Multi-color printing method for towel sample and used printing sample weaving machine

A printing method and technology for small prototypes, applied in dyeing method, printing machine, rotary printing machine, etc., can solve the problems of heavy workload of technicians, large influence of manual squeegee by operators, and consistent printing effect of machines. Achieve the effect of reducing floor space and equipment investment costs, reducing product repeated proofing and dropping, and facilitating lofting and sampling operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) Make a printing sample screen, and engrave 7 strip-shaped color sample printing patterns vertically side by side on the screen according to the number of sample colors to be printed; the width of each color sample printing pattern is 4cm, and the length is 13cm; the distance between adjacent color sample printing patterns is 4cm.

[0055] (2) Use the Datacolor automatic dripping system to prepare various paint dye pastes that need to be proofed; 100ml for each color, stir evenly and set aside.

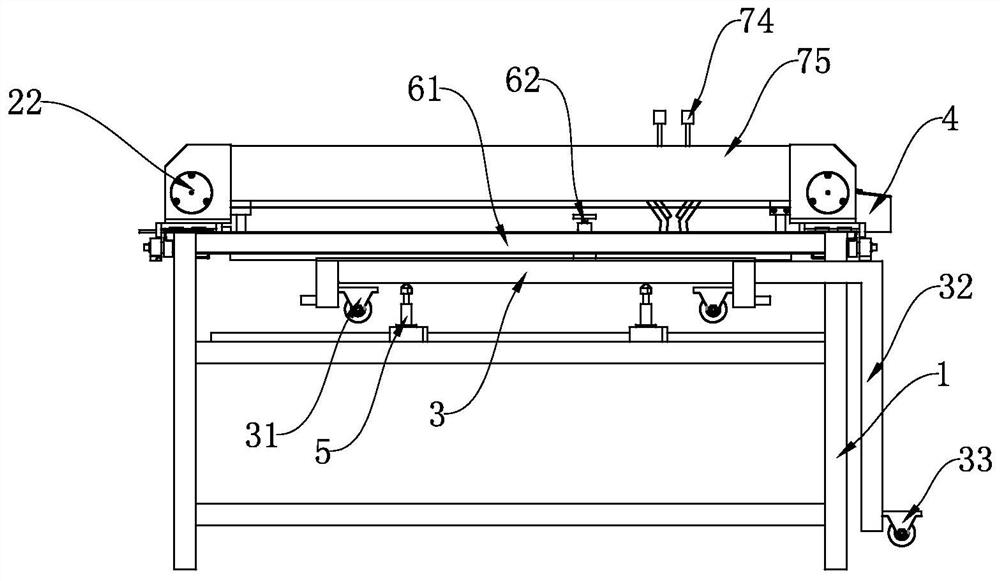

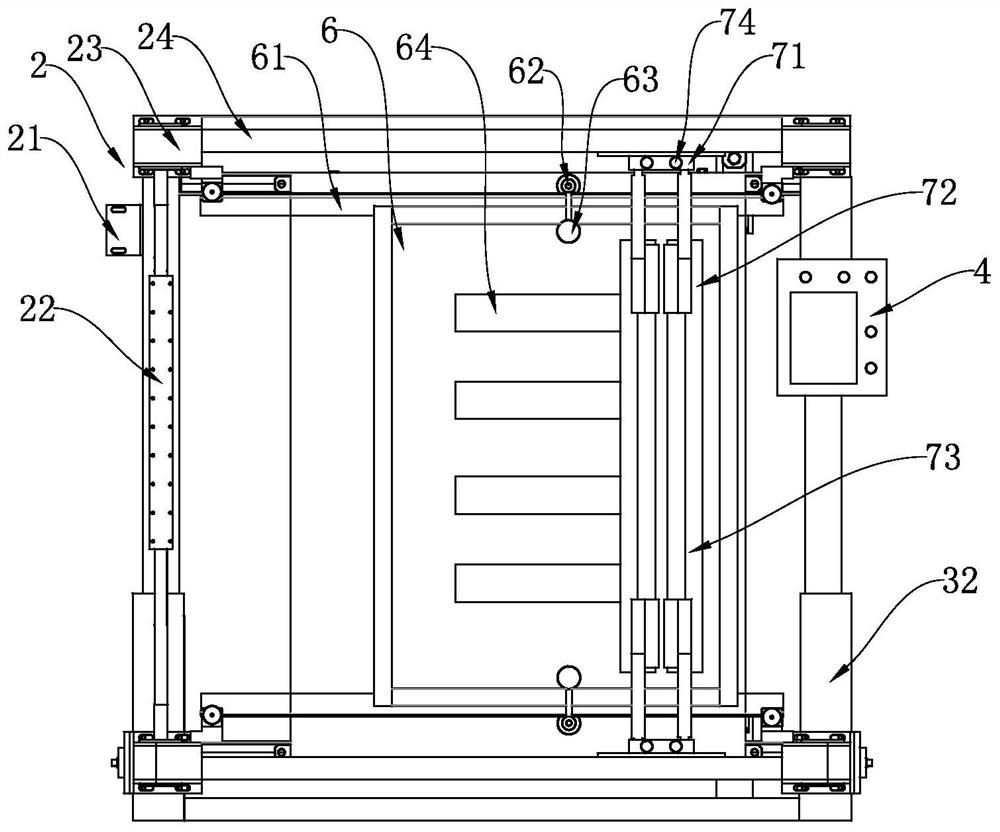

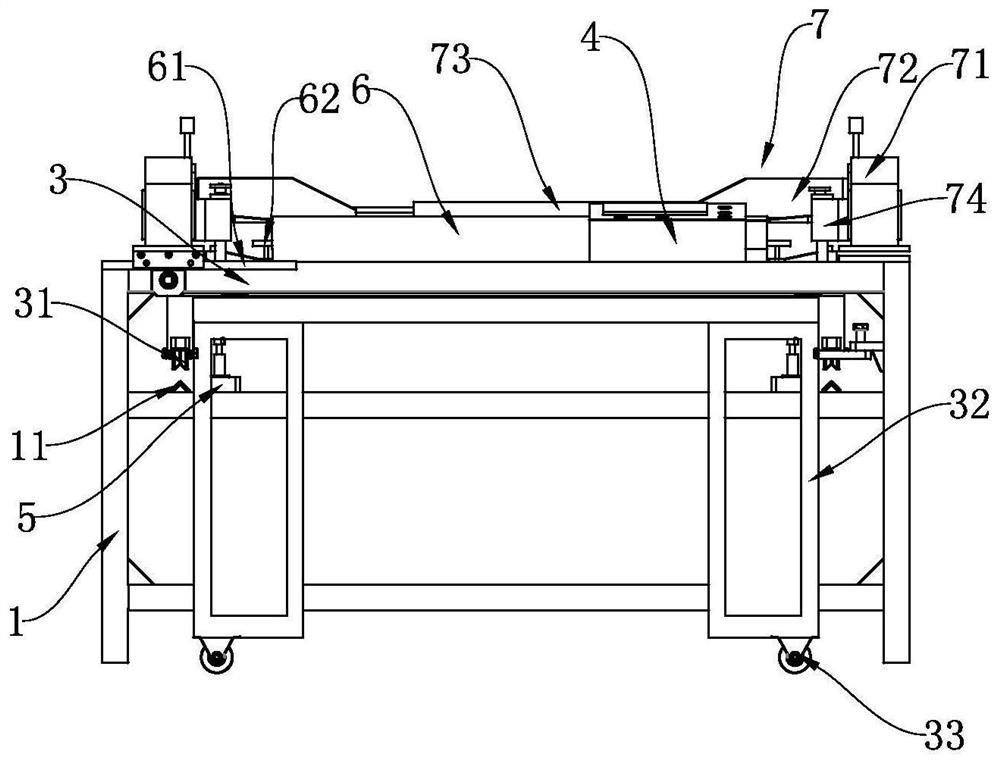

[0056] (3) The towel used for proofing is selected from the same gray fabric as the large-scale production line: pure cotton 100% terry cloth, 65cmX20cm; weight: 310g / m 2 . On the lift-type printing table of the small scraper printing prototype, pull the floor trolley to pull out the lift-type operation table, spread the towel for proofing flat, then push the floor trolley in, and install the printing sample screen on the towel ;Tighten the screw on the pressure plate, the...

Embodiment 2

[0061] (1) Make a printing sample screen, and engrave 8 strip-shaped color sample printing patterns vertically side by side on the screen according to the number of sample colors to be printed; the width of each color sample printing pattern is 4cm, and the length is 16cm; the distance between adjacent color sample printing patterns is 3.5cm.

[0062] (2) Use the Datacolor automatic dripping system to prepare various reactive dye pastes that need to be proofed; 100ml for each color, stir evenly and set aside.

[0063] (3) The towel used for proofing is selected from the same gray fabric as the large-scale production line: pure cotton 100% terry cloth, 65cmX20cm; weight: 310g / m 2 . On the lift-type printing table of the small scraper-type printing prototype, pull the floor trolley to pull out the lift-type operation table, spread the towel for proofing flat, then push the floor trolley in, and install the printing sample screen on the towel ;Tighten the screw on the pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap