Energy-saving smoke sprayer with smoke oil recovery function

An energy-saving and oil-recovery technology, which is applied in injection devices, liquid injection devices, etc., can solve problems such as drug precipitation, safety hazards, and impact on use efficiency, and achieve the effects of reducing precipitation, reducing pressure, and facilitating handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

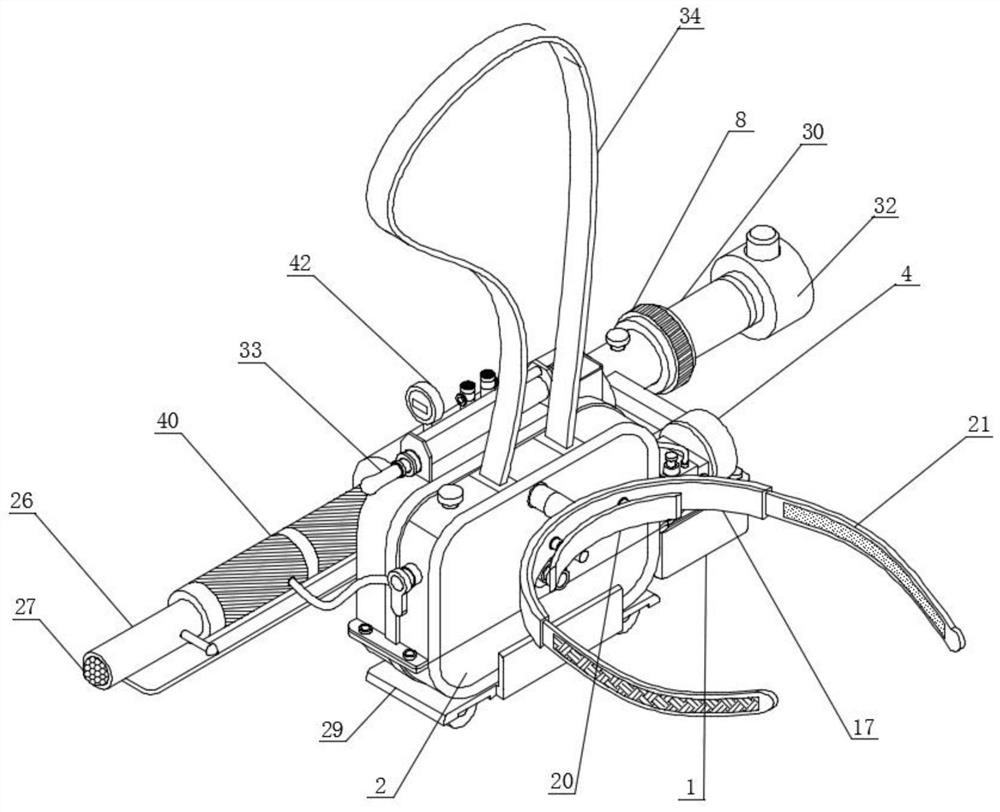

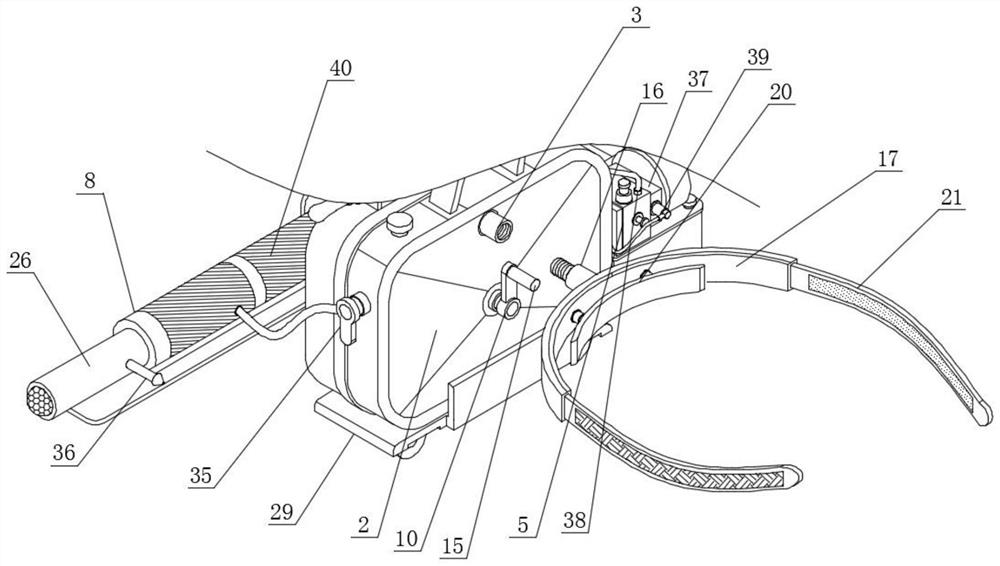

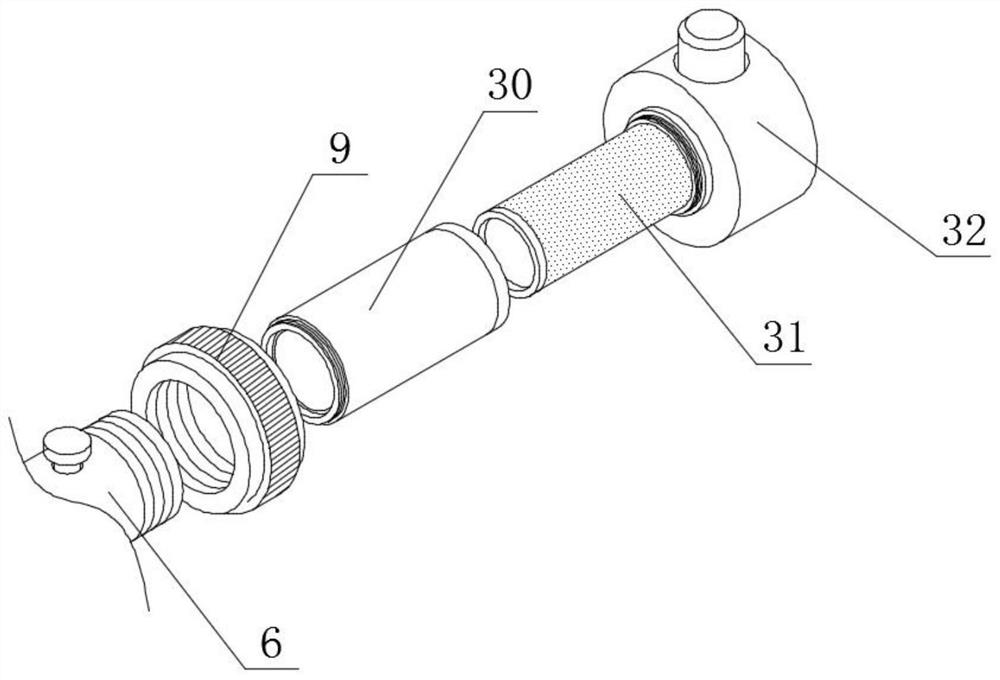

[0042] see Figure 1-4 and Figure 8 , an embodiment provided by the present invention: an energy-saving fog machine with smoke oil recovery, including a fuel tank 1, an oil pump 5 and a mounting seat 9, a medicine box 2 is installed on one side of the fuel tank 1, and the front of the medicine box 2 The top is provided with a connecting seat 3, one side of the top of the fuel tank 1 is provided with an intake valve 4, the other side of the top of the fuel tank 1 is provided with an oil pump 5, and the inner side of the intake valve 4 and the oil pump 5 is provided with a carburetor 37. The top of the carburetor 37 is provided with an inflation check valve 38, the front of the carburetor 37 is provided with an ignition rod 39, the surface of the oil pump 5 is provided with an oil quantity regulating valve, the top of the fuel tank 1 is provided with an oil filling port, and the output end of the oil pump 5 is provided with There is an oil delivery pipe, the output end of the ...

Embodiment 2

[0045] see figure 1 , figure 2 and Figure 5 , an embodiment provided by the present invention: an energy-saving fog machine with smoke oil recovery, including a medicine box 2, a limit rotating rod 10 and a supporting plate 29, a rotating seat is installed on the front of the medicine box 2, and the rotation The inside of the seat is fitted with the limited rotating rod 10, and the limited rotating rod 10 runs through the front of the medicine box 2. The bottom of the medicine box 2 is plugged with a limited seat 28, and the bottom of the limited seat 28 is connected with a supporting plate 29. , the bottom of the holding plate 29 is provided with universal wheels, the top of the holding plate 29 is provided with a clamping plate, the top of the limit seat 28 is equipped with a sealing strip, the bottom of the medicine box 2 is provided with a sealing groove, and the medicine box 2 and The front and the back of the limit seat 28 are all provided with a positioning plate, t...

Embodiment 3

[0048] see figure 1 , figure 2 , Image 6, an embodiment provided by the present invention: an energy-saving smoke machine with smoke oil recovery, including a connecting seat 3, an elastic clip 17 and a flexible pad 20, and a shoulder strap 34 is installed on the other side of the top of the medicine box 2 One side of the connection seat 3 is threadedly connected with a connecting rod 16, one side of the connecting rod 16 is provided with an elastic clip 17, one side of the elastic clip 17 is provided with a pressing rod assembly 18, and the inside of the pressing rod assembly 18 is provided with a pressing spring 19 , the front end of the pressing rod assembly 18 is connected with a flexible protective pad 20, one side of the elastic clip 17 is provided with a restraint belt 21, and the surface of the restraint belt 21 is provided with a Velcro layer;

[0049] Through the setting of the connection seat 3, the pressing rod assembly 18 and the shoulder strap 34, the limbs o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com