A carbon-silicon composite material and its preparation method and application

A composite material, carbon silicon technology, applied in the direction of nanotechnology for materials and surface science, active material electrodes, nanotechnology, etc., can solve the problems of poor material consistency and limited performance improvement, and achieve high consistency and reduce impedance , The preparation process is simple and easy to operate

Active Publication Date: 2022-05-31

常州烯源谷新材料科技有限公司

View PDF14 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In the prior art, silicon-carbon materials are modified by doping different elements, but this kind of doping is generally completed by simple mixing with silicon-carbon materials, the consistency of the materials is poor, and the performance improvement is limited

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

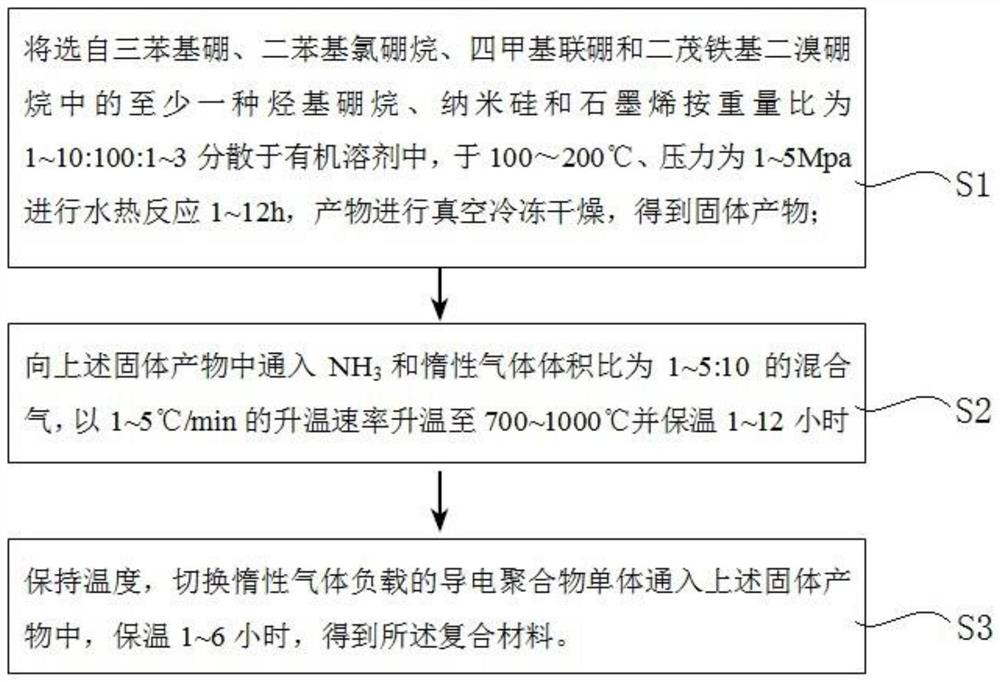

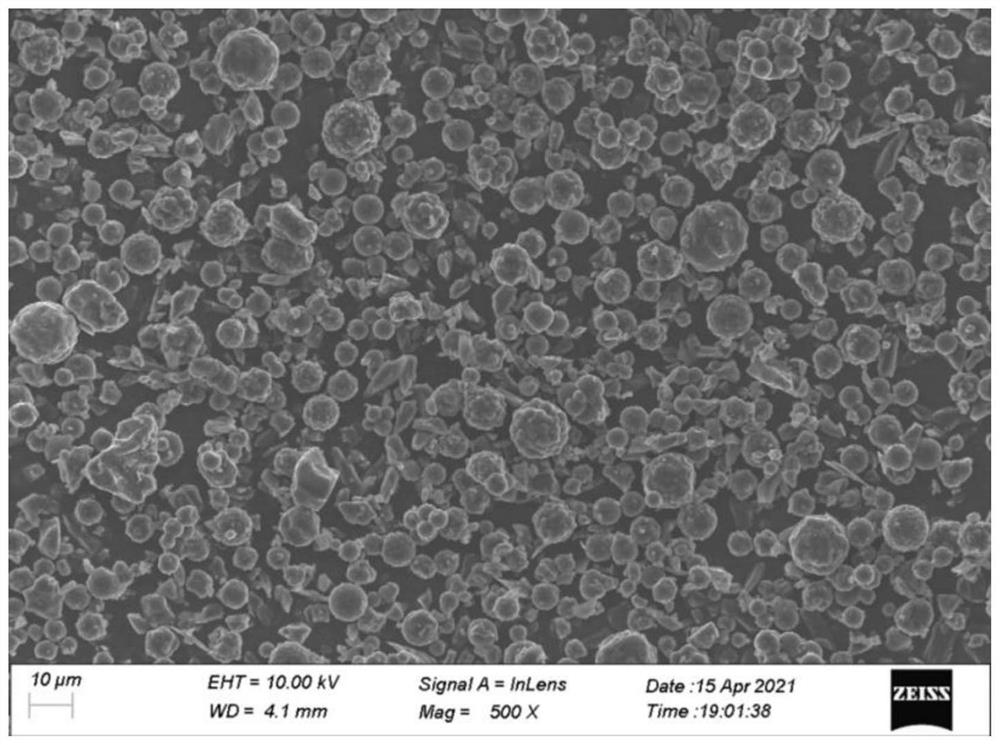

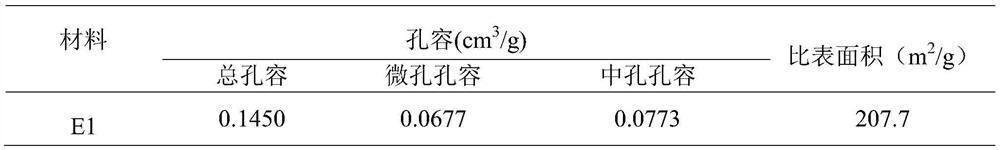

The embodiment of the present invention discloses a method for preparing a carbon-silicon composite material. By uniformly dispersing hydrocarbyl borane, nano-scale silicon powder and graphene, performing a hydrothermal reaction at 100-200°C, drying the product, and using NH3 and inert The mixed gas of the gas carbonizes the hydrothermal reaction product, and then passes through the conductive polymer monomer supported by the inert gas to react. The composite material has a core-shell structure, the inner core is an aggregation molding of nano-scale silicon powder, the inner core is doped with B elements, and the outer shell is doped with N and B elements. The core nano-scale silicon powder of the present invention is doped with boron by hydrothermal method to form a porous structure, which can reduce the expansion of silicon in the process of charging and discharging. Specific capacity and electronic conductivity, the shell layer is doped with a certain amount of boron and nitrogen elements, which is beneficial to the improvement of the specific capacity and the reduction of the impedance of the composite material.

Description

A kind of carbon-silicon composite material and its preparation method and application technical field [0001] The invention belongs to the field of lithium ion batteries, in particular to a carbon-silicon composite material and a preparation method and application thereof. Background technique Silicon carbon material has become the preferred material for high energy density negative electrode material due to its high energy density and wide sources. However, due to the high expansion of the silicon carbon material itself, some even as high as 200%, and the poor electrical conductivity, it affects the Its fast charging and low temperature performance limit its application. Under the same positive electrode material, namely under the same condition of N / P, improve the specific capacity of negative electrode material, on the one hand, can Reduce the areal density of the negative pole piece to improve its fast charging performance. On the other hand, less silicon carbon ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01M4/62H01M4/36H01M4/38H01M4/587H01M10/0525B82Y30/00B82Y40/00

CPCH01M4/362H01M4/386H01M4/587H01M4/624H01M4/628H01M10/0525B82Y30/00B82Y40/00H01M2004/021H01M2004/027Y02E60/10

Inventor 梁慧宇沈肖楠

Owner 常州烯源谷新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com