Ripple noise test system and method

A ripple noise and test system technology, applied in the direction of noise figure or signal-to-noise ratio measurement, etc., can solve the problem that the cut-off frequency of the ripple probe cannot be switched arbitrarily, and achieve the effect of achieving scalability, improving test efficiency and reducing interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

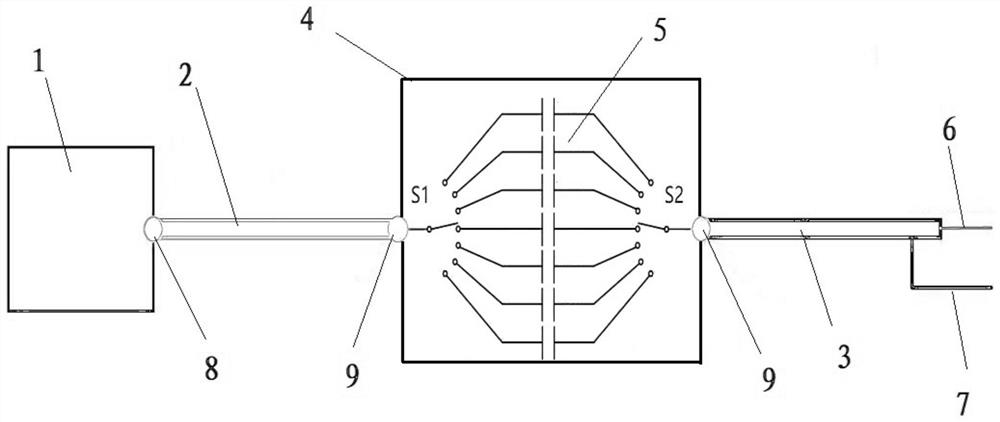

[0045] Such as figure 1 As shown, the present embodiment provides a ripple noise test system, including an oscilloscope 1, a first coaxial cable 2, a second coaxial cable 3 and a PCB board 4, and the PCB board 4 is provided with an isolation capacitance switching circuit 5 , the oscilloscope 1 is connected to the first end of the first coaxial line 2, the second end of the first coaxial line 2 is connected to the output end of the isolation capacitor switching circuit 5, and the first end of the second coaxial line 3 is connected to the isolation capacitor The input end of the switching circuit 5 is connected, and the second end of the second coaxial line 2 is provided with a ripple probe assembly.

[0046] Among them, the ripple probe assembly includes a first metal needle 6 and a second metal needle 7, the first metal needle 6 is welded on the inner core of the second coaxial line 3, and the second metal needle 7 is welded on the second coaxial line 3 on the shielding layer...

Embodiment 2

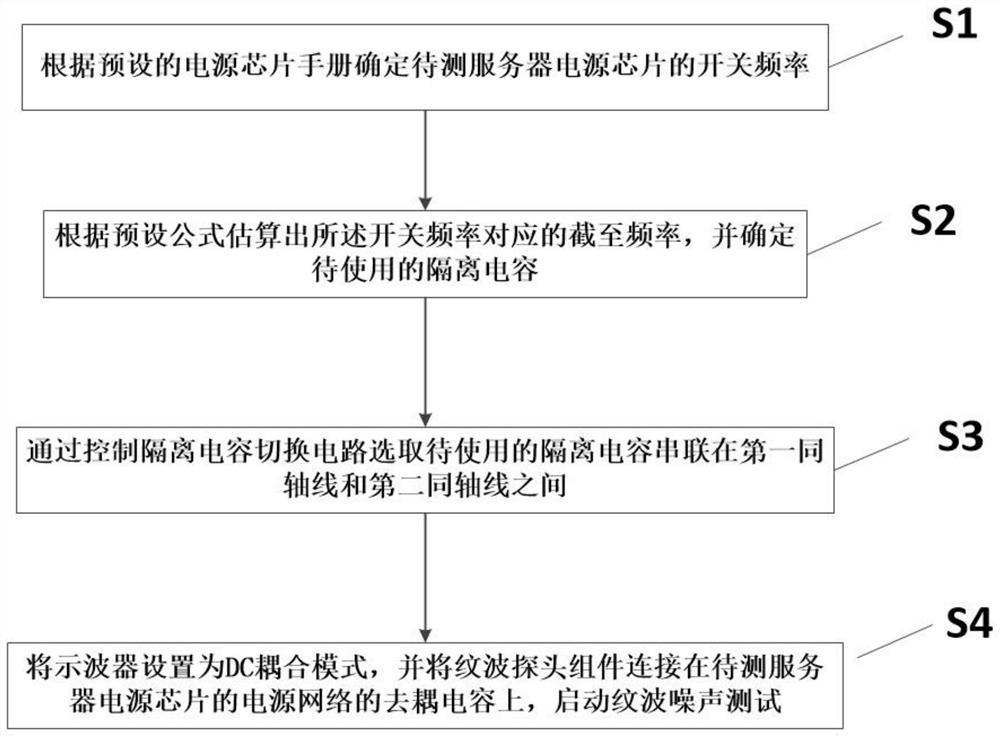

[0050] Based on Example 1, such as figure 2 As shown, the present invention also discloses a ripple noise testing method, which specifically includes the following steps:

[0051] S1: Determine the switching frequency of the server power chip to be tested according to the preset power chip manual.

[0052] S2: Estimate the cut-off frequency corresponding to the switching frequency according to a preset formula, and determine the isolation capacitor to be used.

[0053] First, estimate the cut-off frequency f corresponding to the switching frequency f according to the calculation formula of the voltage gain G of the high-pass filter L ;

[0054] The formula for calculating the voltage gain G of the high-pass filter is:

[0055] Among them, G=0.9899, which means that the measurement error is approximately equal to 1%; therefore, the switching frequency f is the cut-off frequency f L 7 times.

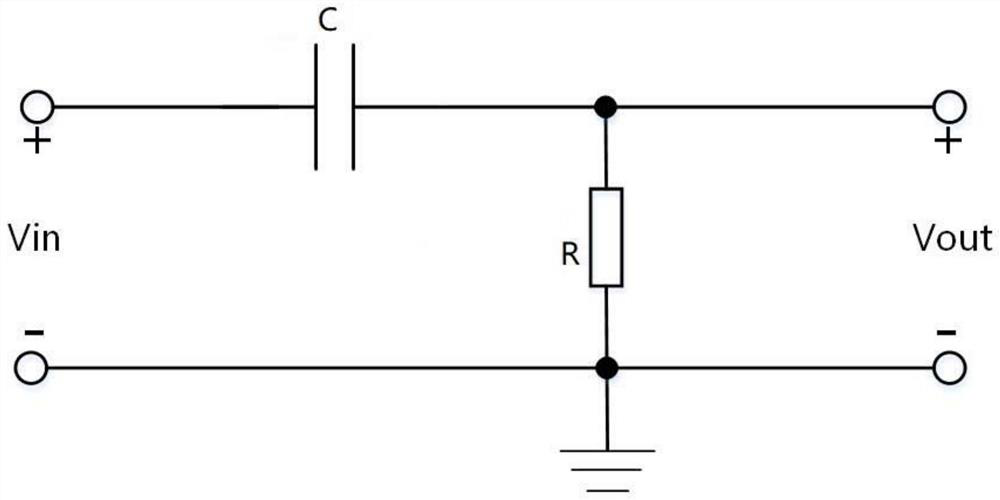

[0056] Then, according to the cut-off frequency f L The formula for determi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com