Impurity removal device for removing non-titanium impurities in titanium slag and screening equipment thereof

A screening equipment and impurity technology, applied in the industrial field, can solve the problem that metal impurities and other large impurities cannot be effectively removed, it is difficult to meet the requirements of removing non-titanium impurities, and it is easy to fall to the secondary screen below, etc. problems, to achieve the effect of improving the effect of impurity removal, promoting tissue changes, and fine screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

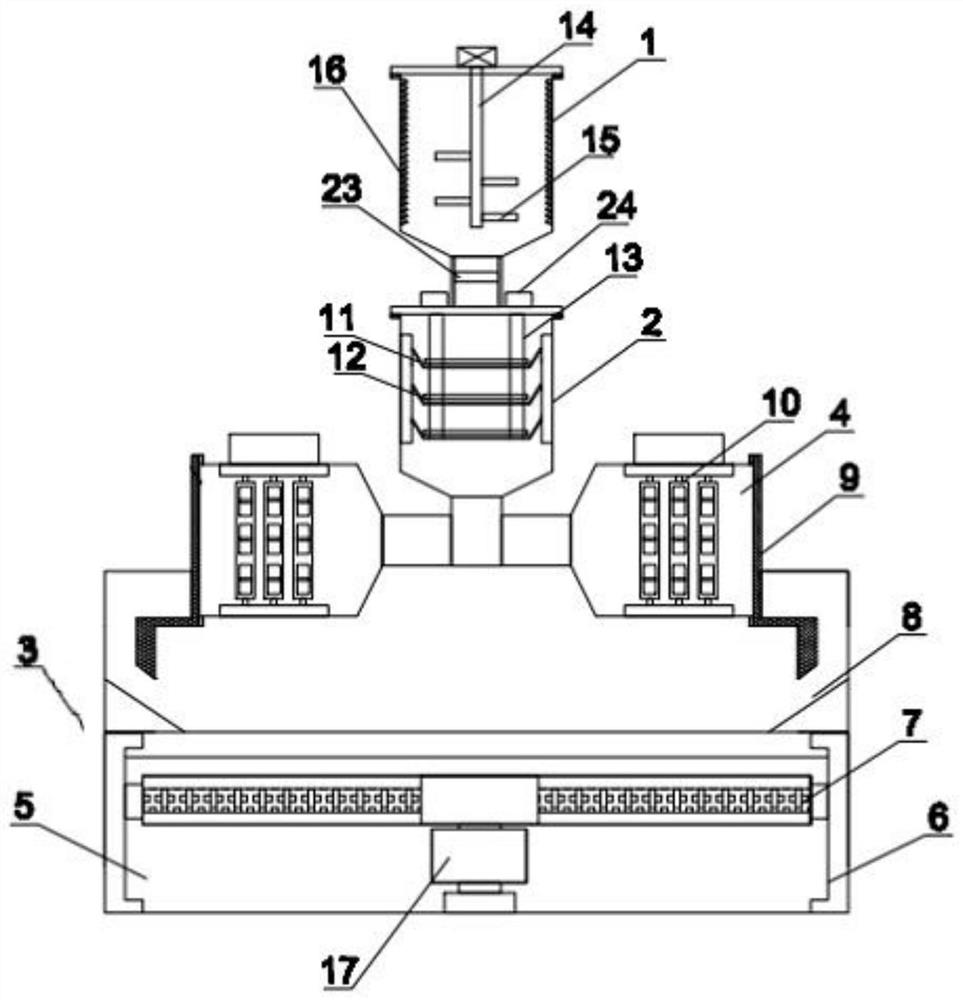

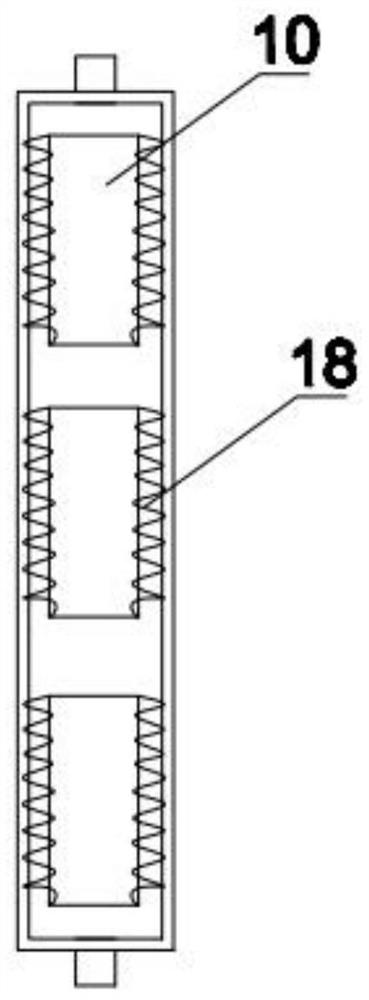

[0032] Such as Figure 1 to Figure 7 As shown, a device for removing impurities and screening equipment for removing non-titanium impurities in titanium slag, including an initial mixing chamber 1, a grinding powder sieving chamber 2, an impurity removal chamber 4, and a sieving tank 5. The initial mixing chamber 1 The bottom is fixedly connected with the grinding powder sieve chamber 2, and the left and right ends of the grinding powder sieve chamber 2 are connected to the impurity removal chamber 4 through connectors, and the outlets provided at the left and right ends of the impurity removal chamber 4 are located in the placement chamber 8 Inside, a high-pressure air duct 9 is provided at the outlet of the impurity removal chamber 4, and a sub-sieve tank 5 is fixed below the placement chamber 8. The inner wall is provided with a slideway 6 in a concave shape, and a sub-sieve plate 7 is embedded in the slideway 6, and a vibrating motor 17 is fixed under the sub-sieve plate 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com