High-refraction and high-dispersion optical glass

An optical glass, high dispersion technology, applied in optics, optical components, instruments, etc., can solve the problems of glass thermal shock resistance deterioration, large thermal expansion coefficient, cracking, etc., to achieve high refractive index and dispersion, low thermal expansion The effect of the coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0133]

[0134] In order to further clearly illustrate and illustrate the technical solution of the present invention, the following non-limiting examples are provided.

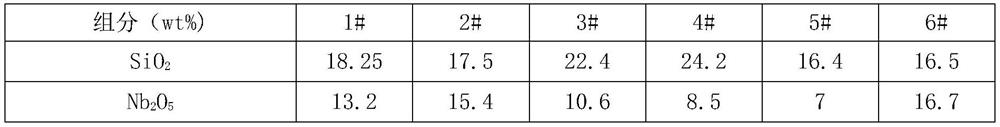

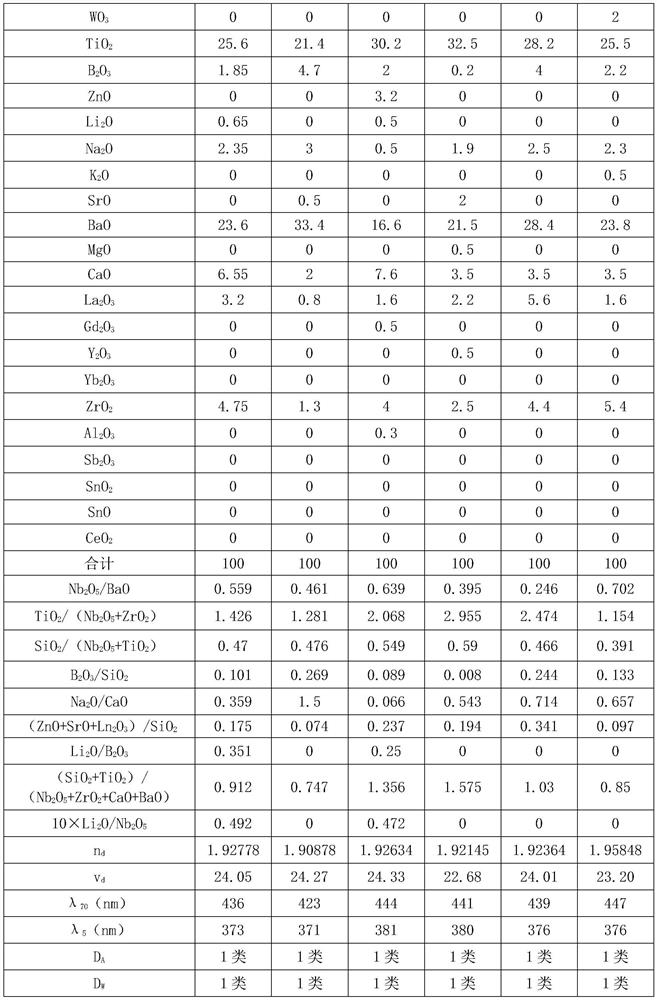

[0135] In this embodiment, the high-refraction and high-dispersion optical glass having the compositions shown in Table 1 to Table 3 was obtained by adopting the above-mentioned manufacturing method of high-refraction and high-dispersion optical glass. In addition, the properties of each glass were measured by the test method described in the present invention, and the measurement results are shown in Tables 1 to 3. In the anti-devitrification performance test of the secondary pressure type in Table 1 to Table 3, according to the aforementioned test method, the glass with no opacification and no crystal particles on the surface and inside is recorded as "A", and the glass has no opacification and no devitrification inside However, there are crystal grains on the surface, which is recorded as "B" (the crysta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com