System and method for simultaneous excavation and segment erection of TBM by thrust shell

A shell and propulsion technology, applied in shaft equipment, earthwork drilling, wellbore lining, etc., can solve problems such as spending more time and increasing time requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

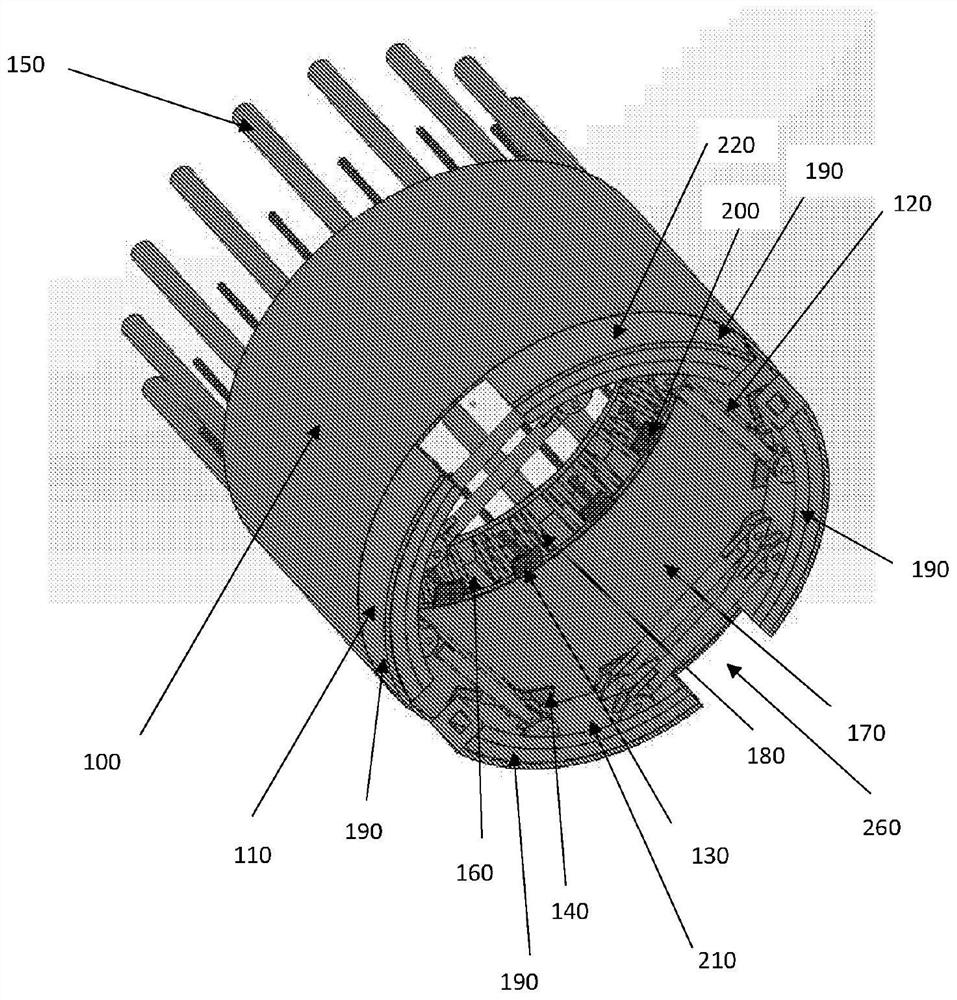

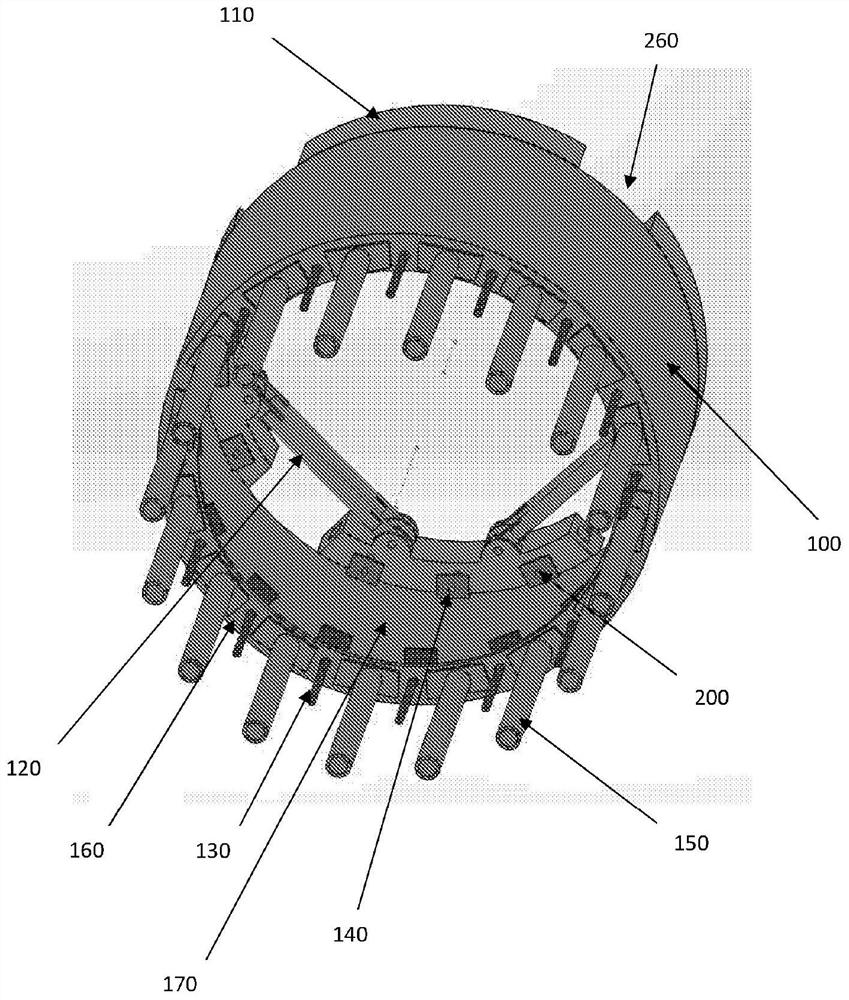

[0018] figure 1 and 2 A 3D view of a general propulsion housing 100 including a main hollow tank 170 and a propulsion ring 160 connected to a propulsion cylinder 150 of a TBM 310 is shown. Therefore, the movement (push / pull) of the propulsion housing 100 will be controlled by the propulsion cylinder 150 of the TBM 310 .

[0019] The ring of the propulsion housing may include stiffeners 180 on the propulsion ring 160 as structurally required. At the region of the propulsion ring 160, the thickness of the hollow tank 170 of the propulsion housing 100 may be structurally thicker. However, the extra thickness will be towards the inside of the pusher ring 160 .

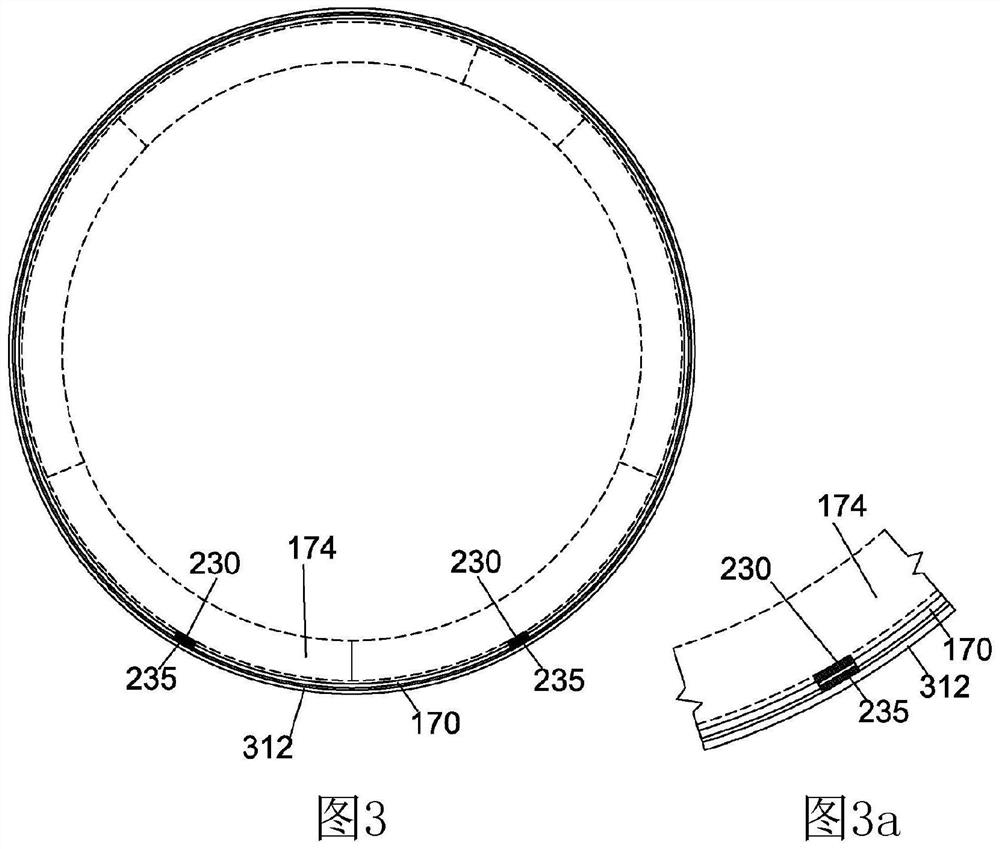

[0020] The hollow tank 170 will be able to move back and forth within the gap between the rear guard 312 of the TBM 310 and the segmented rings 172 / 174. Therefore, the ID of the push can 170 should be greater than the OD of the segmented rings 172 / 174 , and the OD of the push can 170 should be smaller than the ID of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com