Bolt axial stress detection method based on ultrasonic spectrum energy attenuation

A technology of axial stress and spectral energy, applied in the direction of using stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of uneven stress distribution transit time measurement, unsuitable for measuring bolt stress, etc. Achieve a wide range of applications, save costs, and reduce requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

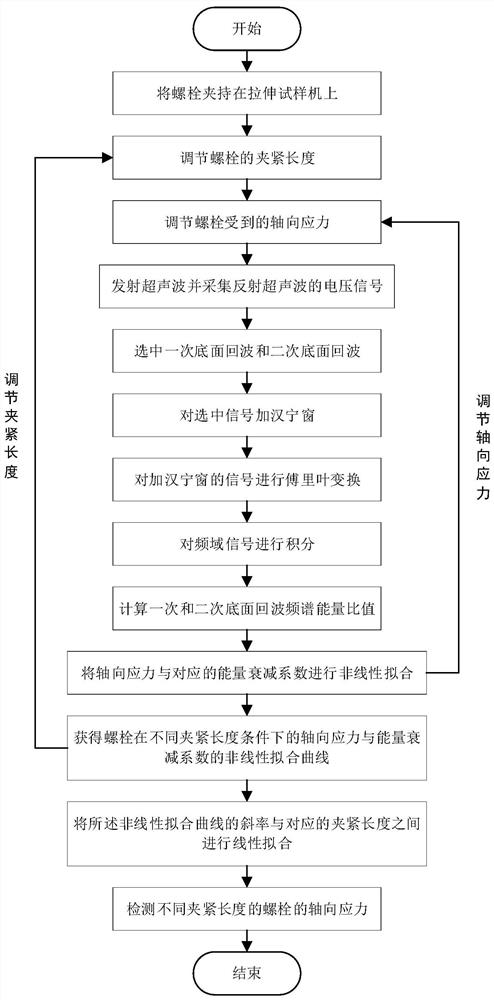

[0054] Such as figure 1 As shown, it is a flow chart of an embodiment of the bolt axial stress detection method based on ultrasonic spectrum energy attenuation in the present invention. The bolt axial stress detection method based on ultrasonic spectrum energy attenuation of the present invention comprises the following steps:

[0055] 1) Clamp the bolt on the tensile testing machine.

[0056] 2) Adjust the clamping length of the bolt with a tensile test machine.

[0057] 3) Use the tensile test machine to adjust the axial stress σ on the bolt.

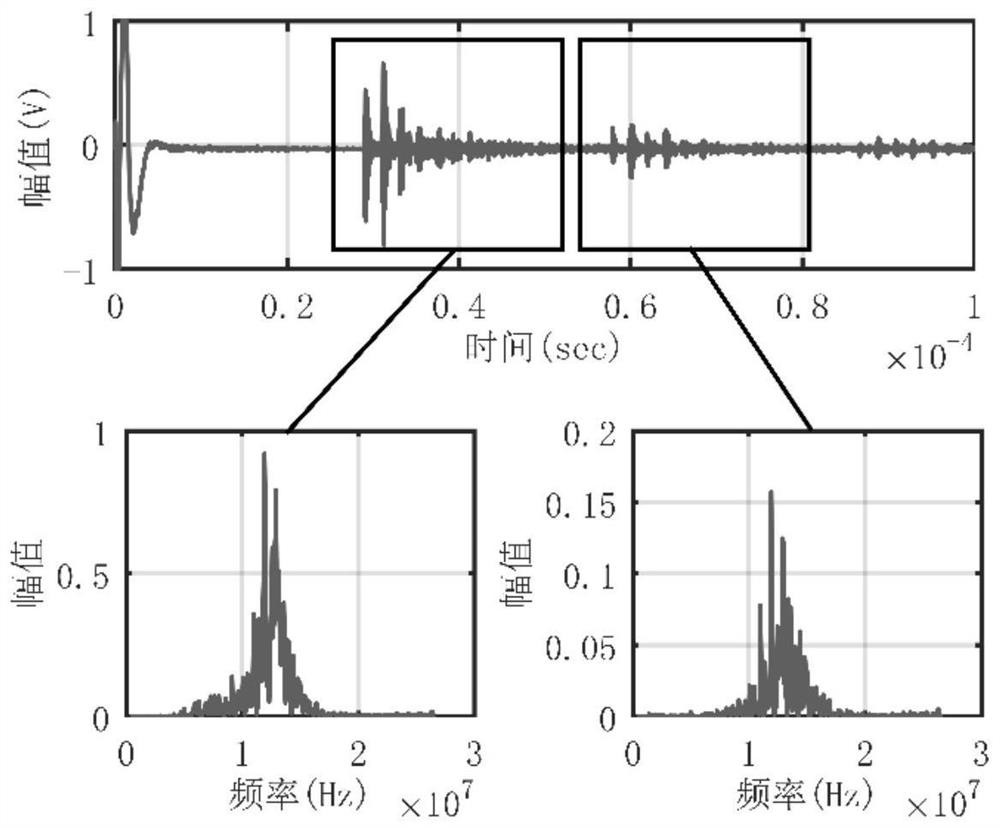

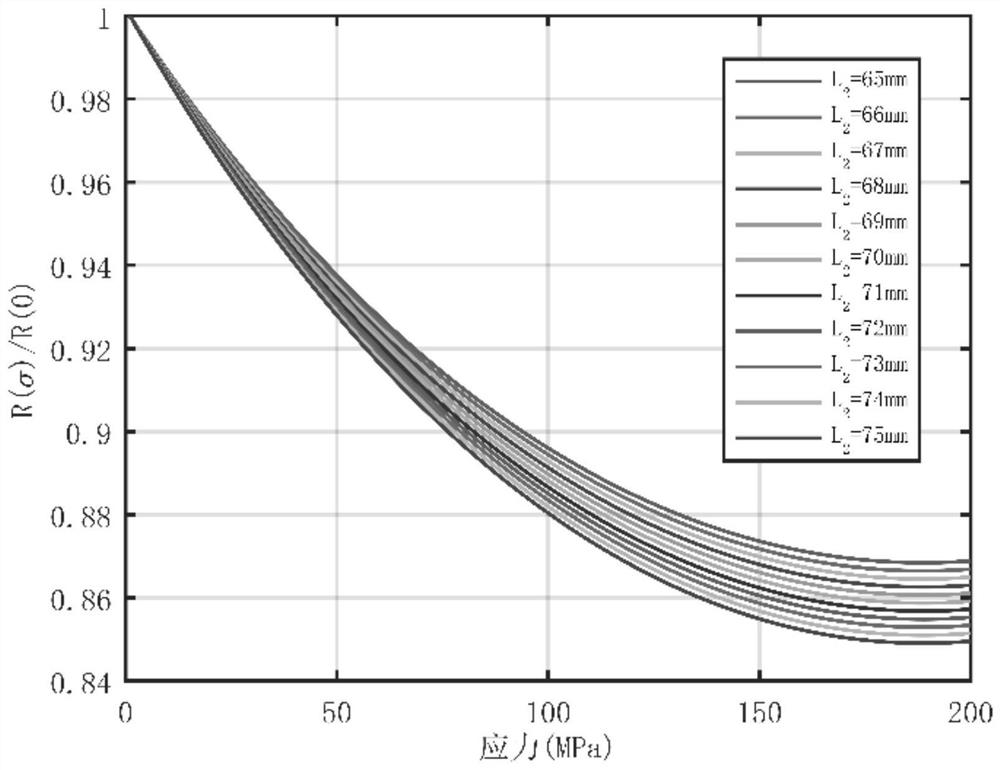

[0058] 4) An ultrasonic wave is excited on one end face of the bolt, and the voltage signal of the ultrasonic wave reflected from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com