Resource utilization production line for stale mixed garbage and manufacturing method of resource utilization production line

A resourceful and production line technology, applied in chemical instruments and methods, recycling technology, water/sludge/sewage treatment, etc., can solve problems such as vegetation destruction, air pollution, groundwater pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

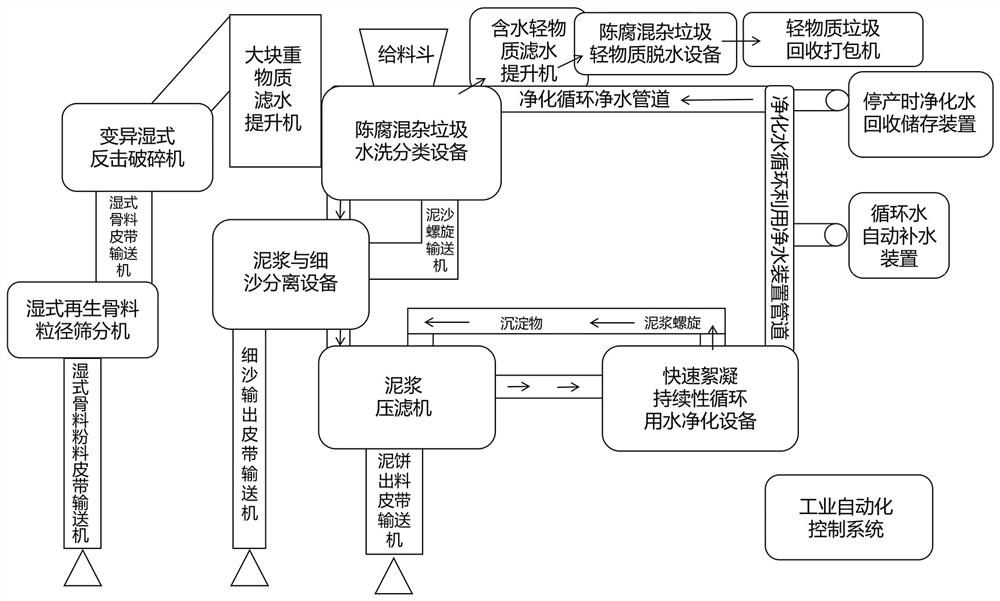

[0011] As shown in the general diagram, the production line configuration and technical route of resource utilization of stale and mixed garbage invented and created are implemented in sequence as follows:

[0012] The old and corrupt household waste, construction waste, decoration waste, underground engineering slag, and urban sludge collected in the old mixed waste landfill usually have a water content of about 30% to 80% (commonly known as wet waste). The wet garbage on the stale mixed garbage washing and sorting equipment is fed into the hopper. New patent application, invention patent application number or patent number: 202110895171.5, utility model patent application number or patent number: 292121815504.0) classify rotten mixed garbage into four categories: water-containing light substances, water-containing heavy substances, fine sand, and mud.

[0013] The technical route of the first category is: 2. Water-containing light materials are filtered and lifted by the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com