Method for improving abnormal sound of automobile parking motor gear box

A gear box and parking technology, which is applied to surface polishing machine tools, machine tools suitable for grinding the edge of workpieces, grinding machines, etc., can solve the problems of affecting the meshing accuracy of gears, generating abnormal sound and noise, and inconvenient sharp burrs, etc. Achieve good practicality, improve abnormal noise, and improve meshing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

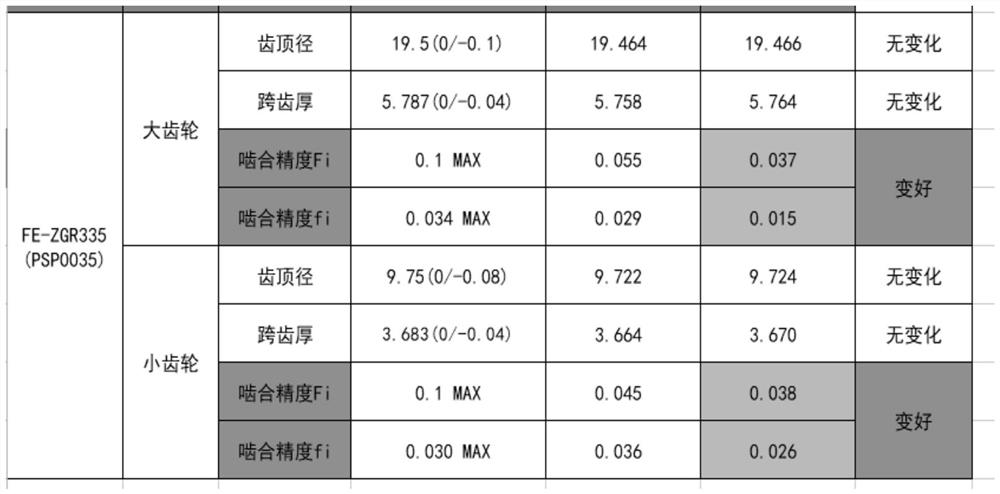

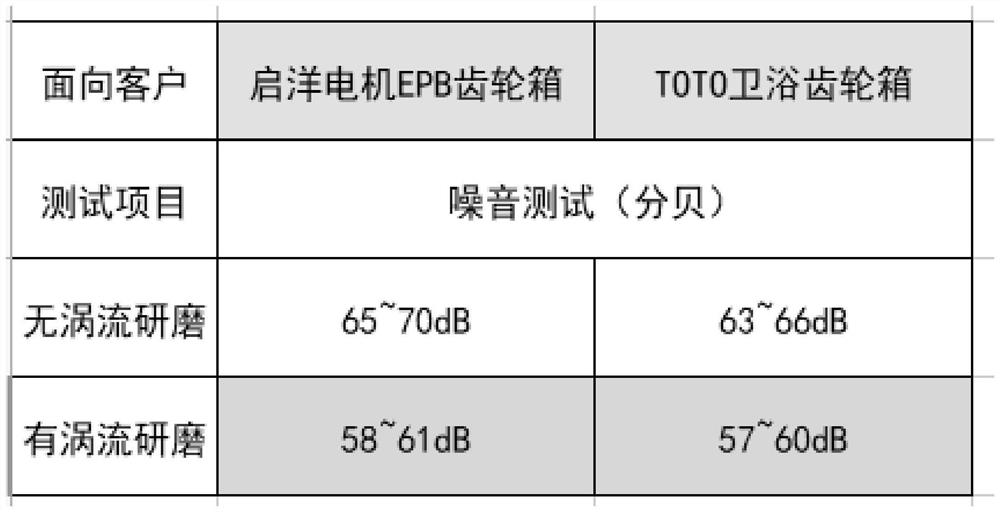

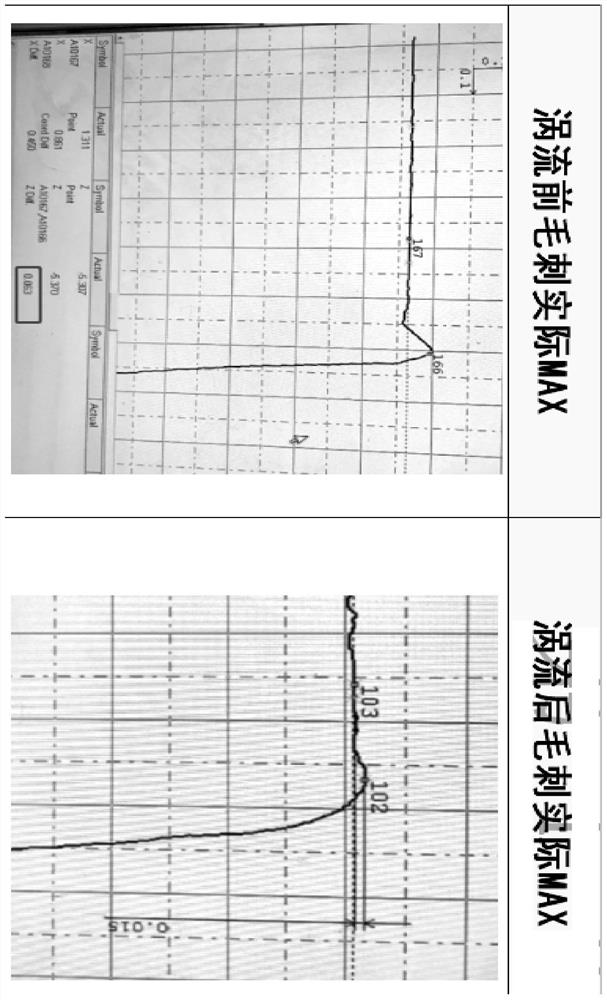

[0023] In this implementation, the motor motor teeth of the model: FE-ZGR335 are selected for operation, and the motor motor teeth of the model: FE-ZGR335 are ground by the eddy current grinder, and the burrs on the top of the sharp teeth of the motor motor teeth are rounded and smooth. Smooth, the burr height is reduced by 0.04-0.08mm; specifically include the following steps:

[0024] 1) Prepare the vortex grinder and check that all aspects of the vortex grinder are in good condition;

[0025] 2) According to the capacity of the vortex grinder, prepare anti-rust water, abrasive, water and grinding stone in proportion; and the grinding stone can be set to 6*6mm corundum grinding stone or 6*6mm corundum triangular stone ; In this embodiment, 6*6mm corundum triangular stone is selected; and the ratio of antirust water, abrasive and water is set to 1:1:40, and the antirust water and abrasive are both existing technologies, and both use Hengxin Antirust water and abrasives produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com