Magnetic suspension bearing, motor, compressor and air conditioner

A magnetic suspension bearing and axial technology, applied in the field of magnetic suspension, can solve the problems of complex control logic, mutual interference of axial and radial control magnetic circuits, and low system stability, so as to simplify control logic, improve system stability, increase Effect of large axial loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

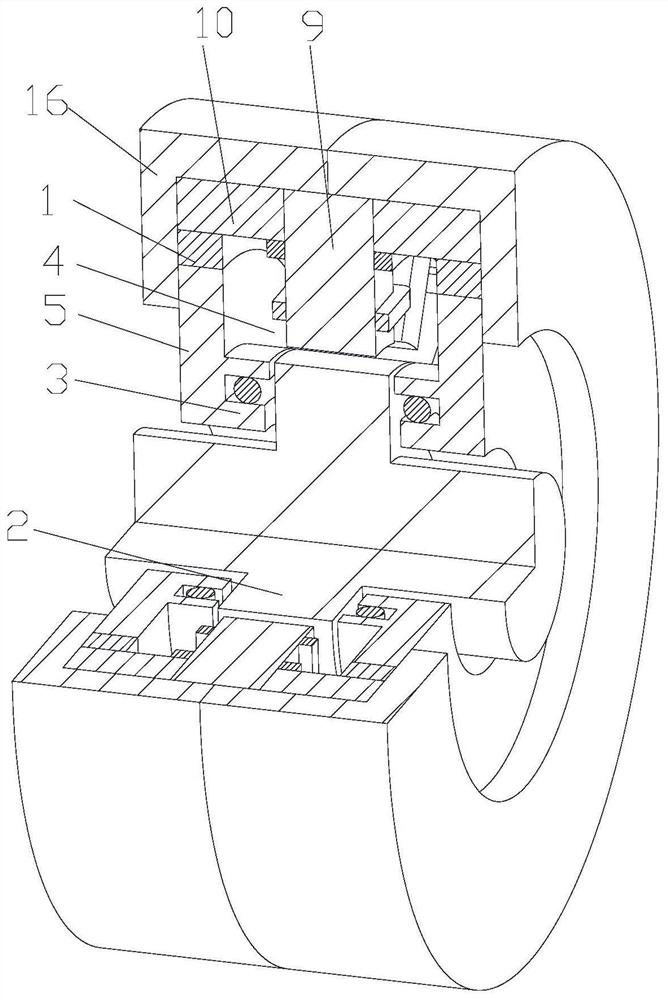

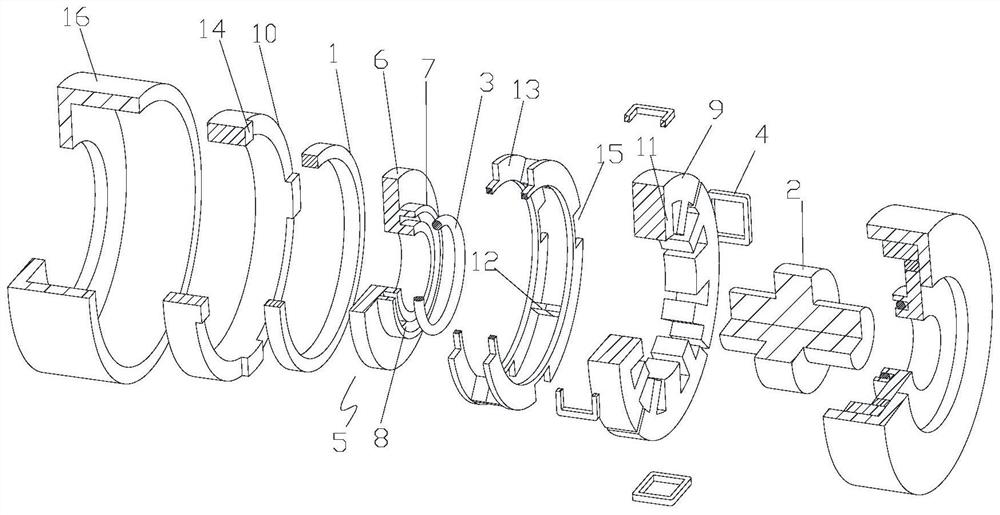

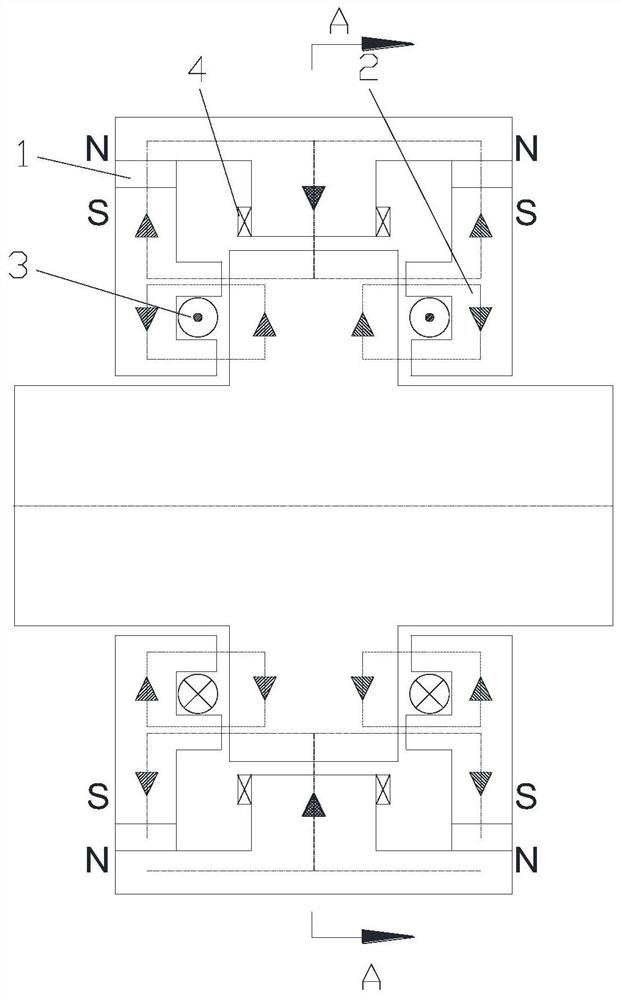

[0036] see in conjunction Figure 1 to Figure 4 As shown, according to the embodiment of the present application, the magnetic suspension bearing includes an axial magnetic field control part, a radial magnetic field control part and a rotor assembly, the two ends of the radial magnetic field control part are respectively provided with an axial magnetic field control part, and the rotor assembly includes a rotor iron Core 2, the axial magnetic field control part includes an axial control end opposite to the end face of the rotor core 2, the axial control end is provided with an axial control winding 3, and the radial magnetic field control part includes The radial control end is arranged oppositely, the radial control end is provided with a radial control winding 4, and a permanent magnet 1 is respectively arranged between the axial magnetic field control part and the radial magnetic field control part at both ends, and the permanent magnet 1 is the permanent magnet 1 The axia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com