Self-circulation cooling honeycomb seat structure

A honeycomb seat and honeycomb technology, applied in the direction of leakage prevention, engine components, machines/engines, etc., can solve the problems of reducing the temperature bearing capacity of the honeycomb seat and reducing the cooling effect of the honeycomb seat, so as to improve the cooling effect, improve the temperature bearing capacity, The effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

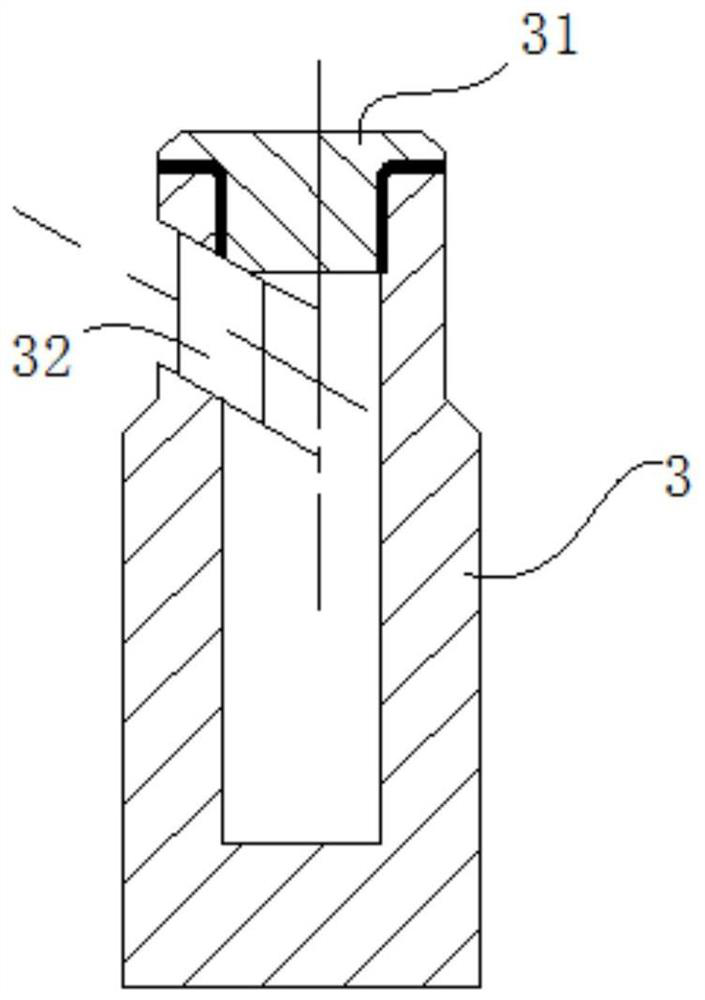

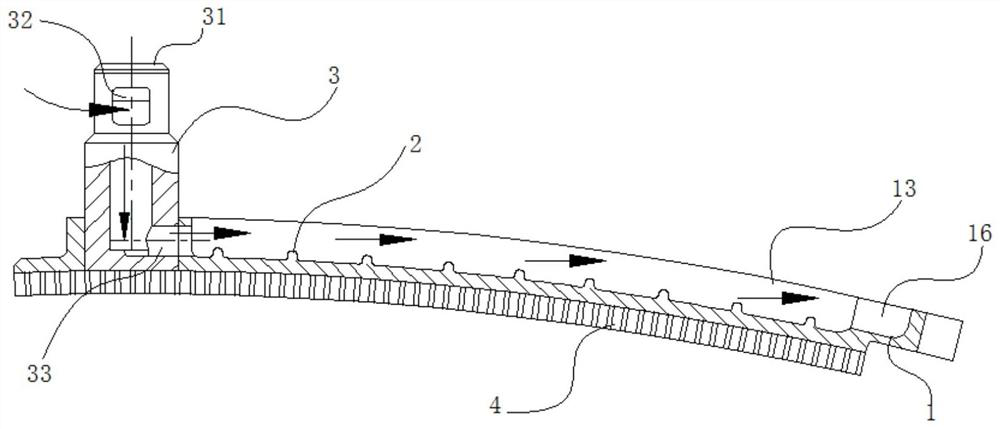

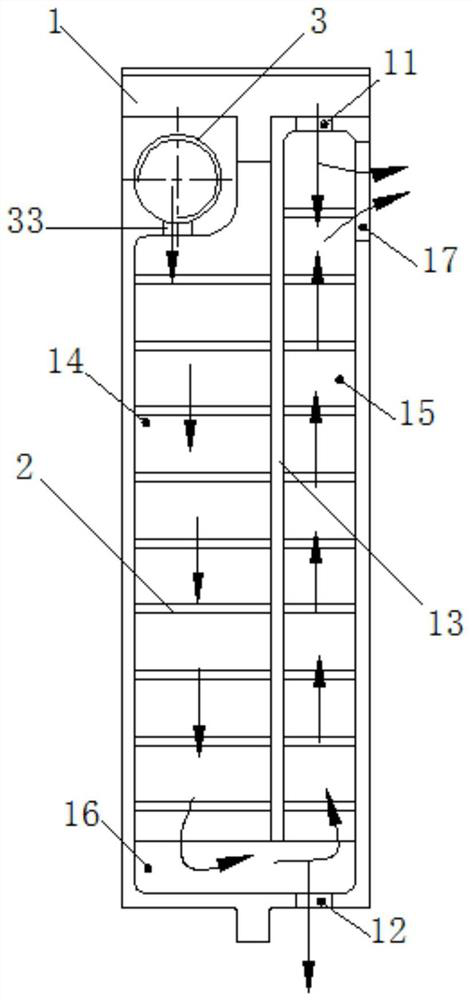

[0026] see Figure 1 to Figure 4 shown.

[0027] A self-circulating cooling honeycomb base structure of the present invention comprises:

[0028] The seat body 1 of the honeycomb seat;

[0029] Casting forms a plurality of ribs 2 distributed at intervals on the bottom surface of the top groove of the seat body 1;

[0030] The front wall surface and the rear wall surface of the seat body 1 are respectively provided with front-end inlet grooves 11 and rear-end outlet grooves 12 for gas flow. Disturbance, thereby enhancing heat exchange and improving heat exchange efficiency, the top grooves of the seat body 1 between adjacent honeycomb seats pass through the front inlet groove 11 and the rear outlet groove 12 for gas exchange flow.

[0031] When adjacent honeycomb seats are installed, the rear end outlet groove 12 of the previous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com