Wire fixing clamp and clothes processing equipment

A wire fixing clip and wire stud technology, which is applied to other washing machines, household clothes dryers, washing devices, etc., can solve the problems of low strength of shrapnel, easy cracking, and shrapnel breaking, so as to disperse the force of the lead wire and reduce the risk of breaking , the effect of reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

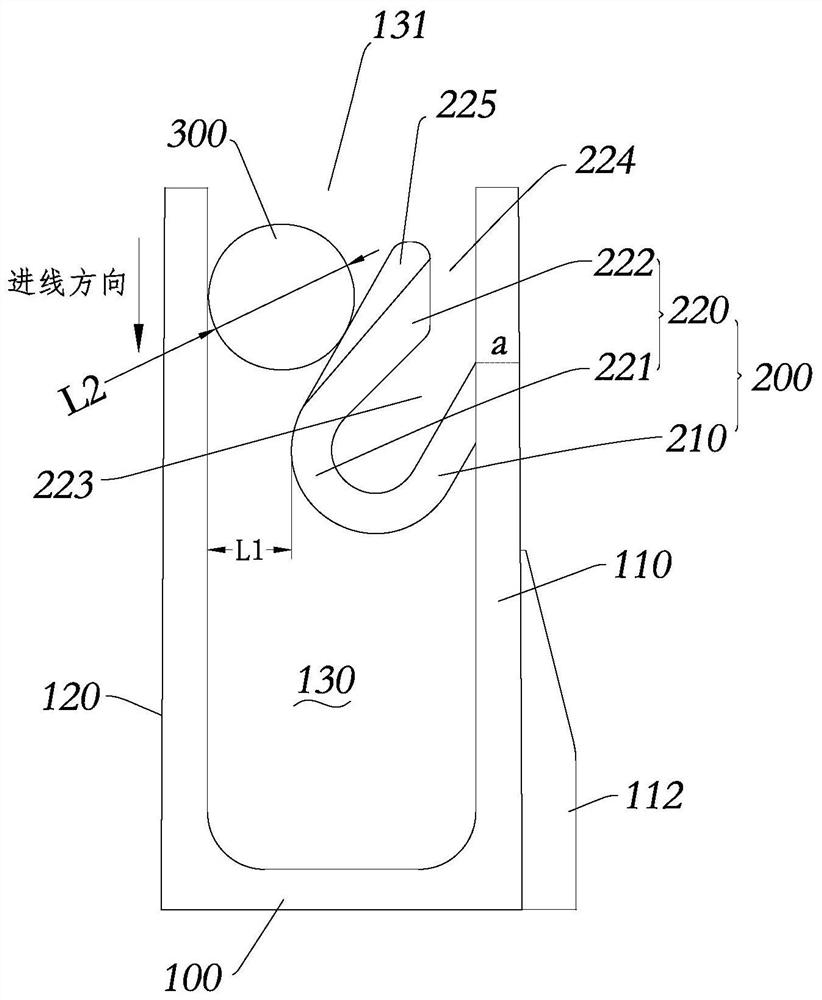

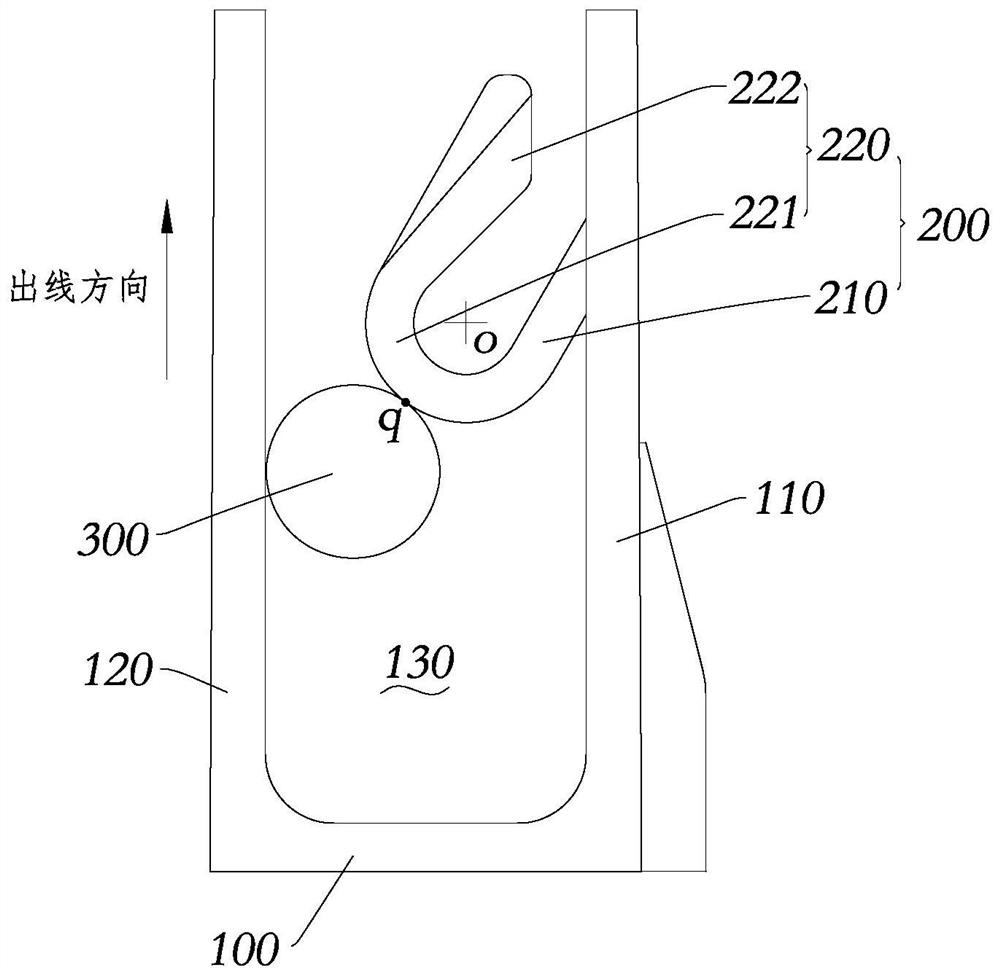

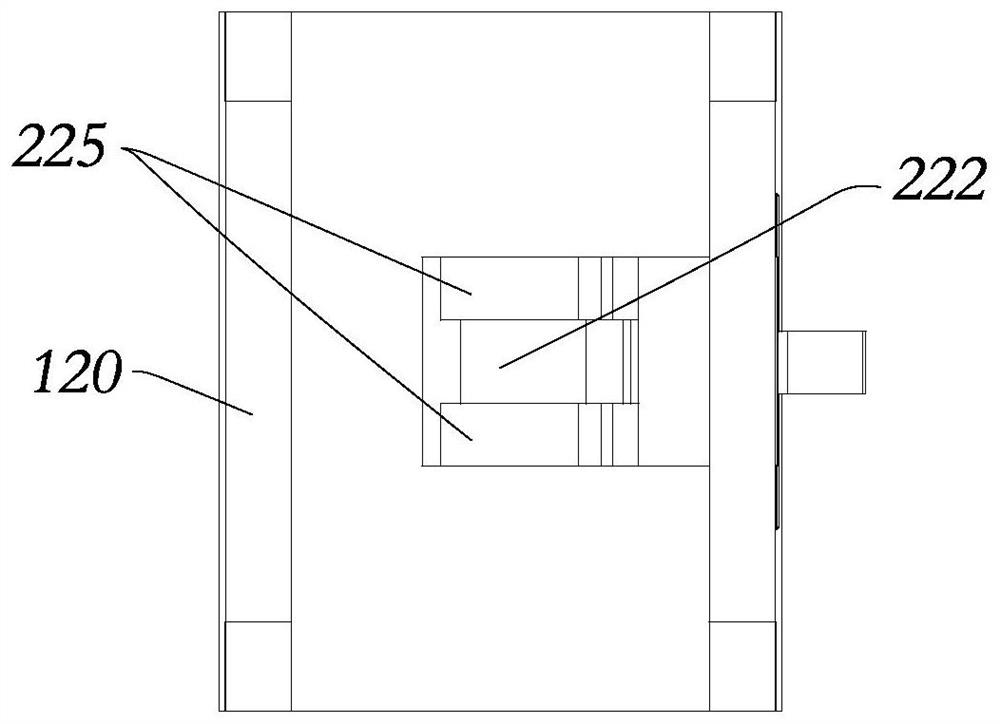

[0044] The wire fixing clip proposed by the present invention includes: a base having a first wire fixing post and a second wire fixing post oppositely arranged, and the first wire fixing post and the second wire fixing post are on the base A wire slot is defined, and a limit buckle arranged inside the first wire fixing post and used to limit the lead wire in the wire slot; wherein, the limit buckle includes a first buckle arm and a second buckle arm, the first buckle arm is fixed on the inner side of the first wire fixing column and extends toward the bottom of the wire slot, and the second buckle arm is formed by the first buckle arm The end portion extends toward the opening direction of the wire holding slot, and a wire passing channel is formed between the second buckle arm and the second wire fixing post. The present invention optimizes the limit buckle structure used to limit the lead wires in the wire slot, increases the mechanical strength of the limit buckle, and als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com