Chemical fiber filament twisting and winding integrated device and using method

A filament and chemical fiber technology is applied in the field of chemical fiber filament twisting and winding integrated devices, which can solve the problems of high energy consumption, workshop logistics handling, destruction of production continuity, and increase of production costs, etc. Large space and smooth overall operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

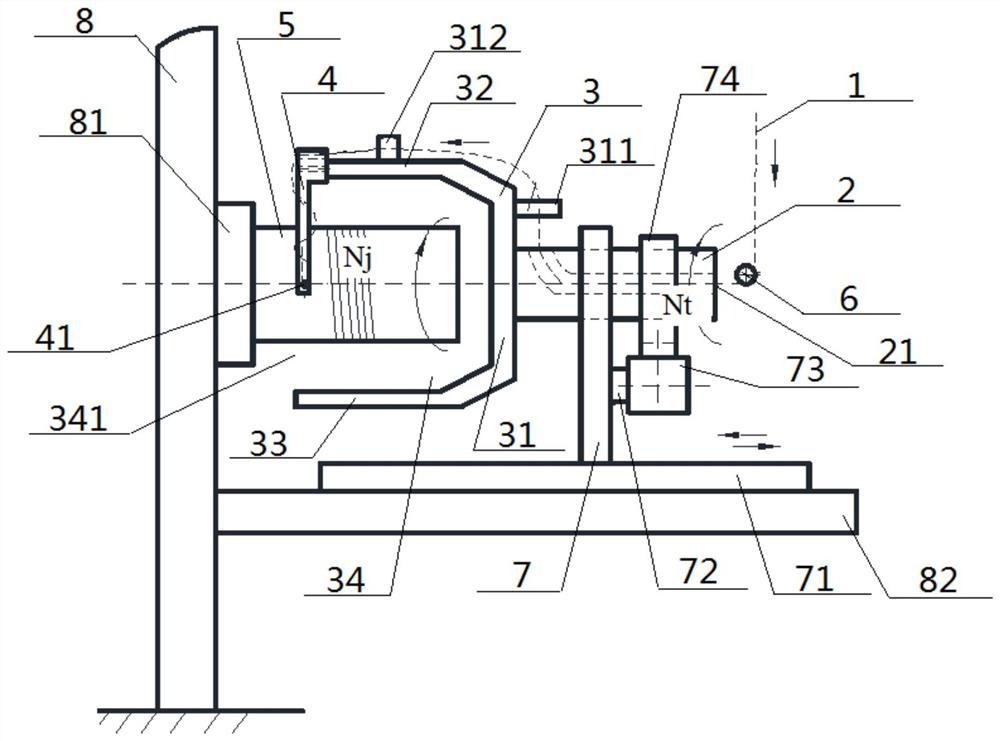

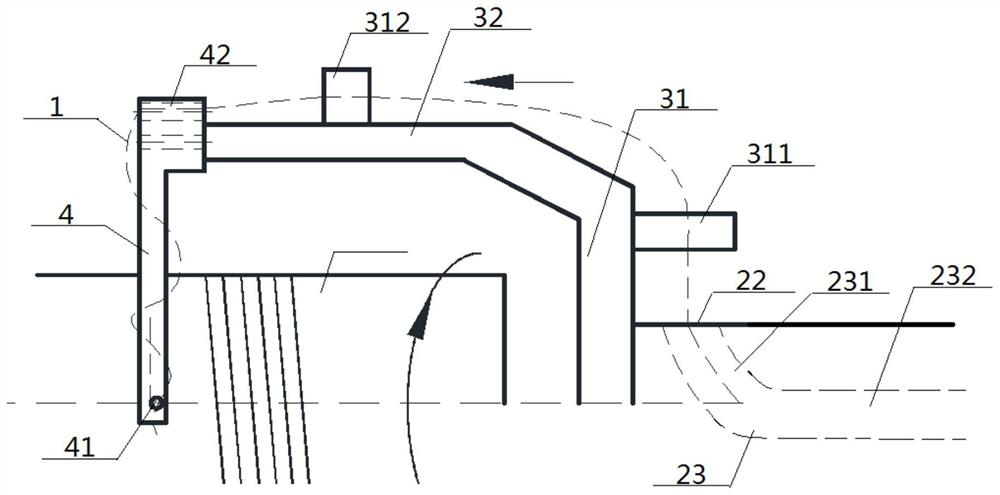

[0047] see figure 1 — Figure 8 , an integrated twisting and winding device for chemical fiber filaments, including a rotor 2, a twisting frame 3, a guide rod 4 and a wire drum 5, and the twisting frame 3 includes a driving rod 31, a screw rod 32 and an auxiliary rod 33. The two ends of the driving rod 31 are respectively connected with the inner ends of the screw rod 32 and the auxiliary rod 33, and the driving rod 31, the screw rod 32 and the auxiliary rod 33 enclose a frame inner cavity 34 with one-way opening , the inside of the frame cavity 34 is provided with one end of the wire tube 5, and the other end of the fiber tube 5 extends to the outside of the frame cavity 34 after passing through the cavity opening 341 of the frame cavity 34, and the middle part of the drive rod 31 The outer surface is connected with the inner end of the rotor 2, and the outer end of the rotor 2 extends outwards, and one end of the wire drum 5 is arranged opposite to the inner end of the roto...

Embodiment 2

[0050] Basic content is the same as embodiment 1, the difference is:

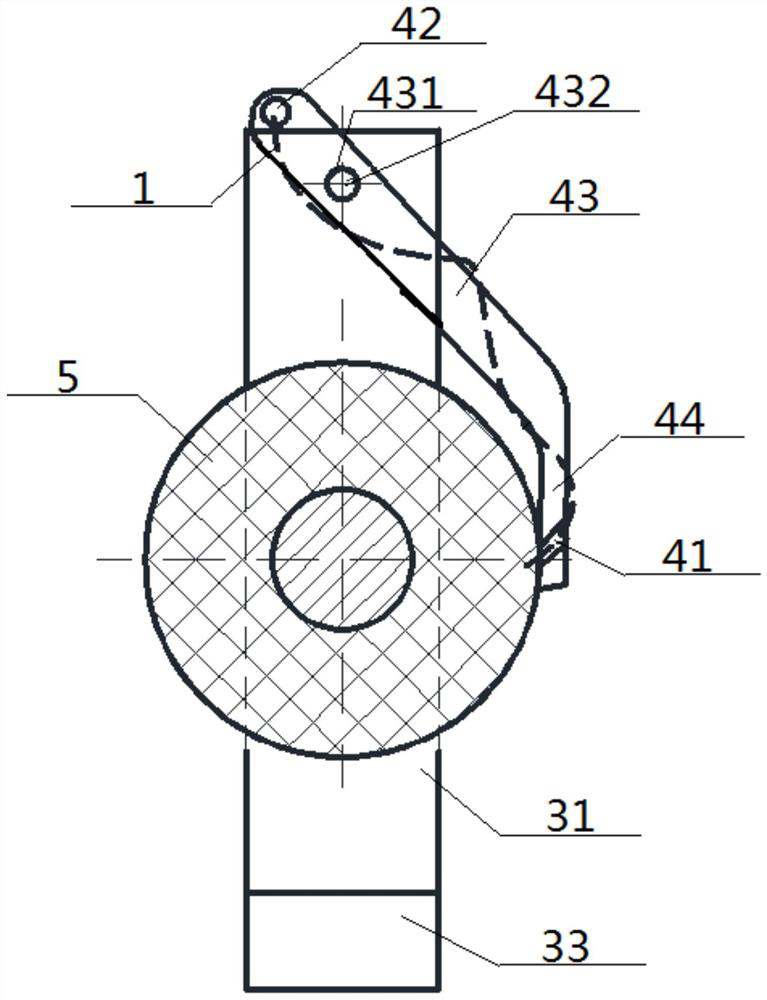

[0051] The guide wire rod 4 includes a guide wire upper rod 43 and a guide wire lower rod 44, and a hinge hole 431 is provided near the top of the guide wire upper rod 43, and the hinge hole 431 is connected with the guide wire through a pin 432. The top of bar 4 is mutually hinged, and the bottom end of guide wire upper rod 43 is connected with the top of guide wire lower rod 44, and the bottom end of guide wire lower rod 44 rides on the side encirclement of wire cylinder 5, and guide wire lower rod 44 A tube-near guide wire hole 41 is opened near the bottom end thereof, and the tube-near guide wire hole 41 is in contact with the side circumference of the wire tube 5 . The top of the guide wire upper rod 43 is provided with a proximal rod guide wire hole 42 , and the hinged hole 431 is located between the proximal rod guide wire hole 42 and the bottom end of the guide wire upper rod 43 .

[0052] After th...

Embodiment 3

[0054] Basic content is the same as embodiment 1, the difference is:

[0055] Preferably, the rotation directions of the rotor 2 and the wire drum 5 are the same, and more preferably both rotate clockwise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com