Rotor assembly and motor with same

A component and rotor technology, which is applied in the field of rotor components and motors with it, can solve the problems of lubrication, reduced wear, increased precision, increased reverse backlash of transmission structure, etc., and achieves the effect of preventing transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

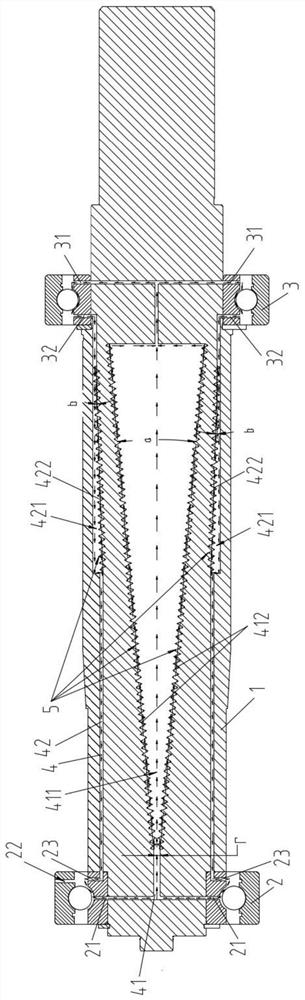

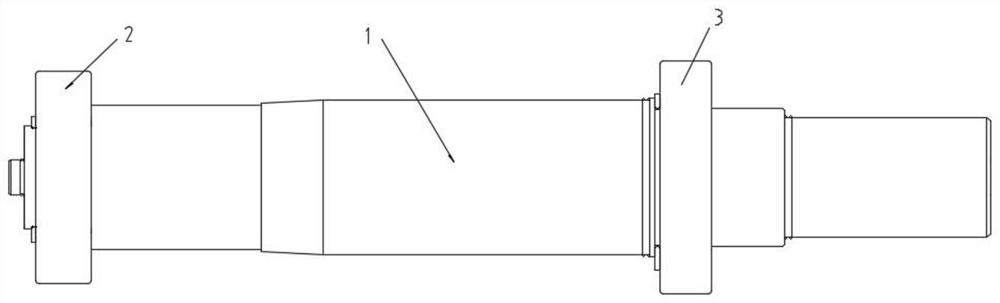

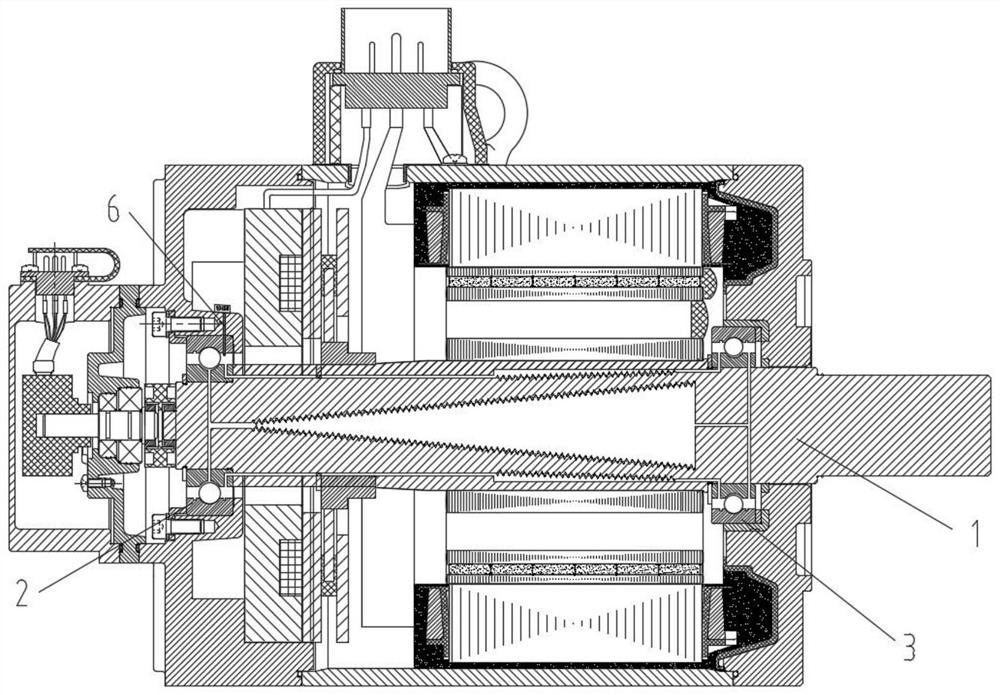

[0027] see in conjunction Figure 1-3 As shown, a rotor assembly includes: a rotating shaft 1, a first bearing part 2, a second bearing part 3 and an oil passage 4, and the first bearing part 2 and the second bearing part 3 are both arranged on the rotating shaft 1; the oil passage 4 It is used to transfer the heat generated by the first bearing part 2 and / or the second bearing part 3 to the rotating shaft 1 between the first bearing part 2 and the second bearing part 3, and disperse it through the continuous flow of grease in the oil passage 4 The heat generated by the first bearing part 2 and / or the second bearing part 3 can prevent the heat on the bearing from being transmitted to the end of the rotating shaft 1 . The first bearing part 2 is the rear bearing; the second bearing part 3 is the front bearing, when the oil passage 4 transfers the heat generated by the first bearing part 2 to the rotating shaft 1 between the first bearing part 2 and the second bearing part 3 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com