Positioning transfer device

A transfer device and positioning mechanism technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of large space occupied by the positioning transfer device, winding of outgoing lines, heavy weight, etc., to reduce equipment capital investment, The effect of preventing wire entanglement and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

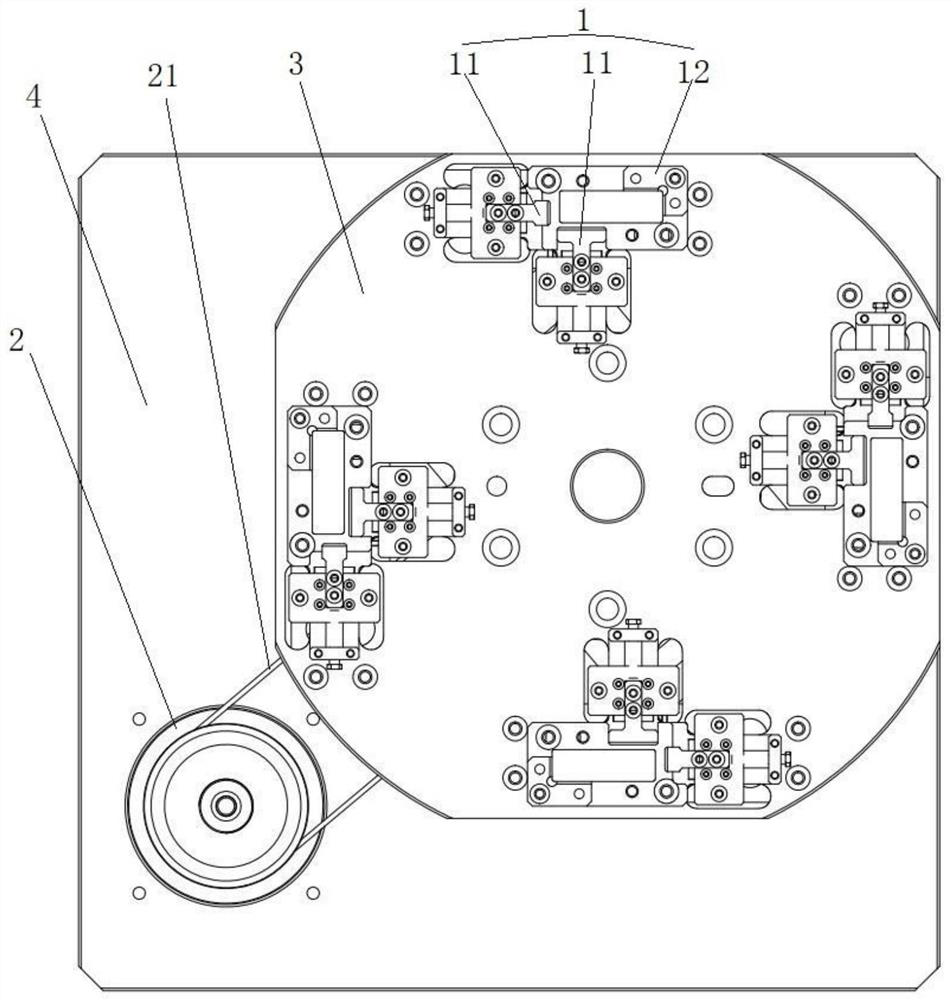

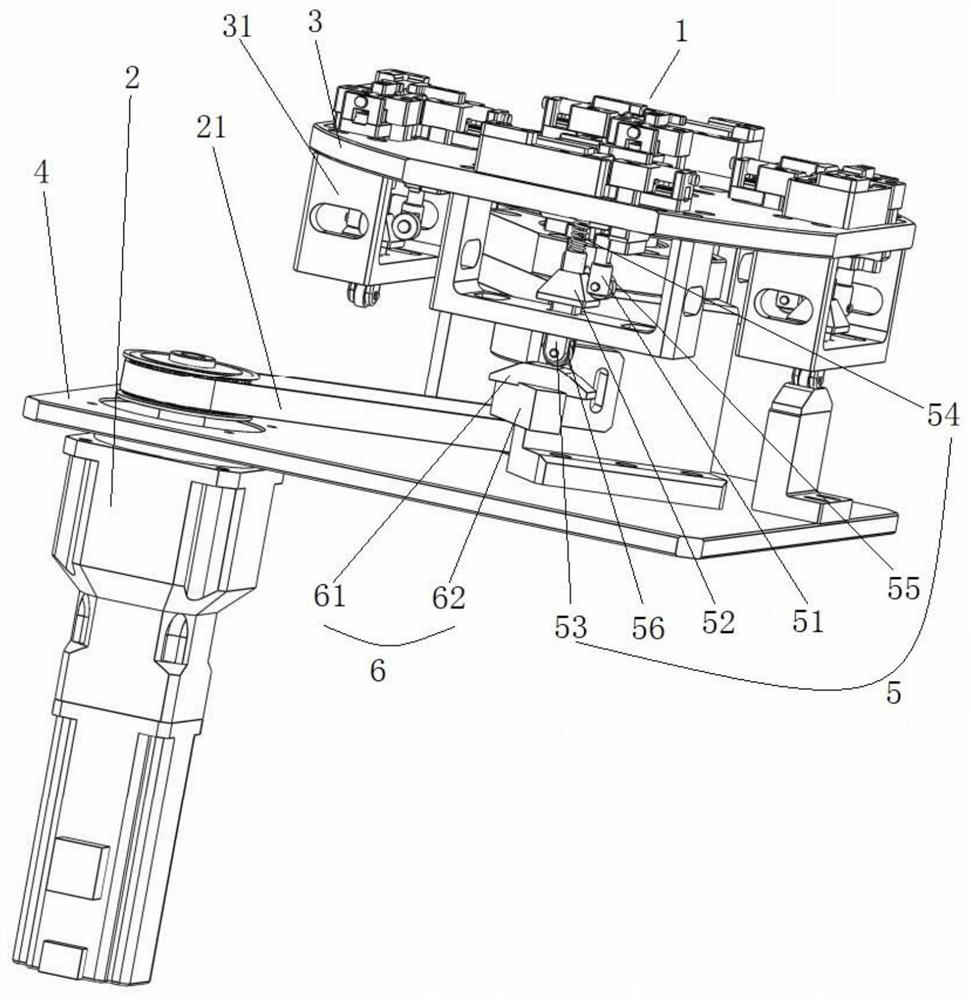

[0035] see figure 1 and figure 2 , as shown in the legend therein, a positioning transfer device includes a positioning mechanism 1 for positioning products and a power device 2 for driving the positioning mechanism 1 through the loading and unloading stations and non-loading and unloading stations. The positioning mechanism 1 Installed on a transition support plate 3, the transition support plate 3 is connected to the power output end of the power equipment 2, the fuselage of the power equipment 2 is installed on a fixed frame 4, and the positioning mechanism 1 includes movable activities relative to the transition support plate 3 The clamping block 11 and the clamping reset part (not shown in the figure) that drive the movable clamping block 11 to clamp the product,

[0036] The positioning mechanism 1 is correspondingly provided with a first linkage mechanism 5 for moving the movable clamping block 11, and a second linkage mechanism 6 for cooperating with the first linkag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com