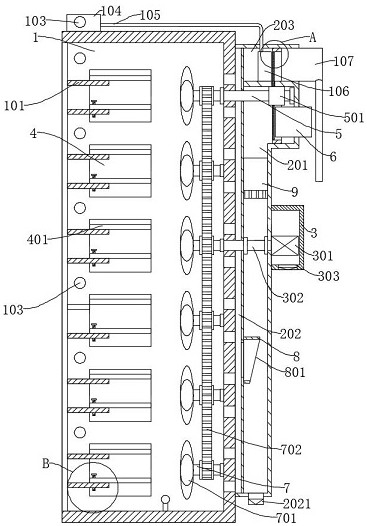

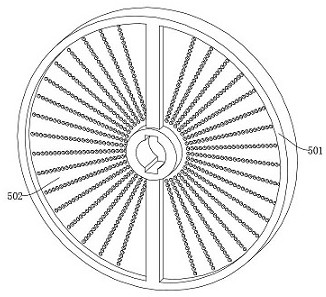

[0028] Example: refer to Figure 1-Figure 6 , a protective screen shell for electrical components used in the production and processing of silicon products, including a first installation box 1, and also includes: a second installation box 2 fixedly connected to the first installation box 1, and a second installation box 2 is provided in the second installation box 2 A cavity 201, a second cavity 202 and a third cavity 203, the first cavity 201 communicates with the second cavity 202, the second cavity 202 communicates with the first installation box 1; The installation shaft 5 in the cavity 201; the installation frame 501 fixedly connected on the installation shaft 5; the filter element 502 fixedly connected on the installation frame 501; the splitter box 106 fixedly connected in the third cavity 203; The inlet pipe 6 on the first cavity 201, the distribution box 106 and the inlet pipe 6 are distributed on both sides of the filter element 502; the exhaust port of the first in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com