Agricultural threshing machine with good corn kernel separation effect

A peeling machine and seed technology, applied in agricultural machinery and tools, application, agriculture, etc., can solve the problems of low safety, poor corn peeling effect, and poor output effect, and achieve the peeling effect Good, safe to use, fixed and firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

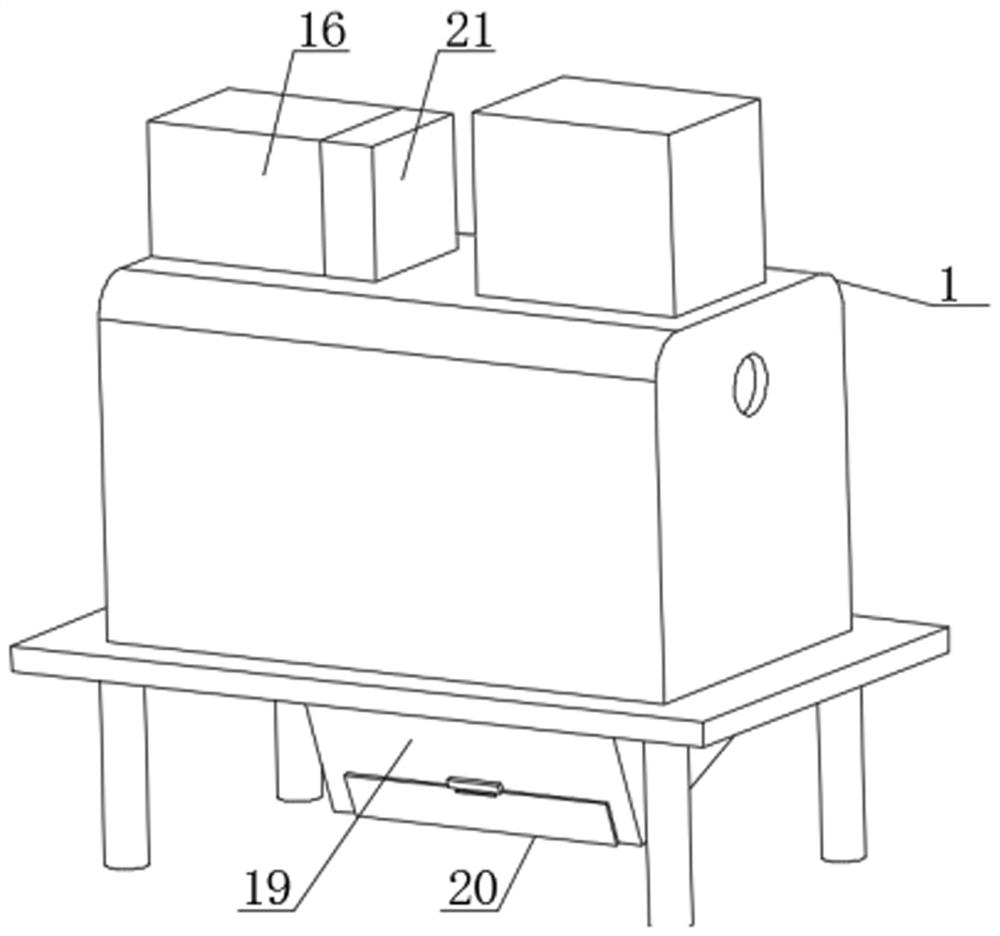

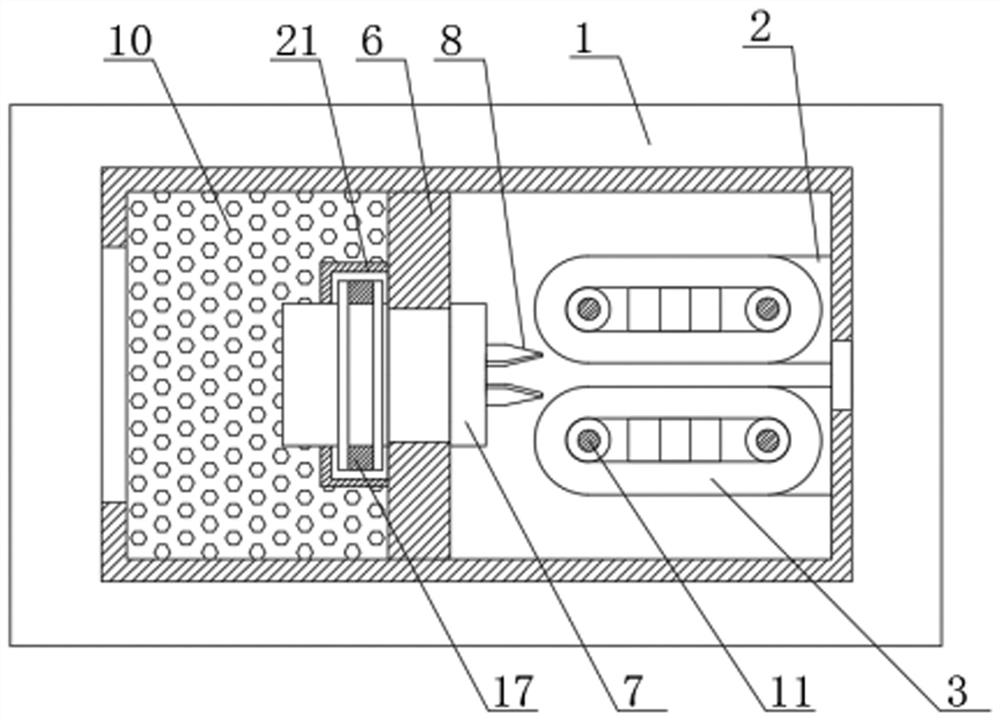

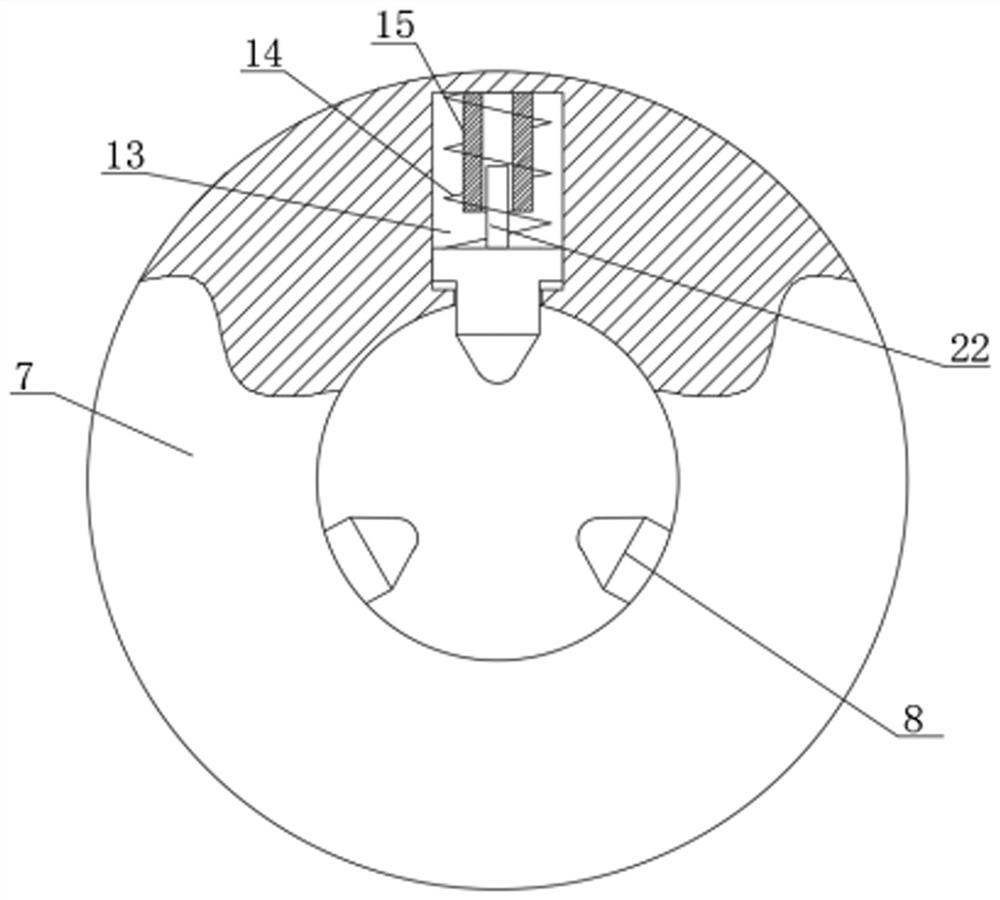

[0036] see Figure 1-7 As shown, the present invention is an agricultural peeling machine with good corn grain separation effect, including a base 1, a feeding assembly and a peeling assembly arranged above the inside of the base 1, and a distribution net 10 fixedly installed inside the base 1, The material distribution net 10 is inclined; the mesh of the material distribution net 10 can accommodate the passage of corn kernels, and is used for the separation of corn kernels and corn cobs, so that corn kernels and corn cobs are not mixed together after the corn kernels are peeled off. Case.

[0037] There are two groups of feeding components, which are distributed symmetrically inside the pedestal 1. The feeding components include a fixed plate 2 fixedly installed above the inside of the pedestal 1, a conveyor belt 3 movably connected above the fixed plate 2, and a conveyor belt 3 fixedly installed. The elastic block 4, the outer surface of the conveyor belt 3 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com