Moisture-resistant putty and preparation method thereof

A putty and moisture-resistant technology, applied in the direction of filling slurry, etc., can solve the problems of grinding delamination, easy powder falling, poor strength, etc., and achieve the effect of not easy to fall powder, easy to operate and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

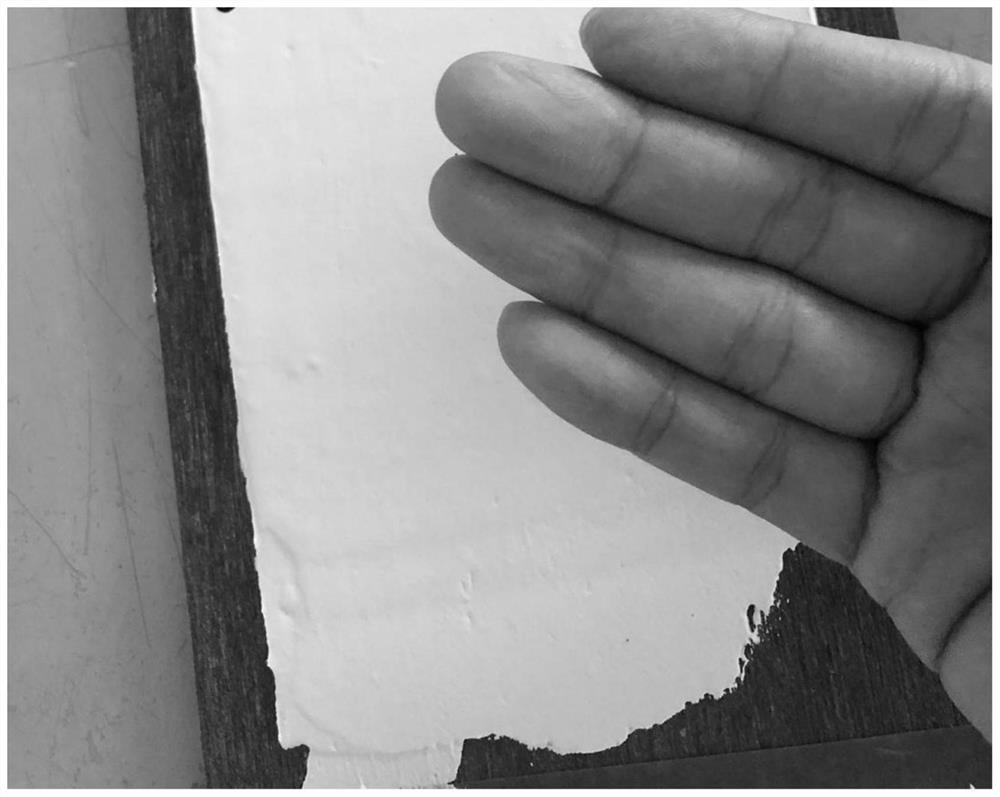

Image

Examples

Embodiment 1

[0045] A kind of moisture-resistant putty of the present invention comprises following putty puree:

[0046] The putty puree is prepared from the following components according to the following ratios in parts by weight:

[0047]

[0048]

[0049] The redispersible latex powder is selected from redispersible latex powder with a film forming temperature of 4°C.

[0050] The heavy calcium is 350-450 mesh heavy calcium.

[0051] The white cement is 325 white cement.

[0052] The moisture-resistant putty is prepared by mixing putty stock and water at a ratio of 1:0.3 in parts by weight.

[0053] The redispersible latex powder adopts Corning 60M type redispersible latex powder.

[0054] The preparation method of described putty puree mainly comprises the following steps carried out in sequence:

[0055] Start the disperser, adjust the dispersing speed to 500 rpm, mix white cement, heavy calcium, cellulose ether, starch ether, redispersible latex powder, and early strength...

Embodiment 2

[0058] A kind of moisture-resistant putty of the present invention comprises following putty puree:

[0059] The putty puree is prepared from the following components according to the following ratios in parts by weight:

[0060]

[0061] The redispersible latex powder is selected from redispersible latex powder with a film forming temperature of 0°C.

[0062] The heavy calcium is 350-450 mesh heavy calcium.

[0063] The white cement is 325 white cement.

[0064] The moisture-resistant putty is prepared by mixing putty stock and water at a ratio of parts by weight of 1:0.35 during use.

[0065]The redispersible latex powder adopts Corning 60M type redispersible latex powder.

[0066] The preparation method of described putty puree mainly comprises the following steps carried out in sequence:

[0067] Start the disperser, adjust the dispersing speed to 500 rpm, mix white cement, heavy calcium, cellulose ether, starch ether, redispersible latex powder, and early strength ...

Embodiment 3

[0070] A kind of moisture-resistant putty of the present invention comprises following putty puree:

[0071] The putty puree is prepared from the following components according to the following ratios in parts by weight:

[0072]

[0073] The redispersible latex powder is selected from redispersible latex powder with a film forming temperature of 10°C.

[0074] The heavy calcium is 350-450 mesh heavy calcium.

[0075] The white cement is 325 white cement.

[0076] The moisture-resistant putty is prepared by mixing putty stock and water at a ratio of parts by weight of 1:0.25 during use.

[0077] The redispersible latex powder adopts Corning 60M type redispersible latex powder.

[0078] The preparation method of described putty puree mainly comprises the following steps carried out in sequence:

[0079] Start the disperser, adjust the dispersing speed to 600 rpm, mix white cement, heavy calcium, cellulose ether, starch ether, redispersible latex powder, and early strengt...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap